Rockwell Automation 1395 DC Drive, 800-1250 Hp, FRN 5.XX-9.30 User Manual

Page 83

Chapter 4

Installation

4-18

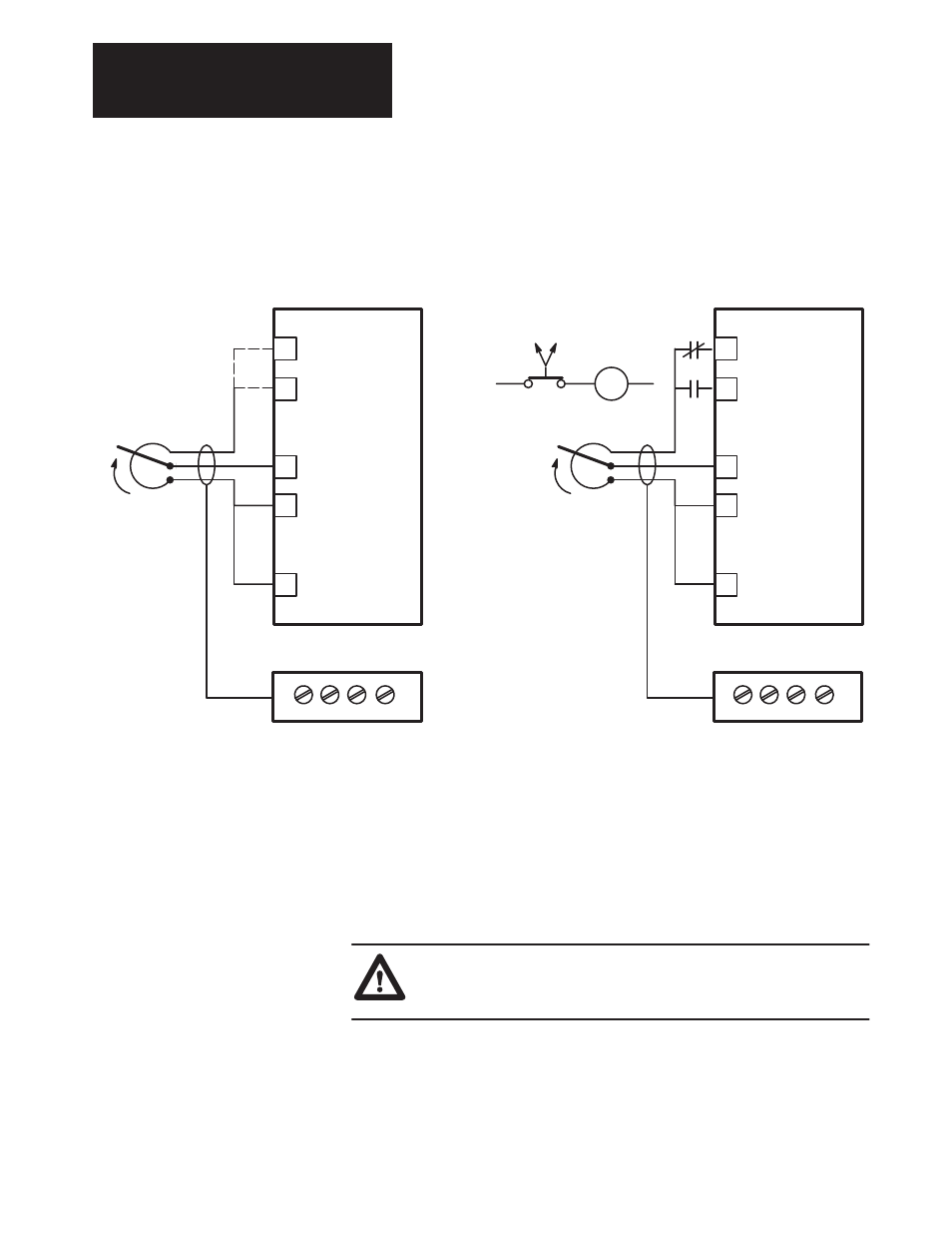

Analog Input – Velocity and Trim Reference. Connections for the

velocity and trim reference inputs can be for uni- or bi-directional

operation, using the internal drive

±

10VDC power supply (see Fig. 4.8).

Figure 4.8

Typical Analog Input Connections

31

32

+

–

33

TB3

+10V DC P.S.

–10V DC P.S.

ANALOG INPUT

P.S. COMMON

Bi-directional Operation

IMPORTANT: Connect

shield to drive end only.

Other end is to be insu-

lated and left floating.

Reference*

2.5k Ohm

Minimum

31

32

+

–

33

TB3

+10V DC P.S.

–10V DC P.S.

ANALOG INPUT

P.S. COMMON

TB10

Uni-directional Operation

IMPORTANT: Connect

to either terminal 31 or

32, Not Both

Reference*

2.5k Ohm

Minimum

R

R

Forward

Reverse

R*

Reverse Relay

* External to the Drive

*

TB10

Tach Velocity – The analog tachometer device generates a DC voltage that

is direction sensitive and proportional to speed. The tach output must be

connected to an analog input channel on the Discrete Adapter Board. Most

industrial tachs have an output greater than the

±

10V range of the analog

inputs. The tach output must be scaled down, by an external voltage

divider network, so that the entire speed range of the motor can be

represented by a

±

9V feedback signal.

ATTENTION: Connecting a tach which has an output range

greater than

±

10V directly to the analog input channel can

severely damage the adapter board.

The tach signal then must be scaled in the adapter board to determine the

proper relationship of output voltage/motor velocity to base speed in Drive

Units. This scaled configuration data must then be linked to Parameter 156

“Tach Velocity”.