Rockwell Automation 20-750-DNET PowerFlex DeviceNet Option Module User Manual

Page 71

Rockwell Automation Publication 750COM-UM002B-EN-P - October 2012

71

Using Explicit Messaging

Chapter 6

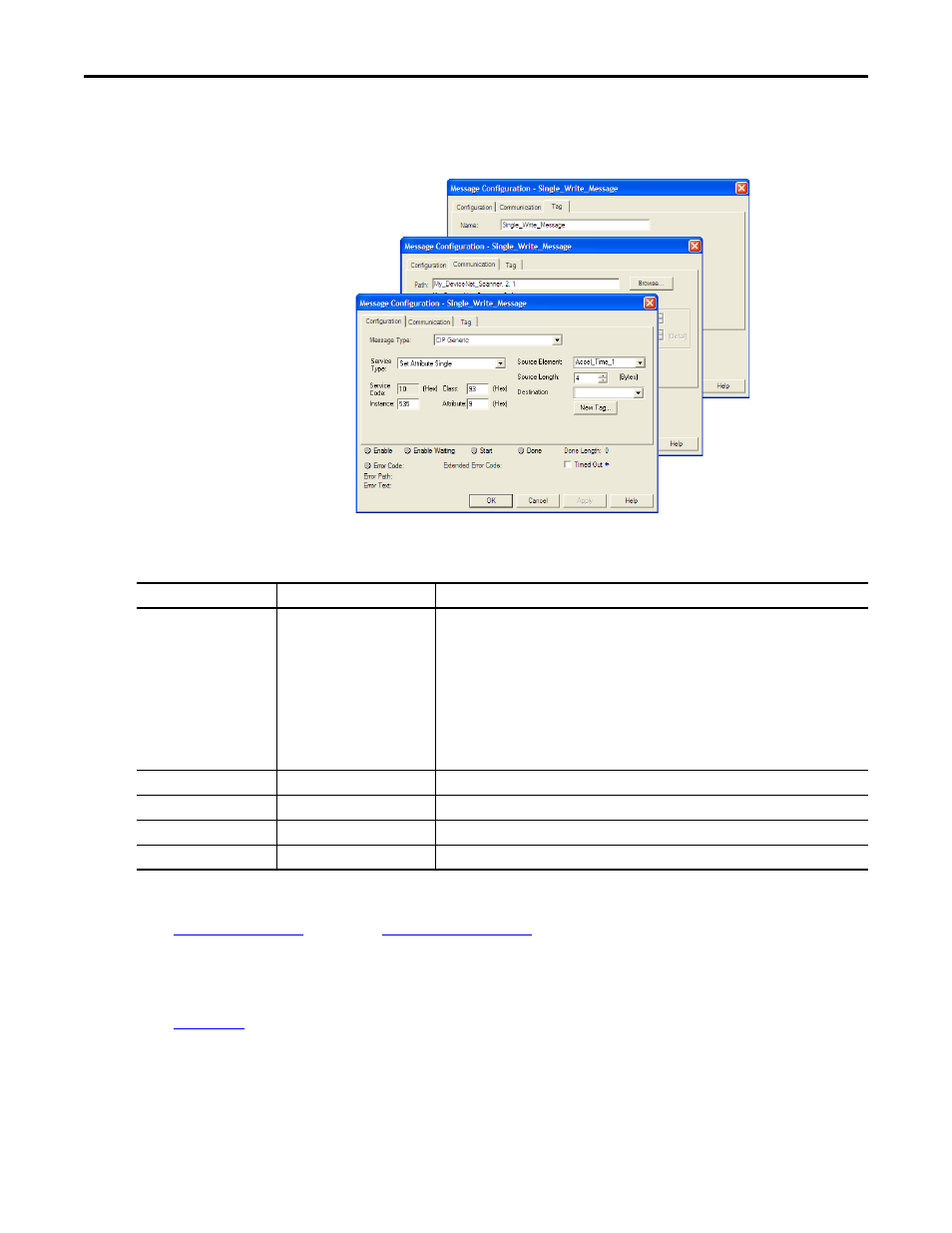

ControlLogix – Formatting a Message to Write a Single Parameter

Figure 16 - Set Attribute Single Message Configuration Dialog Boxes

The following table identifies the data that is required in each box to configure a

message to write a single parameter.

Configuration Tab

Example Value

Description

Message Type

Service Type

(1)

Service Code

(1)

Class

Instance

(2)

Attribute

(3)

Source Element

Source Length

Destination

CIP Generic

Set Attribute Single

10 (Hex.)

93 or 9F (Hex.)

(5)

535 (Dec.)

9 or A (Hex.)

Accel_Time_1

(6)

4 bytes

(6)

—

Used to access the DPI Parameter Object in the option module.

This service is used to write a parameter value.

Code for the requested service.

Class ID for the DPI Parameter Object.

Instance number is the same as parameter number.

Attribute number for the Parameter Value attribute.

Name of the tag for any service data to be sent from the scanner to the option module/drive.

Number of bytes of service data to be sent in the message.

Leave blank (not applicable).

Communication Tab

Example Value

Description

Path

(4)

My_DeviceNet_Scanner

The path is the route that the message will follow.

Tag Tab

Example Value

Description

Name

Single_Write_Message

The name for the message.

(1) The default setting for Service Type is ‘Custom’, enabling entry of a Service Code not available from the Service Type pull-down menu. When choosing a Service Type other than ‘Custom’

from the pull-down menu, an appropriate Hex. value is automatically assigned to the Service Code box which is dimmed (unavailable).

(2) The instance is the parameter number in the drive (Port 0). For example, to write to parameter 4 of a peripheral in Port 5 of a PowerFlex 755 drive, the instance would be 21504 + 4 = 21508.

DPI Parameter Object on page 109

(Class code 0x93) or

Host DPI Parameter Object on page 123

(Class code 0x9F) to determine the instance number.

(3) Setting the Attribute value to ‘9’ will write the parameter value to the drive’s Nonvolatile Storage (EEPROM) memory, which retains the parameter value even after the drive is power cycled.

Important: When set to ‘9’, the EEPROM may quickly exceed its life cycle and cause the drive to malfunction. Setting the Attribute value to ‘A’ will write the parameter value to temporary

memory, which deletes the parameter value after the drive is power cycled. When frequent write messages are required, we recommend using the ‘A’ setting.

(4) Click Browse to find the path, or type in the name of the device listed in the I/O Configuration folder (for this example, My_DeviceNet_Scanner). Then always type in a comma followed by

a ‘2’ which is the DeviceNet scanner port, followed by another comma, and then the node of the drive (for this example, ‘1’).

(5) See

Table 4 on page 66

for limitations of PowerFlex 750-Series drives when using DPI Parameter Object Class code 0x93 or Host DPI Parameter Object Class code 0x9F for explicit messaging.

(6) In this example, Accel Time 1 is a 32-bit REAL floating point parameter requiring the Data Type field to be set to ‘REAL’ when creating the controller tag. To write to a 32-bit integer

parameter, set the tag Data Type field to ‘DINT’. For a 16-bit parameter, set the Data Type field to ‘INT’. Also, the Source Length field on the Message Configuration dialog box must correspond

to the selected Data Type in bytes (for example, 4 bytes for a REAL or a DINT, or 2 bytes for an INT). See the drive documentation to determine the size of the parameter and its data type.