Maintenance/service – MacDon R80 Rotary Disc Pull-Type Windrower User Manual

Page 57

MAINTENANCE/SERVICE

Form # 169053

55

Model Year - 2009

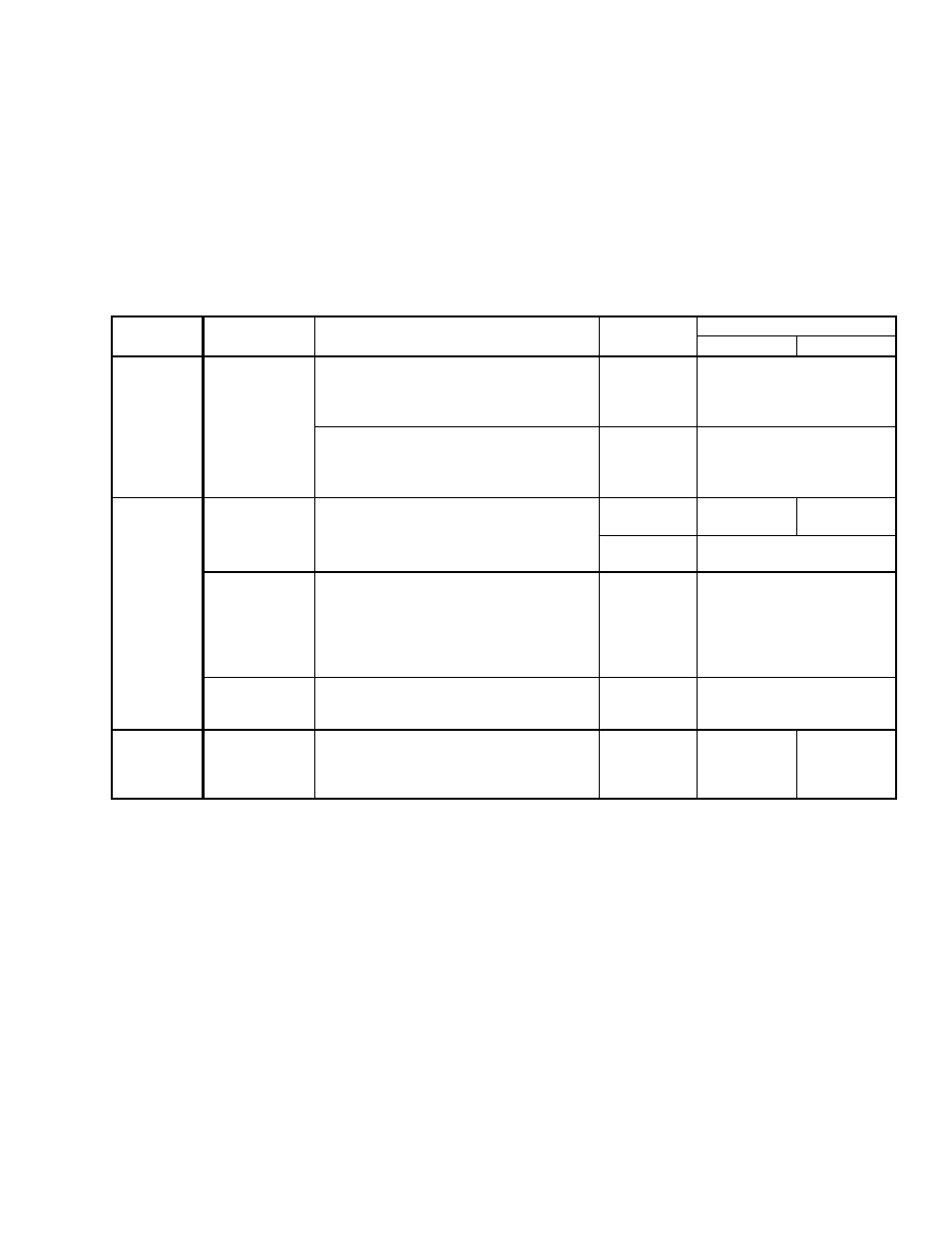

7.3.2 Recommended

Lubricants

Your machine can operate at top efficiency only

if clean lubricants are used.

• Use clean containers to handle all

lubricants.

• Store in an area protected from dust,

moisture, and other contaminants.

IMPORTANT

Do not overfill the cutterbar when

adding lubricant. Overheating and

failure of cutterbar components may occur

if overfilled.

CAPACITIES

LUBRICANT SPEC

DESCRIPTION

USE

13 Ft

16 Ft

High Temp. Extreme Pressure (EP2)

Performance With 1% Max Molybdenum

Disulphide (NLGI Grade 2).

Lithium Base

As Required

Unless

Otherwise

Specified.

--

Grease

SAE Multi-

Purpose

High Temp. Extreme Pressure (EP)

Performance With 10% Max Molybdenum

Disulphide (NLGI Grade 2).

Lithium Base

Driveline

Slip-Joints

--

Cutterbar

7 pints

(3.25 liters)

9 pints

(4.25 liters)

Traxon SAE

80W90

High Thermal & Oxidation Stability.

API Service Class GL-5

Pump Drive

Gearbox

2.1 qts (2.0 liters)

SAE 75W90

API Service

Class GL-5.

(SAE J2360

Preferred)

Fully Synthetic Gear Lubricant

Bevel

Gearbox

0.86 pints US (0.4 liters)

Gear

Lubricant

NLGI 00

Synthetic EP

Conditioner

Drive

Gearbox

Lubricated For Life

Hydraulic

Oil

Single Grade

Trans-

Hydraulic Oil *

** See Below For List of Recommended

Brand Names.

Hydraulic

Drive

Systems

39 gal. US

(147 liters)

48 gal. US

(180 liters)

* For Australian Units – Use SAE 15W40 complying with SAE specs for API Class SJ and CH-4 engine oil.

** The following oil company and equipment manufacturer brand names are recommended:

Petro Canada Duratran

Case IH Hy-Tran Plus®

John Deere Quatrol® J20C

Agco Power Fluid 821XL

** The following oil company and equipment manufacturer brand names are acceptable:

New Holland Hydraul

Esso/Exxon Hydraul 56

Shell Donax TD