Tensioning non-timed knife drive belts – MacDon D65 SP DHOM User Manual

Page 175

1.

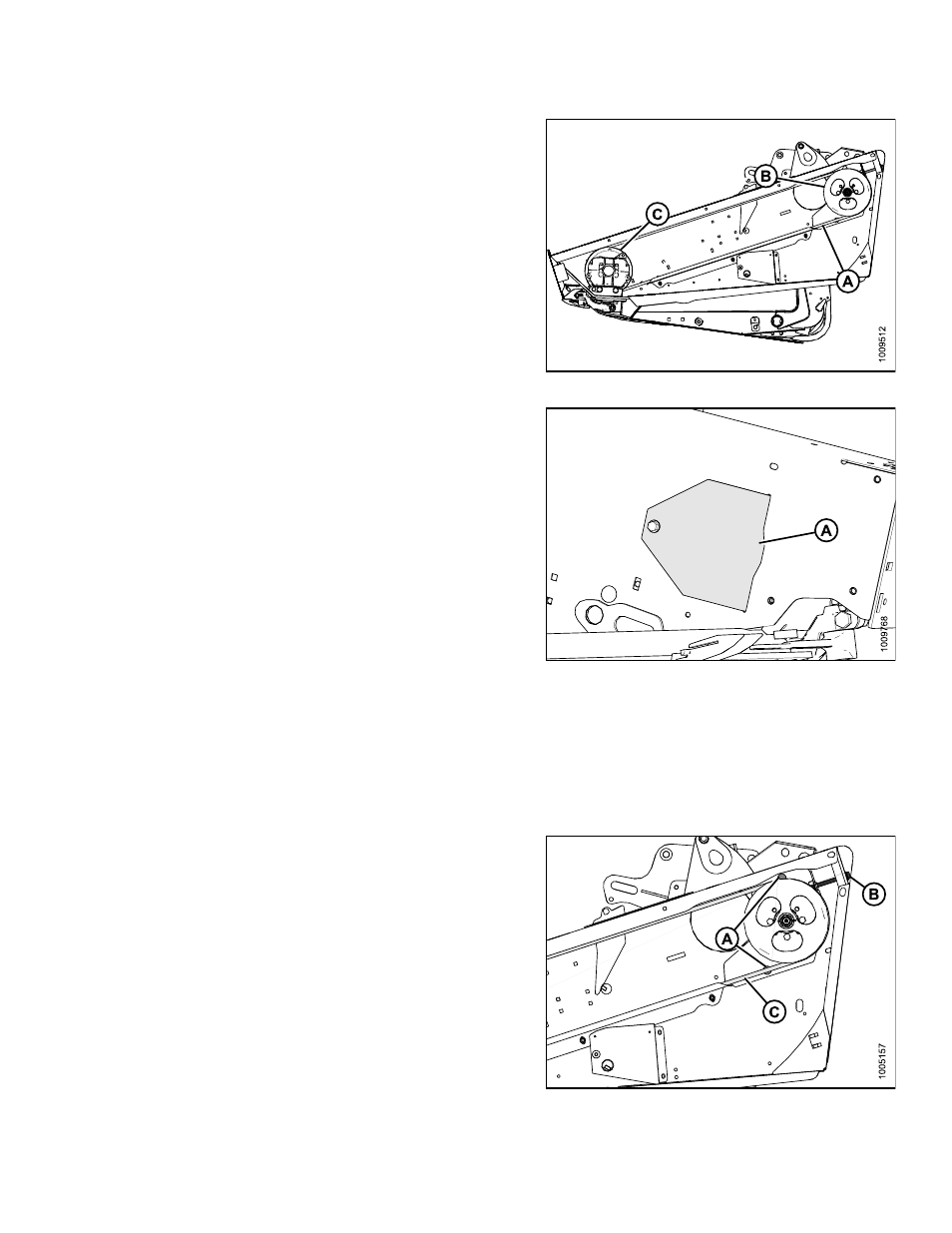

Route knife drive belt (A) around knife drive box

pulley (C) and knife drive pulley (B). Use notch in

pulley (C) to assist in installing belt.

NOTE:

When installing new belt, never pry belt over pulley. Be

sure drive motor is fully forward.

2.

Tension knife drive belt.

Refer to

Non-Timed Knife Drive Belts, page 163

Figure 6.72: Knife Drive

3.

Reinstall the access cover (A) and secure it with bolt.

4.

Close endshield. Refer to

Figure 6.73: Access Cover

Tensioning Non-Timed Knife Drive Belts

This procedure applies to single- and double-knife headers with non-timed drives.

IMPORTANT:

To prolong belt and drive life, do NOT overtighten belt.

1.

Open left endshield.

Refer to

2.

Loosen the two bolts (A) that secure the motor

assembly to header endsheet.

3.

Turn adjuster bolt (B) clockwise to move the drive

motor until a force of 20 lbf (80 N) deflects belt (C)

3/4 in. (18 mm) at mid-span.

Figure 6.74: Left-Hand Shown – Right-Hand

Opposite for Double-Knife Headers

169899

163

Revision A