Flare-type hydraulic fittings, Table 6.9 metric bolt bolting into cast aluminum – MacDon D65 SP DHOM User Manual

Page 132

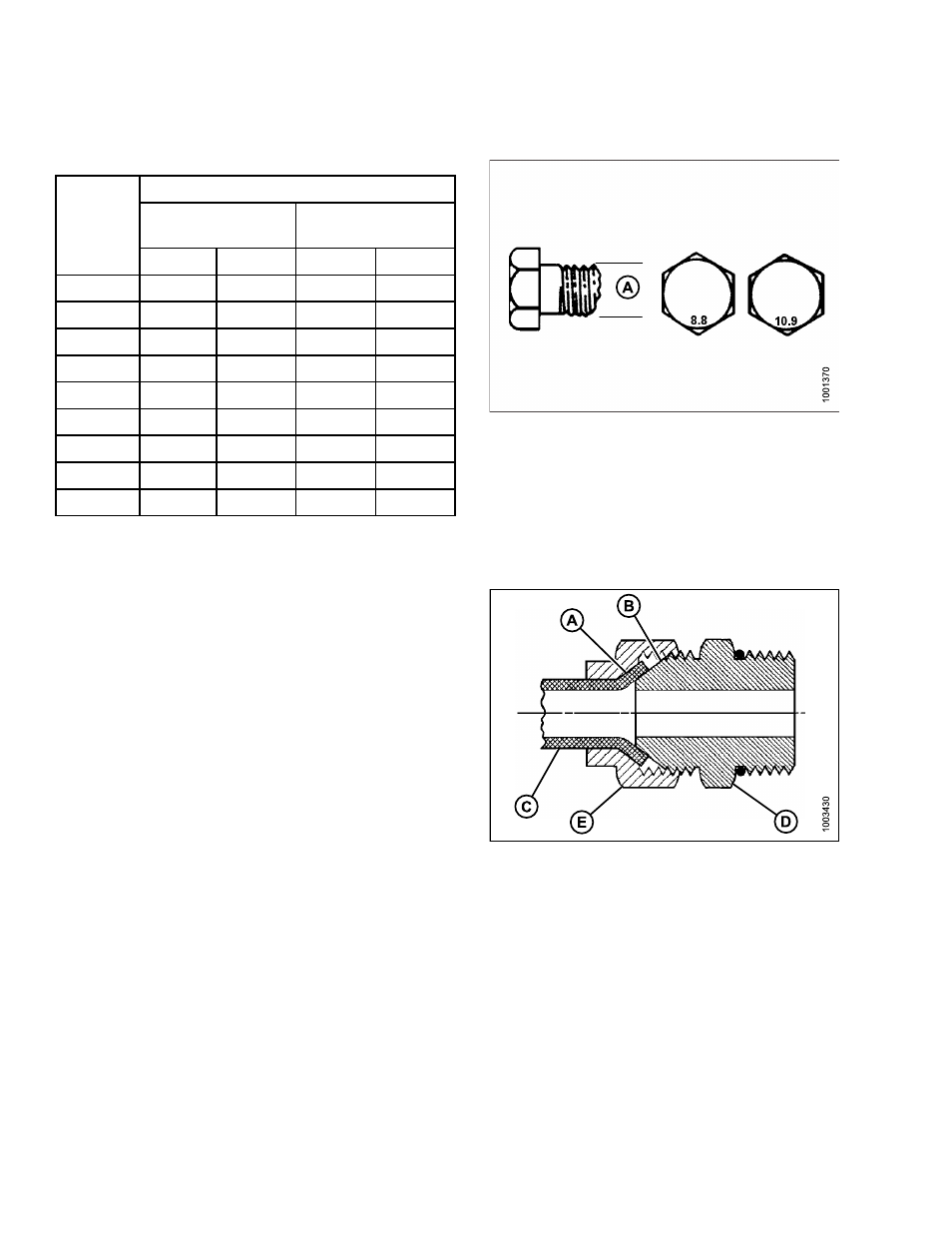

Metric Bolt Specifications Bolting into Cast Aluminum

Table 6.9 Metric Bolt Bolting into Cast Aluminum

Bolt Torque

8.8

(Cast Aluminum)

10.9

(Cast Aluminum)

Nominal

Size (A)

ft·lbf

N·m

ft·lbf

N·m

M3

–

–

1

–

M4

–

–

2.6

4

M5

–

–

5.5

8

M6

6

9

9

12

M8

14

20

20

28

M10

28

40

40

55

M12

52

70

73

100

M14

–

–

–

–

M16

–

–

–

–

Figure 6.9: Bolt Grades

Flare-Type Hydraulic Fittings

1.

Check flare (A) and flare seat (B) for defects that might

cause leakage.

2.

Align tube (C) with fitting (D), and thread nut (E) onto

fitting without lubrication until contact has been made

between the flared surfaces.

3.

Torque the fitting nut (E) to the specified number of

flats from finger tight (FFFT) or to a given torque

value shown in Table

6.10 Flare-Type Hydraulic Tube

.

4.

To prevent the fitting (D) from rotating, use two

wrenches. Place one wrench on the fitting body (D),

and tighten the nut (E) with the other wrench to the

torque shown.

5.

Assess the final condition of the connection.

Figure 6.10: Hydraulic Fitting

169899

120

Revision A