Map ae inc rate, Run time correction, Map_ae_inc_rate – Precision Turbo and Engine BigStuff3 GEN3 PRO SEFI System Hardware & BigComm Software User Manual

Page 91: Run_time_correction, Enter

BigStuff3 Pro SEFI System

Version 2.1 – February 2011

84

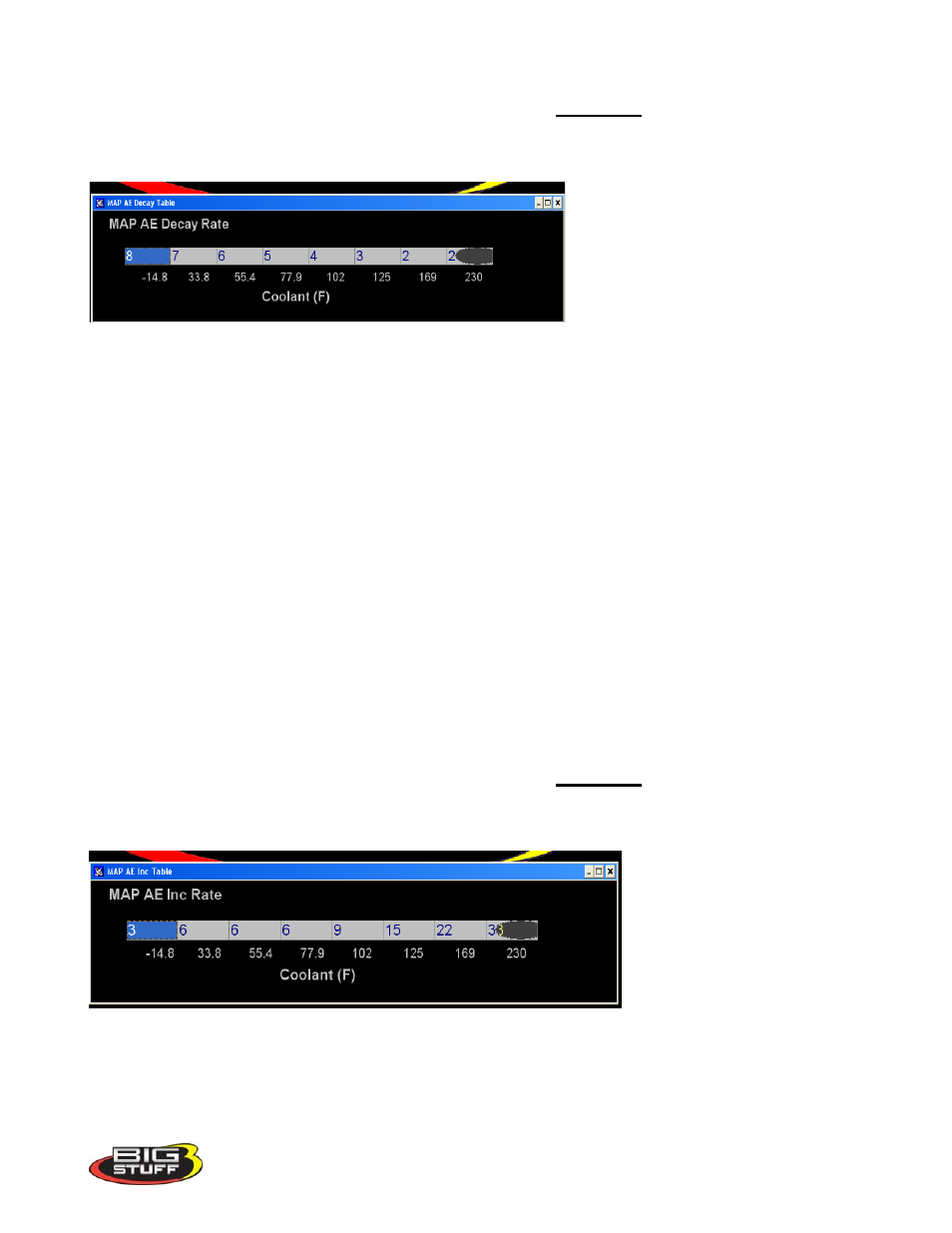

To change a value in the MAP AE Decay rate table, move the cursor using the PC’s mouse or arrow

keys to the cell to be changed. Input the desired value and hit

“Enter”

to save the change.

The inputs shown in the table below can be used as a baseline.

52. MAP AE Inc Rate

The fourth table is MAP AE Inc Rate. It is used to determine how quickly to increase the Negative

dMAP correction value after decelerating (throttle tip-out) the engine at a given coolant temperature.

A MAP AE Inc Rate of 3 represents 3 crank interrupts per 1 step increase of the dMAP Correction

until it reaches zero. In other words, if you input the number 3 into the table, after 3 crank interrupts

the dMAP Correction will increase 1 step. This 3 interrupt for 1 step process continues until the

dMAP correction reaches zero.

The fixed axis values in the MAP AE Inc Rate table represent coolant temperature, which increases

from left to right. The MAP AE Inc Rate table’s input values need to increase as coolant temperature

increases. The larger the value in the table, the slower the fuel is added.

While the engine is running, a “real-time Ellipse” will move within the MAP AE Inc Rate table

relative to the current engine Coolant Temperature “operating point”. Use it as a point of reference to

help calibrate the MAP AE Inc Rate table.

To change a value in the MAP AE Inc Rate table, move the cursor using the PC’s mouse or arrow

keys to the cell to be changed. Input the desired value and hit

“Enter”

to save the change

The inputs shown in the table below can be used as a baseline.

53. Run Time Correction

The fifth table is Run Time Correction. It only influences the Positive dMAP and dTPS Correction

Values for a short period of time after the engine is running. (i.e. up to 8 minutes). The Run Time