T-armor, Endlap – Metal Sales T-Armor Series User Manual

Page 62

© Metal Sales Manufacturing Corporation / Subject to change without notice 09/14

T-ARMOR

62

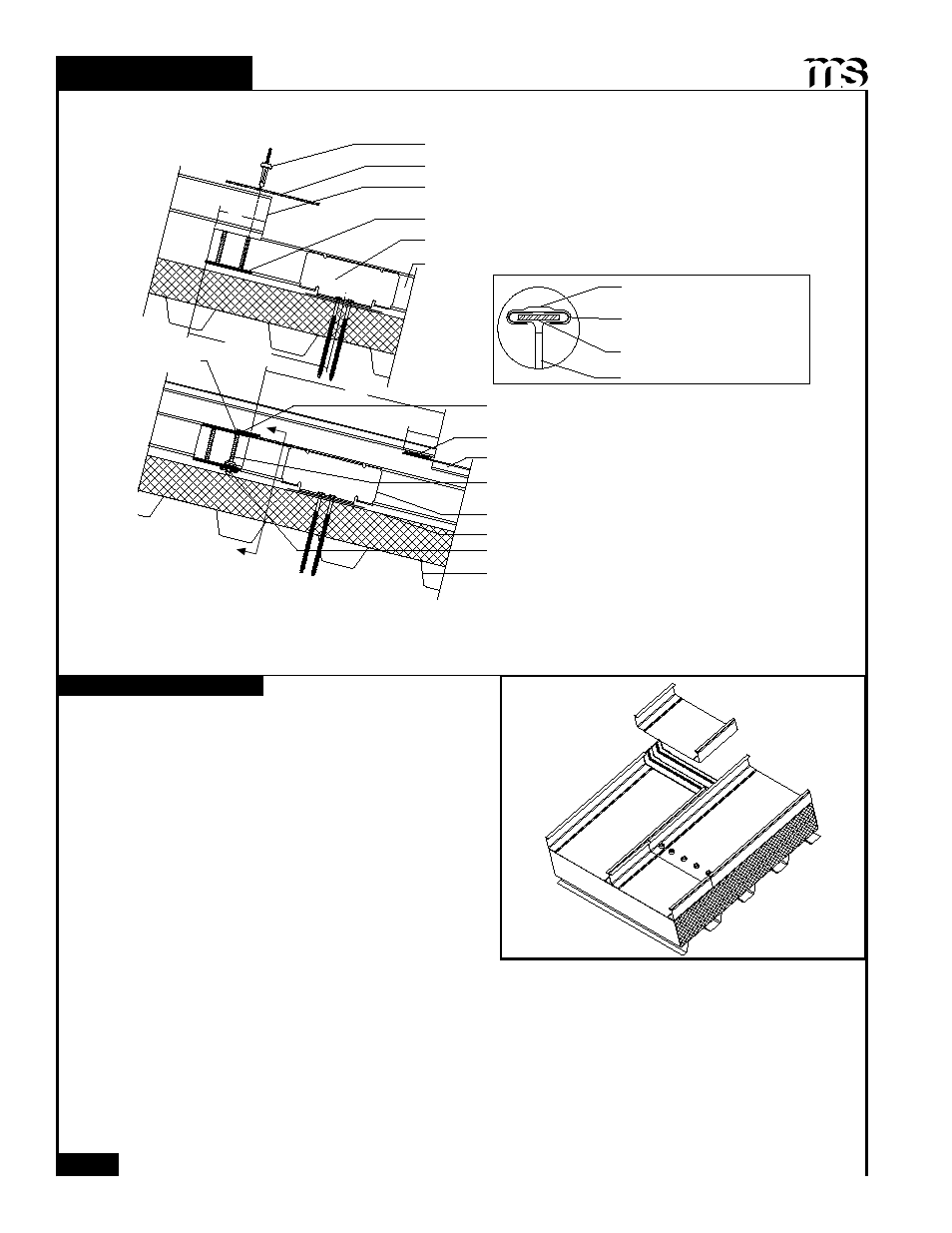

ENDLAP

INSTALLATION NOTES

Note: Panel Endlaps must be staggered a minimum of

24" and must be hand crimped before seaming.

1. Once the Eave Panel has been installed, apply two rows of

Endlap Pad (see page 51) across flat pan of the panel.

2. Apply a bead of Tube Sealant across each Endlap Pad

and up both vertical ribs.

3. Set the Peak Panel into place and nest with Eave Panel

so that the 3" factory notch is completely covered. (See

page 51 for complete details on installing endlapped

panels.)

4. Apply a bead of Tube Sealant at the butted ends of the

panel hems. Insert Stiffener Plate into butted panel hems

and set in the Tube Sealant.

5. Apply 2.5" Pig Tail of Endlap Pad and wrap around top of panel at butted ends, contacting Tube Sealant on the

panel rib.

6. Use a C-Clamp to hold panels in place. Drill hole and install

9

/

32

" Bulb-Tite Rivets (see page 52 for number of

fasteners and order).

7. Install Eave Cap, apply a bead of Tube Sealant across the width of the end of the notch and install the Peak

Cap. The Cap endlap must be located a minimum of 12" away from the panel endlap.

9

/

32

" Bulb-Tite Rivet (see page 52)

Stiffening Plate (set in Tube Sealant)

T-Armor Panel

Endlap Pad (2 Rows Set in the Pan) (see page 51)

Panel Clip w/ (2) #14-13 Deck Screws

T-Armor Panel (Factory-Notched for Endlap)

Pig Tail (Wrap Around Top of Panel at

Butted Ends of end lap)

Tube Sealant

Stiffener Plate

Panel Cap (Factory-Notched)

2 Rows of Tube Sealant (Across the

Pan and up Both Ribs)

Panel Clip w/ (2) #14-13 Deck Screws

Bearing Plate

9

/

32

" Bulb-Tite Rivet (see page 52)

A

A

3"

9" max

12"

1

/

2

:12 Slope

Minimum

*Can only be used with the

low and high clip systems

Metal Decking (By others)

Section A-A

T-Armor Panel

3

/

4

"x4"

Stiffener Plate 16 Ga.

2.5" Pig Tail (Wrap Around

Top of Panel at Butted Ends)

Panel Cap