6 communication interfaces, 1 usb interface – Memmert HPP 108/749 Constant climate chamber (Generation 2003) User Manual

Page 50

50

Advanced functions

Setting:

1. Set the desired humidity balance point in the SETUP (see page 42 ) and set the accompa-

nying compensation correction value to 0.0 %rh.

2. With a reference instrument, measure the deviation in the stationary state in the selected

humidity balance point.

3. Set the compensation correction value in the SETUP. If the measured reference humidity is

too low, the compensation correction value must be set with a negative sign.

4. Perform a control measurement with the reference instrument.

The procedure can be performed with humidity balance points of 20 % rh and 90 % rh.

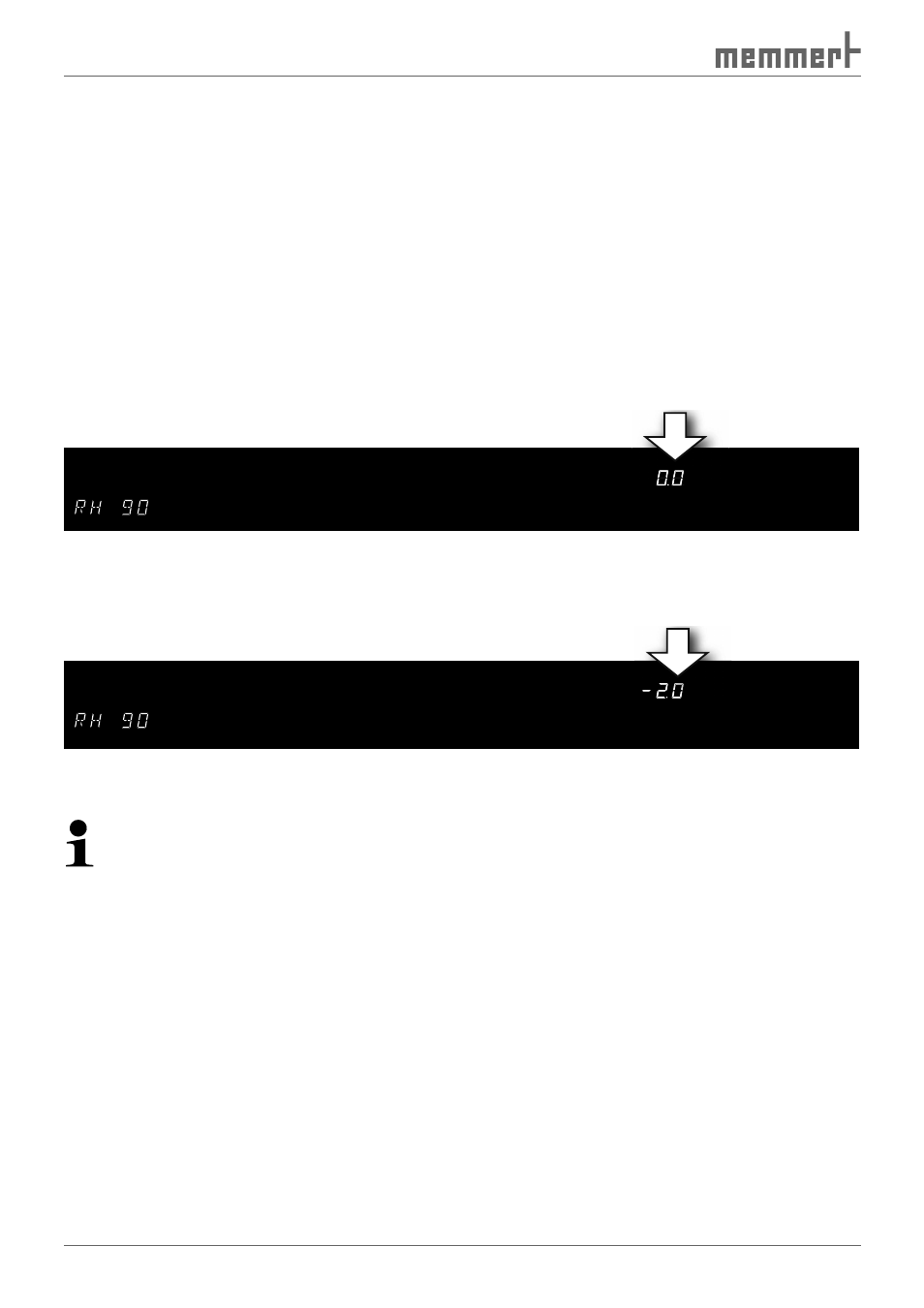

Example: Humidity deviation at 90 % should be corrected.

1. Set humidity balance point in the SETUP to RH 90 and set the accompanying compensation

correction value to 0.0 % rh:

SETUP

loop

t3

t4

t2

t1

on

off

Mo

Tu

We

Th

Fr

Sa

Su

3

4

2

1

STERI

DEFRO

°C

°C

rh

mb

%

CO

mb

2

IN 1

IN 2

OUT

MIN

AUTO

MAX

rh

b

%

%

%

2. With a calibrated reference instrument, an actual humidity of 88 % rh is measured at nor-

mal operation, with a set setpoint humidity of 90 % rh.

3. Set the compensation correction value in the SETUP for RH 90 to –2.0 % rh:

SETUP

loop

t3

t4

t2

t1

on

off

Mo

Tu

We

Th

Fr

Sa

Su

3

4

2

1

STERI

DEFRO

°C

°C

rh

mb

%

CO

mb

2

IN 2

OUT

IN 1

IN 2

OUT

MIN

AUTO

MAX

rh

rh

mb

%

%

%

%

%

IN 2

OUT

4. The reference instrument should display 90.0 % rh after the calibration procedure.

With RH 20, a further comparison can be programmed at 20 % relative humidity.

If all compensation correction values are set to 0.0 % rh, the factory calibration settings

are restored.

7.6

Communication interfaces

Depending on the model, the constant climate chamber can be fitted with different commu-

nication interfaces (USB, RS 232/485, Ethernet). These are located on the rear of the appliance.

7.6.1 USB interface

The chamber is fitted by default with a USB interface in accordance with the USB specification.

With this interface it is possible to control and log the chamber remotely from the computer.

For this, the “Celsius“ software is used.

The chamber must be given a unique device address in the SETUP submenu, menu item AD-

DRESS, via which the computer communicates with the oven (see page 42 ). The default setting

is ADDRess 0. Using this, the appropriate incubator can be selected and programmed from the

computer.

If several chambers are to be connected to a computer via USB interface, an appropriate inter-

face on the computer and a separate cable are required for each chamber.

The maximum cable length is 5 m.