INFICON SQC-122 Thin Film Deposition Controller Operating Manual User Manual

Page 6

Chapter 1

Quick Start

1-7

1.0 Introduction

The SQC-122 is a multi-channel quartz crystal monitor and deposition controller. It

measures up to six 1MHz to 6 MHz quartz crystal sensors, and controls two evaporation

sources. Twenty-five processes, consisting of 250 layers and 25 materials, can be

stored for easy retrieval. Eight process control relays, and eight digital inputs are easily

configured to support a broad range of external functions, including source pocket

rotation.

The SQC-122 can also be controlled via the standard RS-232 interface and Windows

control program. An optional handheld remote power control is also available.

This chapter will aid you in the initial setup and operation of your system. Please review

the entire manual for detailed operational, programming, and safety information.

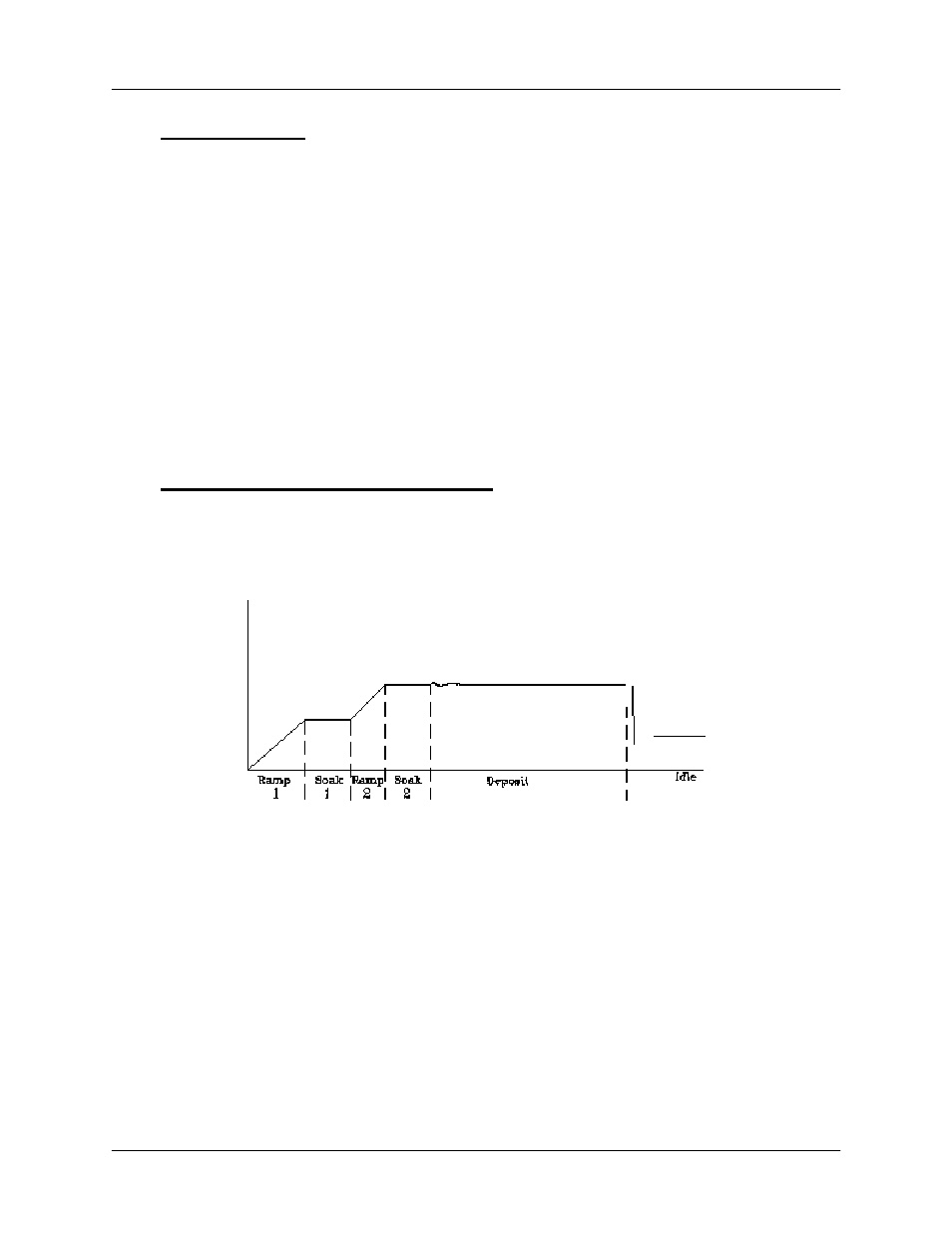

1.1 Thin Film Process Overview

The SQC-122 stores the recipes, and provides the operating functions, required to

control thin film deposition processes. A typical thin film deposition cycle is shown

below.

The cycle can be broken into three distinct phases: pre-conditioning (ramp/soak),

deposition, and post-conditioning (feed/idle). During pre-conditioning, power is supplied

to prepare the evaporation source for deposition. Once the pre-conditioning period

expires, material deposition begins. During deposition, the PID loop adjusts the

evaporation source power as required to achieve the desired deposition rate. When the

desired thickness is reached, the evaporation source is set to idle power. At this point

the process may be complete, or deposition of another film layer may begin.