Glossary of alarm terms – Despatch Protocol 3 Controller User Manual

Page 52

W

ORKING WITH

O

PERATING

M

ODES

Protocol 3 Controller

Owner’s Manual

52

Version 1.2

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

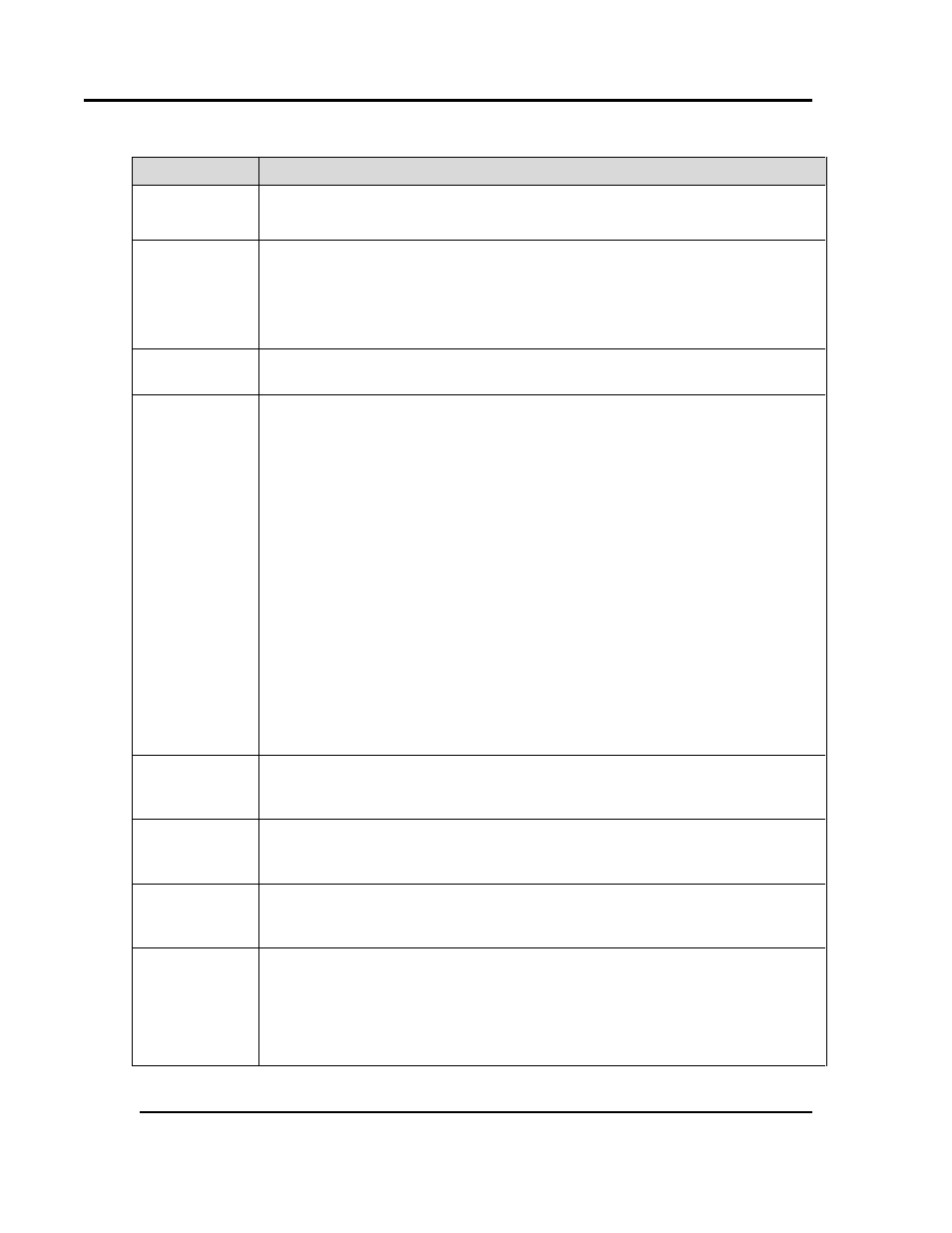

5.6.1.5. Glossary of Alarm Terms

Term

Description

Alarm

Hysteresis

Alarm hysteresis is the deadband on the safe side of an alarm (that is, the side

of the alarm that is below the high alarm value or above the low alarm value).

The signal must pass through this deadband before the alarm deactivates.

Alarm Inhibit

(Not functional

on Firmware

2.3 or lower)

Alarm Inhibit prevents unwanted process or deviation alarm activation at power-

up or when the controller setpoint is changed. The alarm activation is inhibited

until a safe condition is present. The alarm operates normally from that point on.

For example, when the alarm is inhibited, a low alarm will not activate at power-

up until the process value first rises above the alarm point than falls back below.

Input Signal

Break Alarm

If the signal from the process value input is broken the process value will

display OPEN and the alarm will activate.

Loop Alarm

A loop alarm detects faults in the control feedback loop by continuously

monitoring process variable response to the control output(s). If one of the five

alarms is defined to be a loop alarm, it repeatedly checks if the PID control

output is at saturation. If saturation is reached (0% or 100% power for single

control type), an internal timer is started. Thereafter, if the output has not

caused the process variable to be corrected by a predetermined amount (V)

after time (T) has elapsed, the alarm becomes active.

Subsequently, the alarm repeatedly checks the process variable and the PID

output. When the process variable starts to change value in the correct sense

or when the PID output is no longer at the limit, the alarm is deactivated.

For PID control, the loop alarm time (T) can be automatic (twice the Integral

Time value) or set to a user defined value. Correct operation with the automatic

loop alarm time depends upon reasonably accurate PID tuning. The user

defined value is always used for On-Off control, and the timer starts as soon as

an output turns on.

The value of V depends on the input type. For Temperature inputs, V = 2°C or

3°F. For Linear inputs, V = 10 x LSD (Least Significant Digit

—smallest

incremental value that can be show at the defined display resolution).

% Memory

Used Alarm

The Protocol 3 controller can record data at a set interval. If the percentage

selected of the memory capacity of the recorded data is exceeded the alarm will

activate.

Process Value

Alarms

Three types of process alarms are implemented in the Protocol 3: High, Low,

Band. If the process variable passes the boundary, the alarm activates as

depicted in

PV-SP

Deviation

Alarm

The control subtracts the process value from the setpoint. If the resulting value

exceeds the alarm value setting the alarm will activate.

Signal Change

Per Min Alarm

An alarm based on the rate of change in the measured process variable. If the

PV changes at a rate greater than the alarm level per minute, the alarm will

activate. The rate of change must be above the alarm threshold for longer than

the Minimum Duration Of Change time, before the alarm will change state.

Caution: If the duration is less than this time, the alarm will not activate no

matter how fast the rate of rise.