Outputs, Remote communication – Despatch Protocol 3 Controller User Manual

Page 16

T

HEORY OF

O

PERATION

Protocol 3

Controller Owner’s Manual

16

Version 1.2

Copyright © 2013 by Despatch Industries.

All rights reserved. No part of the contents of this manual may be reproduced, copied or transmitted in any form or by any

means including graphic, electronic, or mechanical methods or photocopying, recording, or information storage and

retrieval systems without the written permission of Despatch Industries, unless for purchaser's personal use.

3.1.2. Outputs

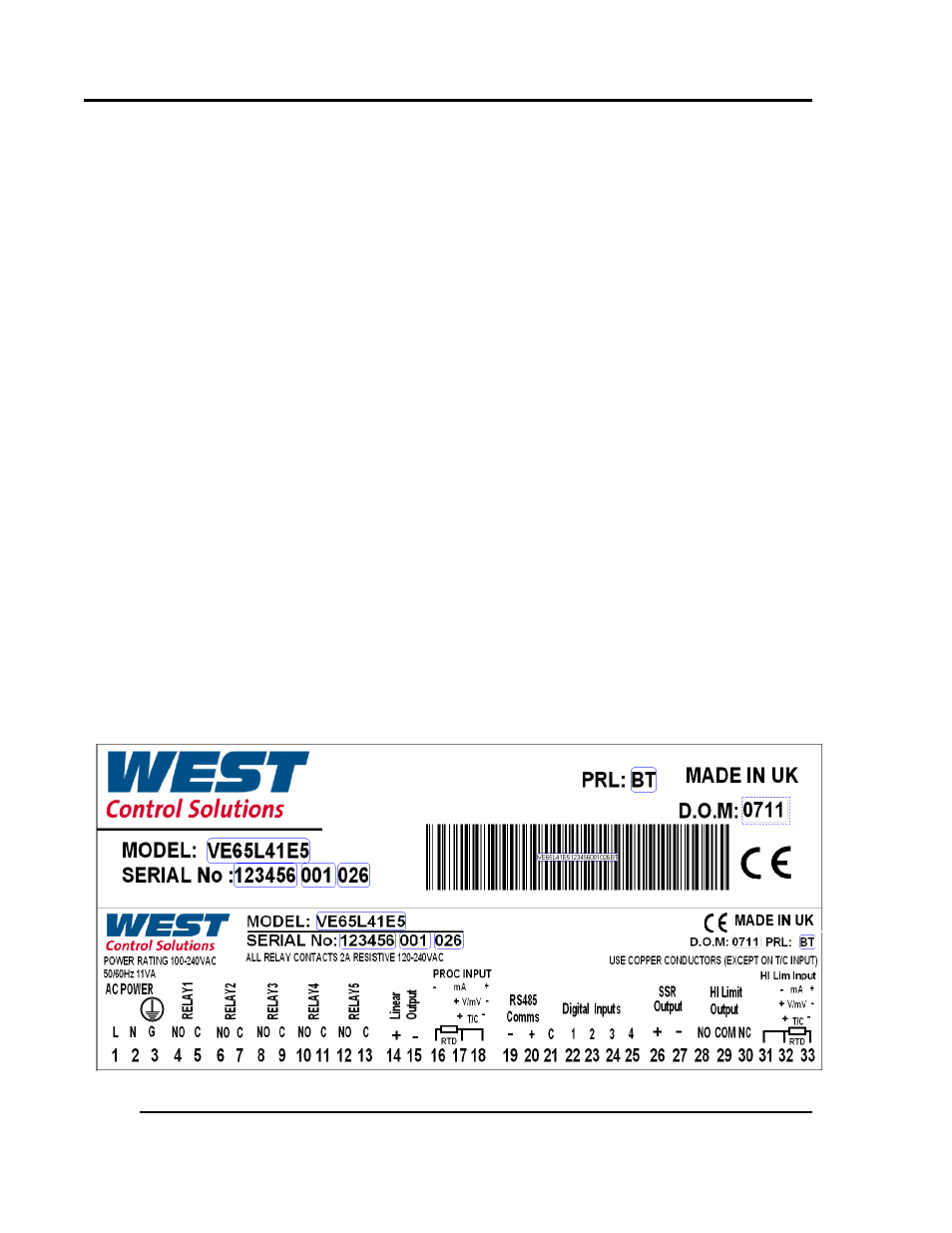

The Protocol 3 controller comes standard with an output signal that can transmit temperature

data, setpoint data or control power to a user-supplied recording device. Output relays (five) can

also signal user-specified events or alarm to external devices (Figure 2 and Figure 3).

Heating output: The control output is a DC voltage open-collector output which is

time-proportioned and designed to control a heat control device such as a solid state relay.

High limit: The high limit output is a SPDT relay which is energized under normal operating

conditions. If the control senses a temperature higher than the high limit setpoint, or if there is

a sensor error, the high limit relay will de-energize until the condition is cleared and

Reset

is

pressed. When the high limit relay is de-energized, the heater is disabled.

Retransmission: The retransmission output is a signal that is proportional to the process

temperature, setpoint or control power:

o 0-5V

o 0-10V

o 2-10V

o 020 ma

o 4-20 ma

o 0-10VDC Power Supply

The signal can be an input to other devices such as a chart recorder.

Relays: The five SPST dry contact relay outputs can be configured to function as alarms,

events, or end of cycle. These outputs can be utilized in Manual, Timer or Profile Modes.

3.2. Remote Communication

When used with a PC running Protocol Manager™ software, the Protocol 3 controller allows an

operator to remotely control the oven, download recipes and log data.