6 pump/lift/mast, 6 pump/lift/mast -5, Lift system -5 – JLG 1230ES Service Manual User Manual

Page 35

SECTION 3 - THEORY OF OPERATION - 1230ES

3121222

– JLG Lift –

3-5

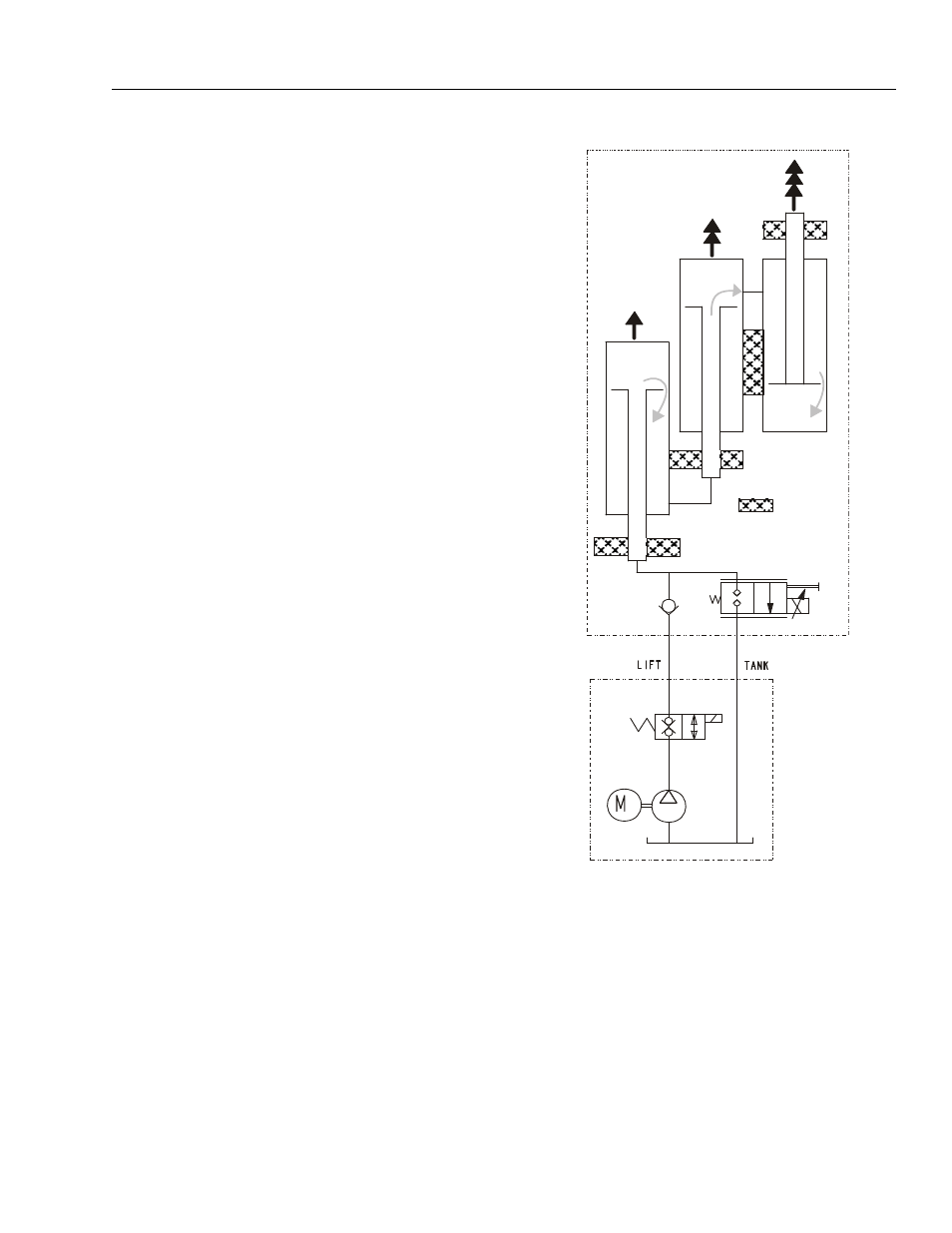

3.6 PUMP/LIFT/MAST

An electrically driven hydraulic pump provides hydraulic

pressure to actuate the steering and lift up. Lift down is

"powered" by gravity. The lift actuator is a three stage

hydraulic cylinder. The cylinder pistons are not sealed so

fluid can flow from one cylinder to the next. The area of the

piston that fluid touches on both sides does not provide

lift because the forces on both sides cancel each other.

The area of the piston with the rod behind it provides the

lifting force necessary because no pressure is there to

cancel the force applied by the pressure on the other side.

To lift the platform, the solenoid energizes and opens the

lift up valve. The pump speed is set proportional to joy-

stick position. Fluid flows into the first cylinder, through the

hollow rod. This extends the barrel of the first cylinder. The

rod to the second cylinder is attached to the barrel of the

first cylinder. Fluid is passed by a port in the first cylinder

to the hollow rod of the second cylinder. That extends the

second cylinder. The barrel of the second cylinder is

attached to the barrel of the third cylinder. A port in the

barrel of the second cylinder passes fluid to the third cylin-

der. This extends the third cylinder, and lifts the platform.

To bring down the platform, the lift down valve opens, pro-

portional to joystick position, and allows fluid out of the

cylinder, allowing it to retract by gravity.

Figure 3-4. LIFT SYSTEM

The Power Module is essentially a "low-side" switch for the

pump motor. The positive terminal of the pump is tied to

Battery Positive after the Line Contactor. The negative ter-

minal of the pump connects to the P Terminal of the Power

Module, which switches current through MOSFET transis-

tors to the Battery Negative.

For variable speed pump operation, the MOSFET transis-

tors switch On and Off at high frequencies (16kHz). The

Duty Cycle is varied to control the voltage applied to the

pump motor. When the MOSFET's spend 50% of the

period On and 50% Off, approximately ½ of the available

Battery power will be applied to the pump motor. Similarly,

the MOSFET are On continuously (100% Duty Cycle) to

PLATFORM

ATTACHMENT

CHASSIS