4 controls & sensors, Elevation, Joystick – JLG 1230ES Service Manual User Manual

Page 33: Tilt, 5 traction, 4 controls & sensors -3, Elevation -3 joystick -3 tilt -3, 5 traction -3, 4 controls & sensors elevation

SECTION 3 - THEORY OF OPERATION - 1230ES

3121222

– JLG Lift –

3-3

3.4 CONTROLS & SENSORS

Elevation

The elevation sensor is an inductive proximity switch. It

must be powered to operate. There is a 1.3k Ohm resistor

where it connects to the ground module to produce the

proper signal for the ground module. (See electrical sche-

matic in Section 9 for details.) If Ferrous material is pres-

ent, i.e. the mast is fully retracted, it will close. The sensor

is calibrated mechanically.

The control system uses a combination of the elevation

proximity switch and pothole protection switches to deter-

mine if the platform is elevated. If these sensors do not

agree a fault is thrown.

Joystick

The joystick is used to "command" both lift and drive. The

Lift/Drive switch selects which one is applicable. This

command may be modified by the control system based

on interlocks and personalities.

On the joystick there are three switches and the control

handle. The joystick control handle sensor is not a simple

potentiometer. There is a position sensing element, and

signal conditioning circuitry in it to generate the position

signal. It is powered by 5VDC supplied from the platform

controller. When centered it will output approximately

2.5VDC. Fully forward, it will output approximately 1 VDC.

Fully backward, it will output approximately 4 VDC. On the

handle is the trigger switch that must be depressed in

order to operate the vehicle. This prevents unintentional

movement. To pass start-up tests the three switches must

be open and the joystick must be centered.

Joystick personalities to define the centered position

(where command is 0%), minimum and maximum for-

ward, as well as minimum and maximum reverse can be

accessed. Joystick system Personality settings can be

changed via ANALYZER -> PERSONALITIES -> ACCEL-

ERATOR as follows:

• FWD MIN - The forward extent of the centered position.

Values between this and REV MIN are where 0% is

commanded.

• REV MIN - The reverse extent of the centered position.

Values between this and FWD MIN are where 0% is

commanded.

• FWD MAX - Joystick voltage where 100% will be com-

manded.

• REV MAX - Joystick signal voltage where -100% will be

commanded.

Tilt

The control system monitors the tilt sensor to determine if

the vehicle is tilted excessively. This condition is called

"Tilted". In the CE, Australia and Japan markets, if the vehi-

cle tilt angle in any direction is greater than or equal to

3.5°, the control system considers the machine tilted. In

other markets, the vehicle is considered Tilted if the vehi-

cle tilt angle front to back is greater than or equal to 3.0°

or tilt left to right is greater than or equal to 1.5°.

3.5 TRACTION

The traction, or drive system, moves the vehicle along the

ground by electric motors. The Armatures (rotating wind-

ings) of the separately-excited drive motors are wired in

parallel to the Power Module's M1 and M2 terminals. The

M1 Terminal is always at the same voltage as the +B (Bat-

tery Voltage when the Line Contactor is closed) and

allows the module to measure current with the internal

shunt (extremely low impedance). The M2 Terminal is

pulled to Ground by the Armature Switch MOSFET's (con-

nected to -B Terminal).

To provide variable speed control, the Armature MOSFET

transistors switch On and Off at high frequencies (PWM/

pulse-width modulation; 16kHz). The Duty Cycle (On & Off

time) is varied to control the voltage applied to the Arma-

tures. When the MOSFET's spend 50% of the period On

and 50% Off, approximately ½ of the available power will

be applied to the Armatures (50% Duty Cycle). Similarly,

the MOSFET are On continuously (100% Duty Cycle) to

apply all available Battery power to the Armatures (as in

Driving at Full Speed).

Instead of permanent magnets, the separately-excited

drive motors use electro-magnets (called Field Windings)

located in the stator (non-rotating) portion of the motor.

Field windings are preferable to permanent magnets

because the Power Module can adjust the stator's magne-

tism for optimum motor performance. When climbing a

grade at low speeds, the Power Module may apply as

much as 40A to the field windings for more electro-motive

force. On level terrain, the Power Module will apply as little

as 14A to the fields for higher rotational speeds and better

electrical efficiency.

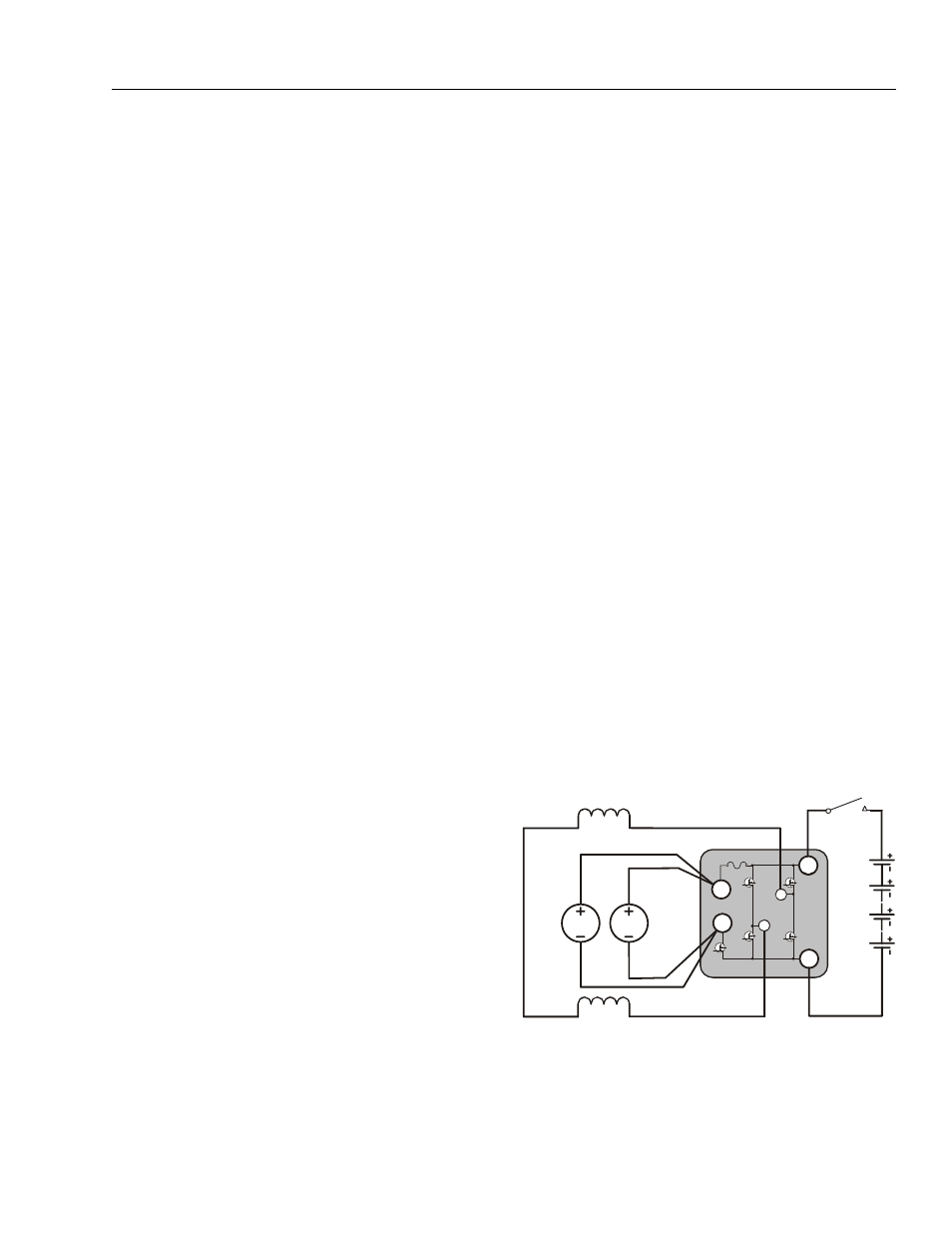

Figure 3-2. Drive Motors Schematic - 1600346 (SEV-

CON) Power Module

Line Contactor

24V

+B

–B

F2

F1

M2

M1

Power Module

Left Field Winding

Right Field Winding

Armature

Switch

Field

Switches

Shunt

1

3

2

4

Left

Armature

Right

Armature