Poison Spyder DANA 44 BOMBSHELL User Manual

Installation instruc tio ns, Dana 30 & dana 44 bombshell installation

INSTALLATION INSTRUC

TIO

NS

©2014 POISON SPYDER CUSTOMS, INC. • 951-849-5911 • WWW.POISONSPYDER.COM

DANA 30 & DANA 44 BOMBSHELL INSTALLATION

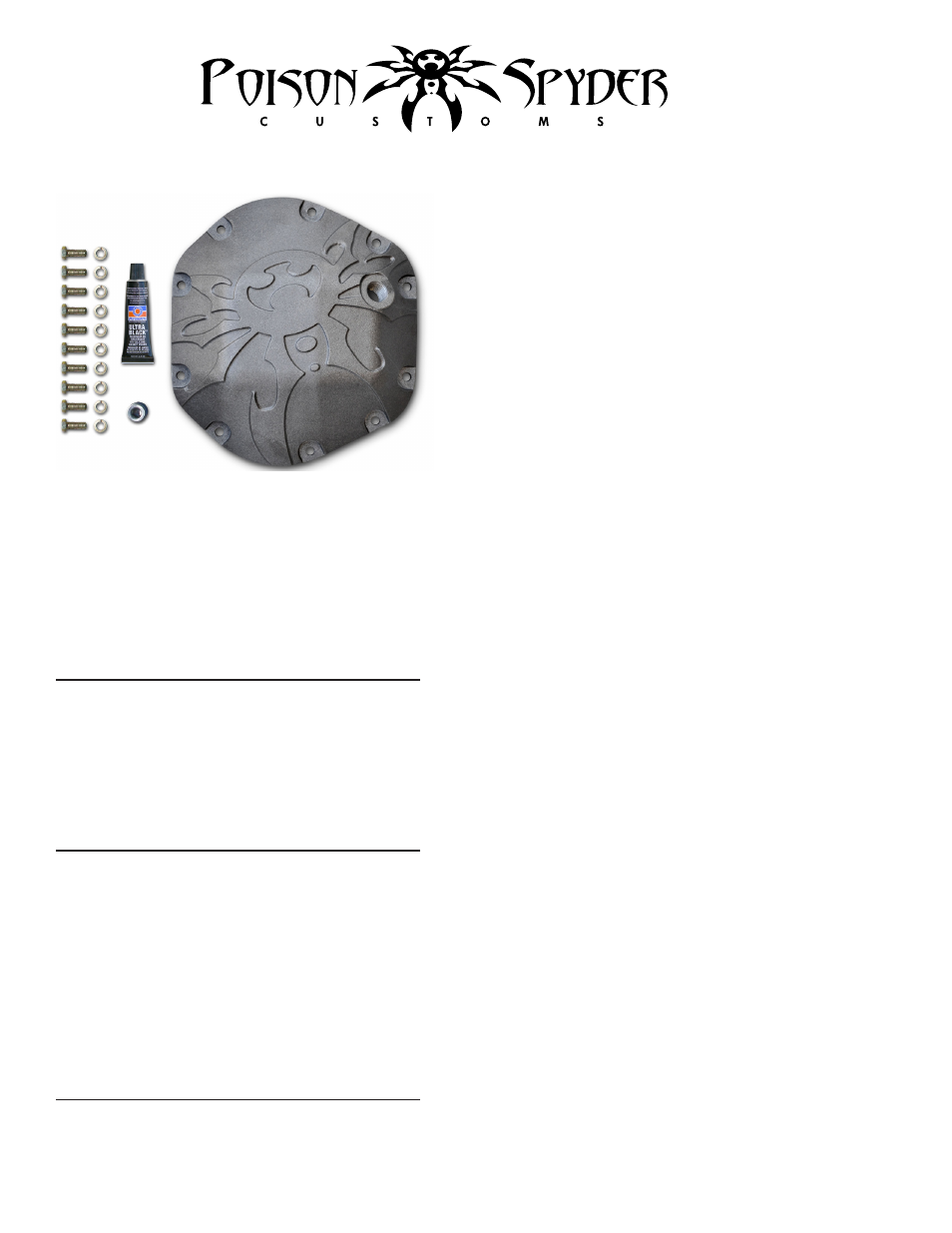

Poison Spyder Customs’ Bombshell differential

covers are designed to protect your differential’s

internals from damage due to menacing trail

obstacles. Bombshells prevent cover peel back

and fluid loss from broken seals. The design of

the Bombshell also protects the bolt heads from

trail damage while acting as a ramp, or skid, to

help ease you over obstacles.

PARTS LIST

(1) Bombshell differential cover

(1) Fill plug

(1) Tube silicon sealant

(10) 5/16-18 X 7/8” gr8 hex head cap screws

(10) 5/16” gr8 split lock washers

TOOLS & SUPPLIES NEEDED

• 1/2” box end wrench or socket & ratchet

• Medium shop hammer & Chisel or pry bar

• 3/8” hex key

• Oil drain pan

• Gasket scraper or wire wheel

• Brake cleaner

• Gear oil

• Teflon tape or pipe thread sealer

INSTALLATION PROCEDURE

1. Park vehicle on flat level surface. Position

an oil drain pan under the differential.

2. Remove all original differential cover bolts

and set aside. Using a medium hammer

hit the side of the diff cover to break the seal.

If necessary, use a chisel or pry bar to break

the seal and separate the cover from the

housing. Be careful not to gall the sealing

surface of the housing.

3. Let the gear oil drain from the housing into

a pan (please recycle or dispose of your

used oil properly). Clean out the inside of

the housing with brake cleaner and wipe

dry. Use a wire wheel, gasket scraper or

razor blade to clean ALL old gasket material

and debris off the sealing surface of the

differential housing.

4. You can use either a gasket or silicon sealant

on the differential (we provide silicon as it is

our preferred choice) . It is usually easiest

to put the silicon on the housing first. If you

choose to use a gasket it is usually easier to

install the gasket onto the Bombshell.

5. Place the Bombshell onto the axle housing

with the gasket (if used) and bolt holes

properly aligned. Install the new Grade 8

hex head cap screws and lock washers in

all mounting locations. Use the wrench to

tighten the bolts in an alternating pattern until

even factory torque spec is achieved.

6. Refill your differential with gear oil according

to your owners manual. IMPORTANT: The

fill hole should NOT be considered the full

line. In some cases filling to the fill hole

will result in an over-full situation, and

may result in blowing fluid out through the

breather. Consult your owner’s manual or

manufacturer’s documentation to determine

the appropriate volume of fluid to use.

7. Install fill plug using teflon tape or pipe thread

sealer on the threads.

8. Check for proper clearance with all chassis

components by cycling suspension/steering

in all directions.

9. Periodically re-torque cover bolts (make it

a normal part of your routine maintenance

regimen).