4 rear drive hubs, 1 rear drive hub service, Wheels and tires – JLG 534D-10 User Manual

Page 93: Rear drive hubs, Rear drive hub service

5.9

534D-9, 534D-10 & 544D

Axles, Wheels and Tires

5.4

REAR DRIVE HUBS

5.4.1

Rear Drive Hub Service

Detailed drive hub service instructions (covering repair,

disassembly, reassembly and adjustment) are provided

in the MH439-0695 Auburn Power Wheel Service Manual

(JLG P/N 31200374).

Note: The removal, disassembly and installation of the

rear drive hub applies for either side.

a. Rear Drive Hub Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the travel select lever in the (N) NEUTRAL

position, engage the parking brake, straighten all

wheels and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel, stating that the machine

should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Remove the battery negative (-) cable from the

battery negative (-) terminal.

5. Block the front and rear of both tires on the front

axle.

6. Raise the machine using a suitable jack or hoist.

Place suitable supports under both sides of the

frame and lower the machine onto the supports.

Ensure that the machine will remain in place during

hub removal.

7. Mark and remove the wheel and tire assembly from

the hub that is being removed. Refer to Section

5.6.1, “Removing Wheel and Tire Assembly from

Machine.”

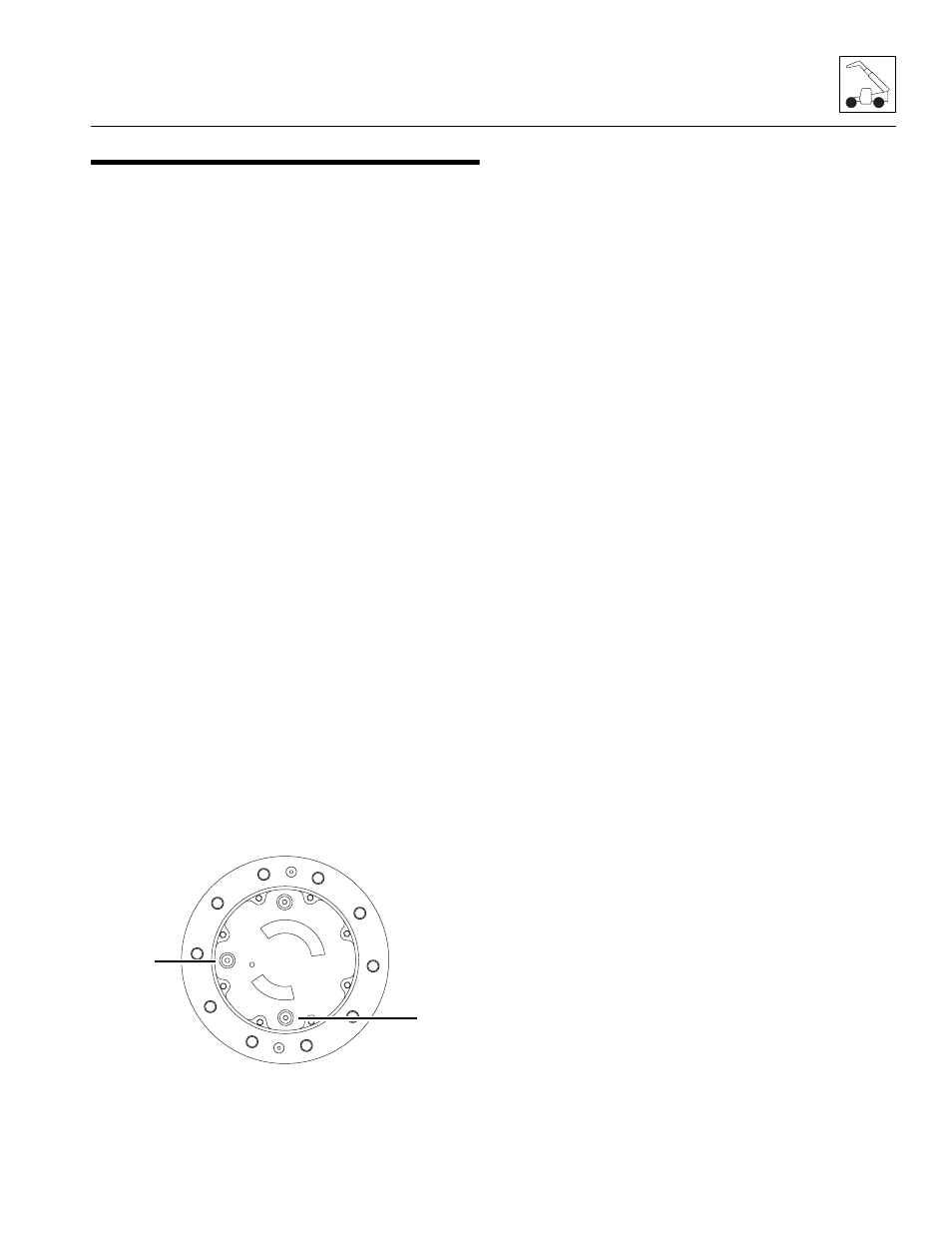

8. Remove the drain plug (1) and allow the wheel hub

oil to drain into the receptacle. Transfer the used axle

oil into a suitable covered container, and label the

container as “Used Oil.” Dispose of used oil at an

approved recycling facility.

9. Refer to Section 8.7.2, “Rear Drive Motors,” for drive

motor removal.

10. Support the drive hub using a suitable jack, hoist or

overhead crane and sling.

11. Remove the eight bolts holding the drive hub to the

steering knuckle.

Note: Mark the location of the two 12 point hub

mounting bolts.

12. Set the drive hub on a suitable support or table.

b. Rear Drive Hub Installation

1. Before proceeding, ensure that the machine will

remain in place during drive hub installation. Block

the front and rear of both tires on the front axle.

2. Using a suitable jack, hoist or overhead crane and

sling, balance the hub and prevent it from tipping,

turning or falling while positioning it at the steering

knuckle. Keep the hub supported and balanced on

the jack, hoist or overhead crane and sling

throughout the installation procedure.

3. Position the hub at the steering knuckle and align the

hub housing with the holes in the knuckle.

4. Install the eight bolts and torque to

280 lb-ft +/- 10 lb-ft (380 Nm +/- 13,5 Nm).

5. Refer to Section 8.7.2, “Rear Drive Motors,” for drive

motor installation.

6. Refer to Section 5.6.2, “Installing Wheel and Tire

7. Align the fill mark (2) on the hub and fill to the proper

level with Mobilfluid 424

®

(ISO 46).

8. Connect the battery negative (-) cable from the

battery negative (-) terminal.

9. Close and secure the engine cover.

10. Remove the blocks from the front and rear of both

tires on the front axle.

11. Start the machine and check proper operation.

Check for fluid leaks. Check the hydraulic fluid level

in the tank and add fluid as required.

MX0650

QU

E

B

H

R

R

O

T

U

1

2