13 engine drive plate/coupling, 1 drive plate/coupling removal, 2 drive plate/coupling installation – JLG 534D-10 User Manual

Page 122: Section 8, Engine drive plate/coupling, Drive plate/coupling removal, Drive plate/coupling installation

Engine

7.14

534D-9, 534D-10 & 544D

22. If installing new hydraulic oil filters, fill with Mobilfluid

424

®

Tractor Hydraulic Fluid (ISO 46) before

installing on the filter head.

23. Check that all hydraulic system, electrical system,

cooling system, fuel system, and exhaust system

connections are correct and connected tightly

Note: Have an assistant stand by with a Class B fire

extinguisher. Start and idle the engine.

24. Run engine to normal operating temperature then shut

off the engine. While the engine is cooling, check for

leaks.

25. Allow the engine to cool. Check the radiator coolant

level, and top off with a 50/50 mixture of ethylene

glycol and water. Replace the radiator cap.

26. Check for leaks from the engine, main hydraulic pump

and lines, drive pump, hydraulic reservoir and fuel

tank. Check the levels of all fluids and lubricants. Fill

as required.

Note: During the full throttle check:

• DO NOT operate any hydraulic function.

• DO NOT steer or apply any pressure to the steer-

ing wheel.

• Keep the transmission in NEUTRAL (N).

27. Purge the hydraulic system of air by operating all

boom functions through their entire range of motion

several times. Check the hydraulic oil level.

28. Check for proper operation of all components.

29. Turn the engine OFF.

7.13

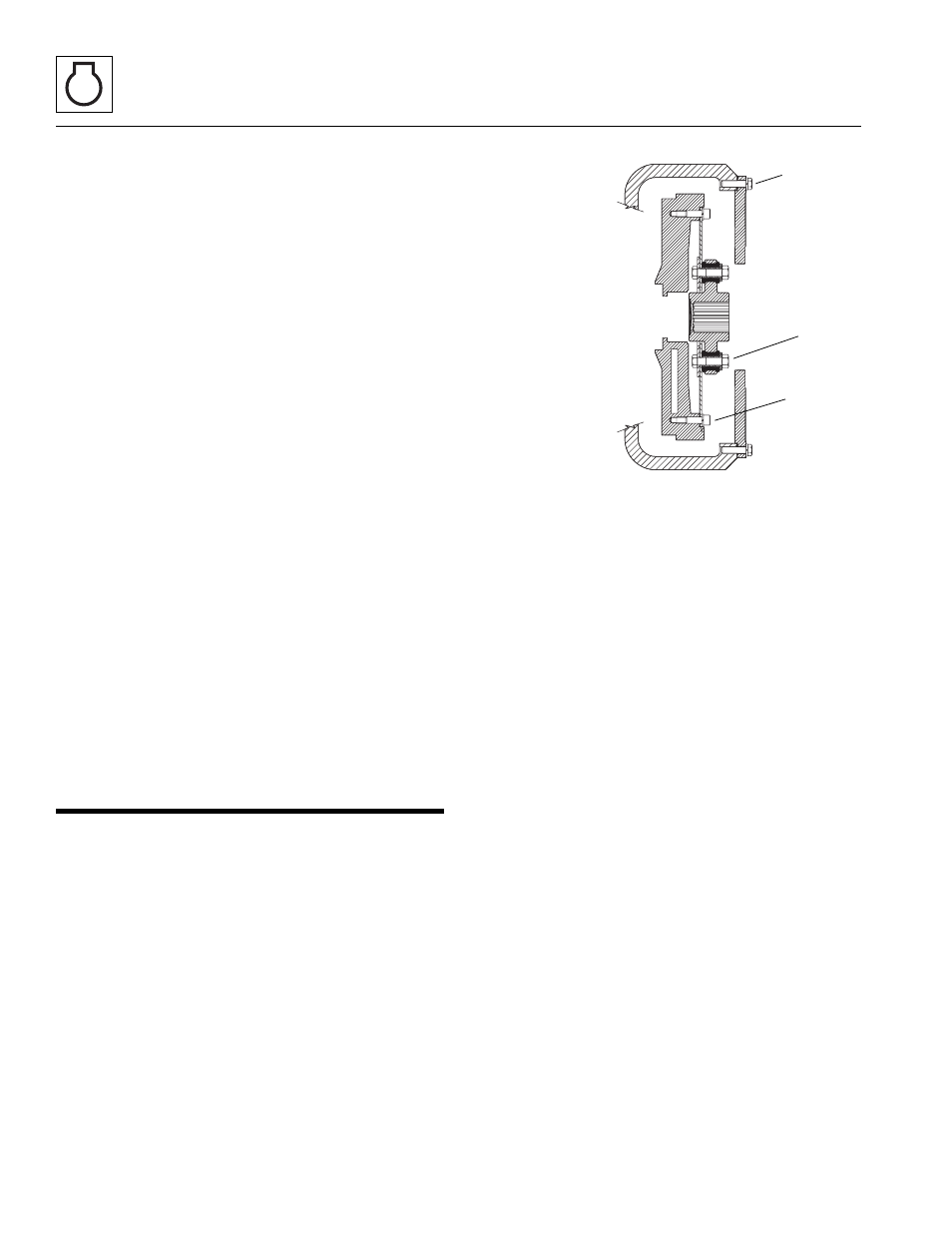

ENGINE DRIVE PLATE/COUPLING

7.13.1

Drive Plate/Coupling Removal

1. Level the machine, ground the attachment, place the

travel select lever in NEUTRAL (N), engage the

parking brake and shut off the engine.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

Note: In order to remove the engine drive plates, the

engine and transmission must be separated.

3. Refer to Section 6.5.1, “Drive Pump Removal,” or

Section 7.12.1, “Engine Removal.”

4. Loosen and remove the bolts (1) holding the pump

mounting plate to the engine bell housing. Remove

the mounting plate.

5. Remove the bolts (2) holding the drive plate to the

flywheel.

6. With the drive plates removed, loosen and remove

the bolts (3) holding the coupling to the drive plate.

7. Replace the drive plate and/or the coupler if

damaged.

7.13.2

Drive Plate/Coupling Installation

1. Install the new coupler (3) on the drive plate and

torque the bolts with lock washers to 40-45 lb-ft

(54-61 Nm).

2. Mount the drive plate/coupler assembly (2) to the

flywheel, install the bolts and torque to 40-45 lb-ft

(54-61 Nm).

3. Install the pump mounting plate (1) to the engine bell

housing and torque the bolts to 40-45 lb-ft

(54-61 Nm).

4. Refer to Section 6.5.3, “Drive Pump Installation,”or

Section 7.12.3, “Engine Installation,” for the

remainder of the installation.

MX1000

1

2

3