11 gauges, 1 analog gauges, 12 dash switches – JLG 534D-10 User Manual

Page 163: 1 ignition key switch, Gauges, Analog gauges, Dash switches, Ignition key switch

9.15

534D-9, 534D-10 & 544D

Electrical System

3. If the fuel level indicator needle does not move after

the ignition key switch is turned to the RUN position,

use a test lamp to determine whether current is

flowing from the ignition switch to the fuel level

sender.

4. If the fuel level indicator does not move and a faulty

or defective fuel level sender in the fuel tank has

been ruled out, and in addition, wiring and

connectors have been checked and ruled out, the

fuel level indicator is defective and must be replaced.

5. Check that the ignition terminal has current and that

the fuse in the fuse panel is not blown.

6. Check for broken, shorted, frayed, disconnected or

damaged wiring between the fuel level indicator

wiring at the cab, fuse and relay panel, ignition key

switch, and from the fuel level sender on the fuel

tank through the wiring in the cab.

7. Check the fuel level sender. A defective fuel level

sender in the fuel tank may also prevent the fuel

level indicator from moving. Refer to Section 9.5,

“Electrical System Schematics,” for further

information.

9.11

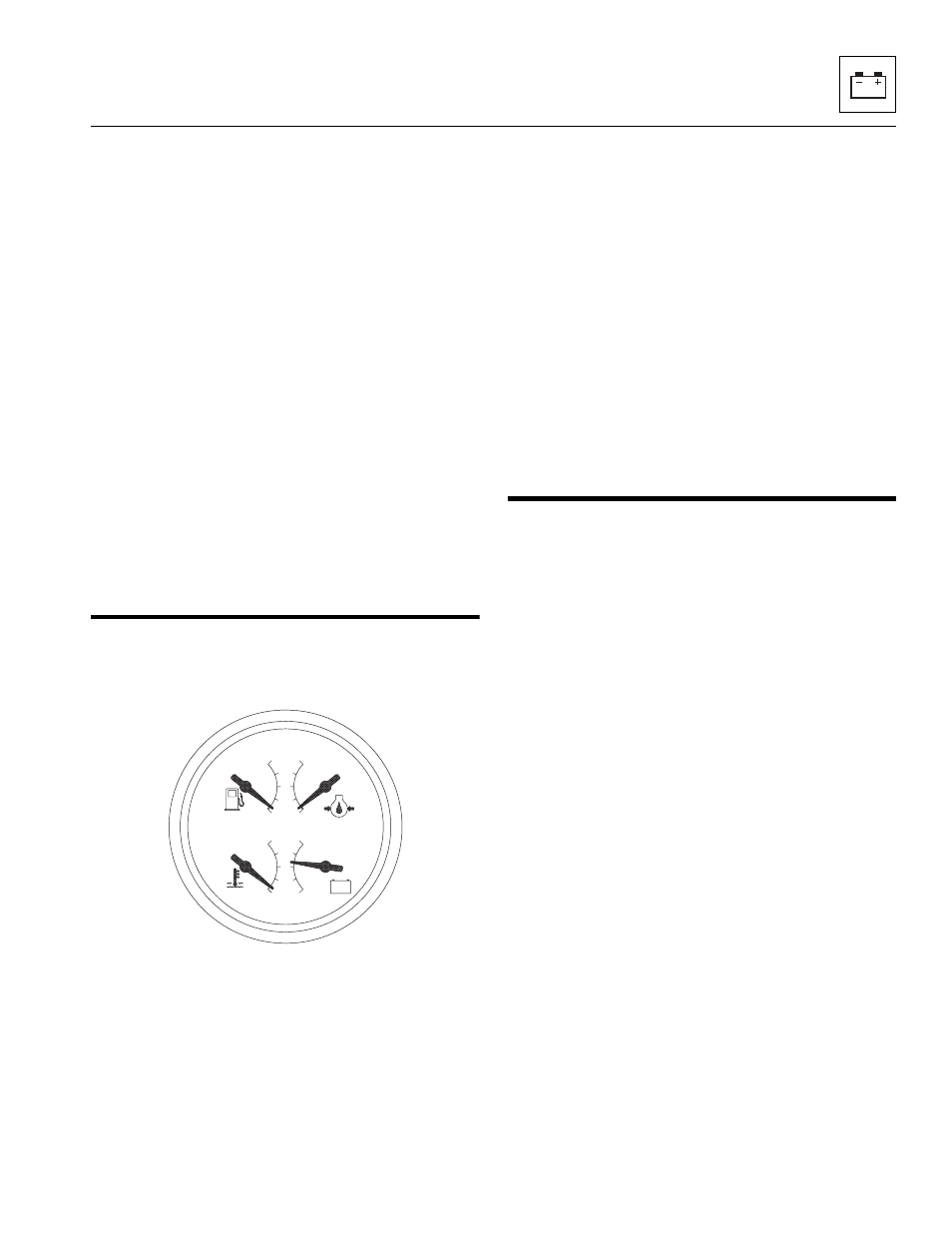

GAUGES

9.11.1

Analog Gauges

The machine is equipped with an analog fuel level, oil

pressure, water temperature and battery voltage gauge.

a. Removal

1. Remove the battery negative (-) cable at the negative

battery (-) terminal.

2. Remove the four bolts holding the gauge panel,

unplug connectors from the harness on the backside

of the gauge panel and remove the panel from the

dash.

b. Disassembly

DO NOT disassemble the gauge. The gauge is not

serviceable. Replace the gauge if found to be defective.

c. Installation and Testing

1. Install the gauge in the dash. Install the gauge

bracket, lock washers and nuts. Connect the wire

connections.

2. Connect the battery negative (-) cable at the negative

battery (-) terminal.

3. Turn the ignition to the ON position to check the fuel

level. If gauge is not reading properly refer to Section

9.10.4, “Fuel Level Sender.”

4. Start the machine and allow the engine to warm to

check the engine water temperature.

9.12

DASH SWITCHES

Note: For information on the front windshield wiper, rear

window wiper and washer systems, refer to Section

9.8.1, “Windshield Washer Reservoir and Pump.”

9.12.1

Ignition Key Switch

a. Ignition Switch Removal

1. Remove the battery negative (-) cable at the negative

battery (-) terminal.

2. Remove lower access panel.

3. Remove the hex nut securing the ignition key switch

to the dash.

4. Reach up and under the dash to work the ignition

switch and wiring out of the mounting hole.

5. Disconnect the ignition switch connectors from the

cab harness connectors, and remove the switch

from the machine.

b. Disassembly

DO NOT disassemble the ignition switch. Replace a

defective switch with a new part.

c. Inspection and Replacement

To determine the proper operation of the ignition key

switch, using the following charts, test the wires on the

back of the switch for continuity with an ohmmeter.

Test the ignition key switch for continuity, by checking

from the ignition (Red - Battery) wire to each of the

following wires in each switch position. Continuity (X)

should be present as indicated in the following chart:

MX0740

240

100

F

E

100

0

16

10

TEMP

FUEL

OIL

VOLTS

-

+