4 cab removal, Section 5, Cab removal – JLG 534D-10 User Manual

Page 82: Warning

Cab and Covers

4.8

534D-9, 534D-10 & 544D

b. Heater Assembly Installation

1. Position the heater assembly to its original orientation

in the cab. Secure with the previous hardware.

2. Connect the previously labeled electrical

connections.

3. Connect the previously labeled heater hoses to their

appropriate locations.

4. Install the belly pan, rear cover and access cover.

5. Open both coolant valves on the engine. Open the

radiator cap and check the coolant level. Fill if

necessary. The cooling system capacity is listed in

Section 2.4, “Fluid and Lubricant Capacities.”

6. Connect the battery negative (-) cable to the battery

negative (-) terminal.

Note: When the engine is initially started, run it briefly at

low idle and check the machine for any visual sign of

fluid leakage. STOP the engine immediately if any

leakage is noted, and make any necessary repairs

before continuing.

7. Wait for the engine to cool and check the coolant

level. Add coolant as required to bring the coolant to

the proper level.

4.4

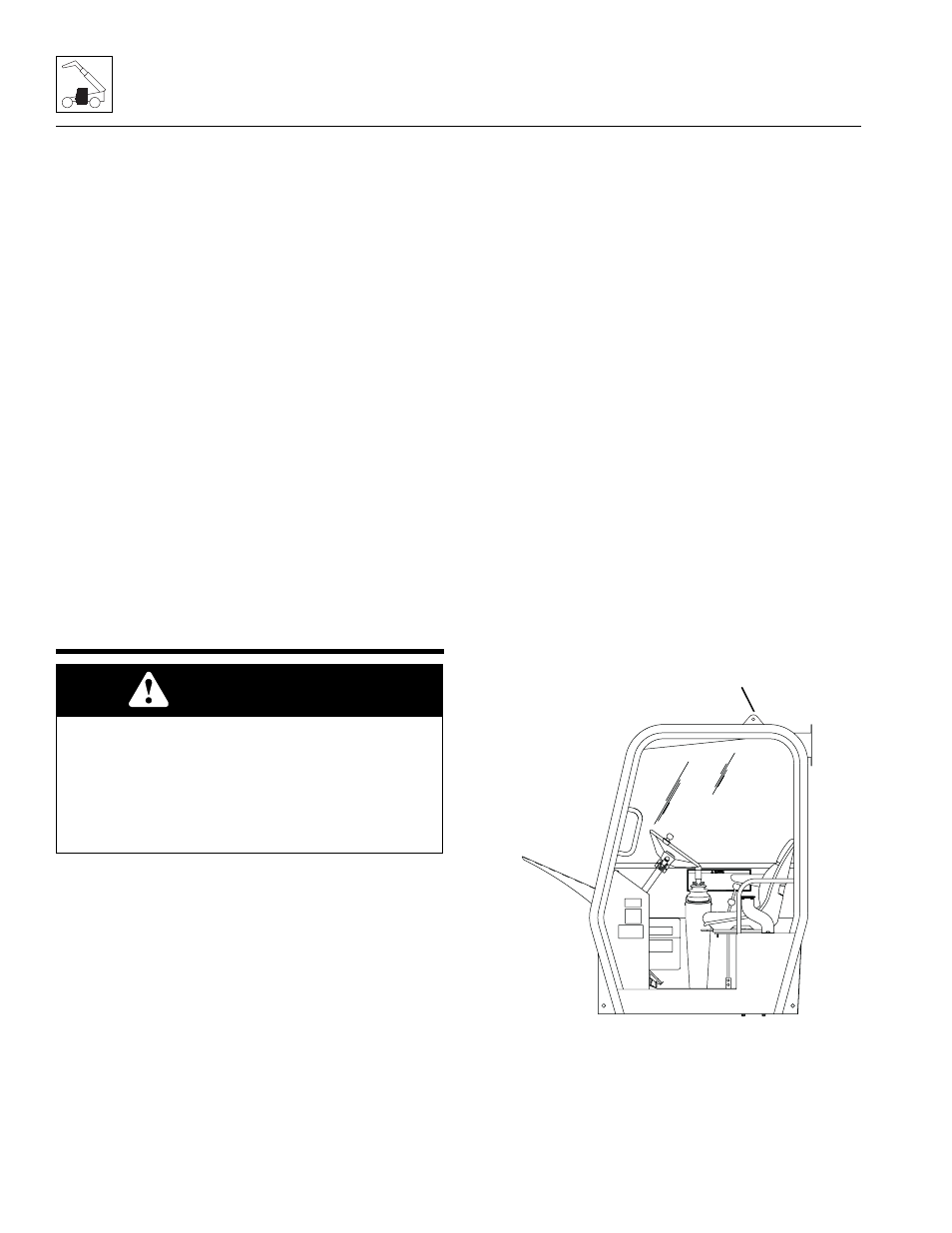

CAB REMOVAL

Inspect the cab, its welds and mounts. If modification,

damage, a cracked weld and/or fatigued metal is

discovered, replace the cab. Contact the JLG distributor or

the JLG Service Department with any questions about

the suitability or condition of a cab.

Note: Remove and label cab components as needed

before removing the cab from the machine. Label,

disconnect and cap hydraulic hoses. Transfer cab parts

to the replacement cab after the replacement cab is

securely mounted on the machine.

1. Park the machine on a firm, level surface. Allow

sufficient overhead and side clearance for cab

removal. Level the machine, ground the attachment,

place the travel select lever in the (N) NEUTRAL

position, engage the parking brake and shut the

engine OFF.

2. Open the engine cover. Allow the system fluids to

cool.

3. Disconnect the battery negative (-) cable at the

battery negative (-) terminal.

4. Shut both coolant valves located on the engine.

5. Plug and label both coolant hoses.

6. Remove the air cleaner tubing from the side of the

cab. Cover the intake opening on the engine to

prevent dirt or debris from entering the engine.

7. Disconnect the wiring harness between the cab and

frame.

Note: Record the location, and label all hoses to ensure

correct installation.

8. Working under the cab, label, disconnect all

hydraulic hoses. Cap all fittings and openings to

keep dirt & debris from entering the hydraulic

system.

9. Disconnect the throttle electrical cable from under

the cab.

10. Install eyebolts and route a sling with a suitable

lifting capacity.

11. Remove the four cab-to-frame bolts, flat washers and

nuts.

WARNING

The protection offered by this ROPS/FOPS will be

impaired if subjected to any modification or structural

damage. Any modification to this machine must be

approved by JLG to assure compliance with ROPS/

FOPS certification for this cab/machine configuration.

If damaged, the CAB CANNOT BE REPAIRED. It

must be REPLACED.

MX0840

Sling Routing