2 drive pump inspection and internal repair, 3 drive pump installation, Drive pump inspection and internal repair – JLG 534D-10 User Manual

Page 102: Drive pump installation

Hydrostatic Drive Pump

6.4

534D-9, 534D-10 & 544D

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel, stating that the machine

should not be operated.

3. Open the engine cover. Allow the system fluids to cool.

4. Remove rear cover to allow easier access to the

drive pump.

5. Remove belly pan from under engine.

6. Drain the hydraulic oil reservoir. Refer to Section 8.5,

7. Remove the battery negative (-) cable from the

battery negative (-) terminal.

8. Thoroughly clean the drive pump and surrounding

area, including all hoses and fittings, before

proceeding.

9. Place a suitable receptacle under the drive pump.

10. Label and disconnect both shift solenoid wiring

harness connectors.

11. Label, disconnect and cap the all hydraulic hoses

and tubes attached to the drive pump. Cap all fittings

and openings to keep dirt & debris from entering the

hydraulic system.

12. Wipe up any spilled hydraulic oil.

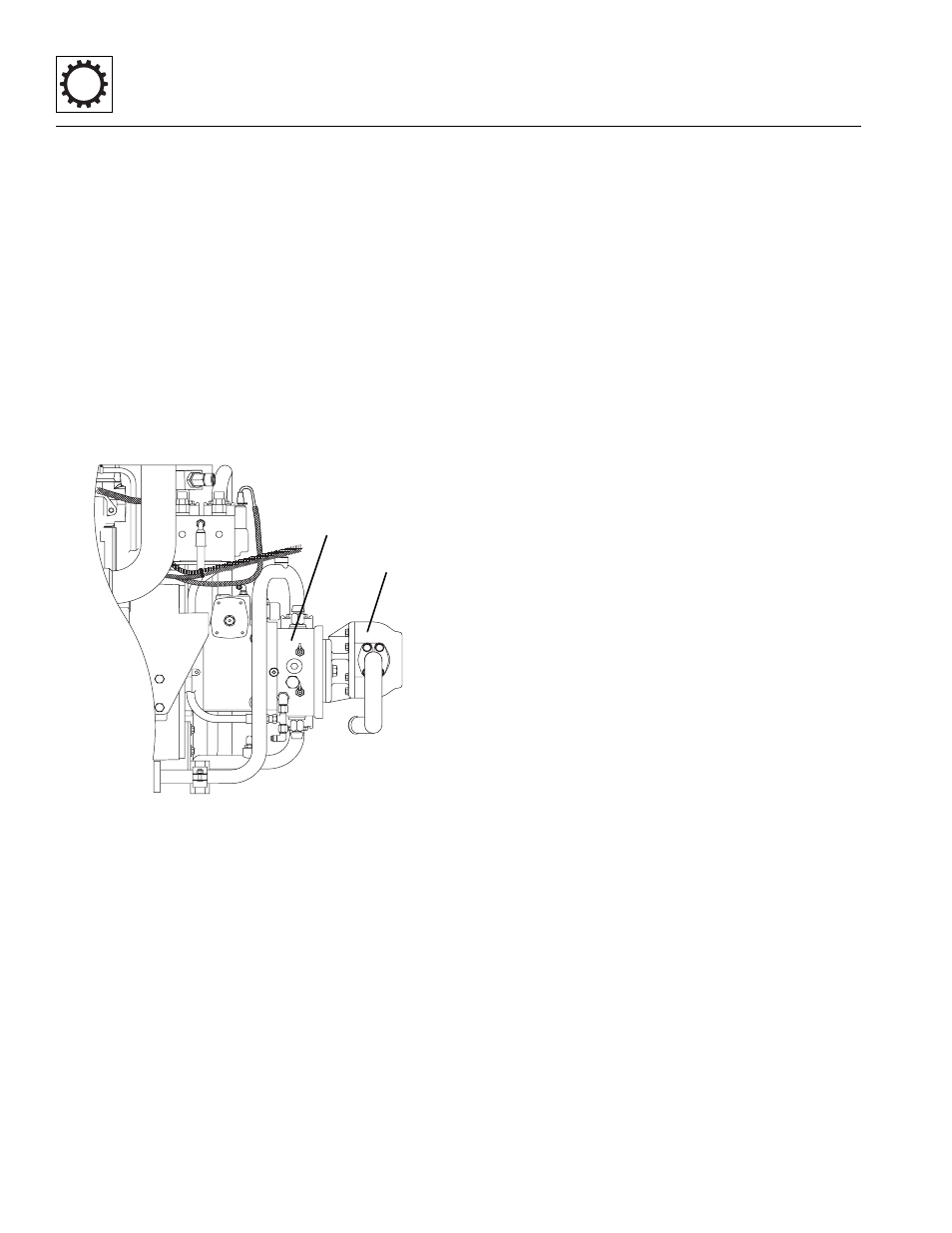

13. Loosen and remove both bolts holding the

implement pump (1) to the drive pump (2).

14. Pull the implement pump away from the drive pump.

15. Connect a lifting strap or chain to the top of the drive

pump, and to a suitable hoist or overhead crane.

Operate the hoist or crane to remove slack from the

chain, but DO NOT raise the drive pump at this time.

16. Loosen and remove the two bolts holding the drive

pump to the engine bellhousing.

17. Carefully remove the drive pump from the machine.

Avoid causing damage to the drive pump or

surrounding parts.

18. Lift the drive pump clear of the machine and lower it

onto suitable supports or secure it to a stand built

especially for drive pump or engine service. Secure

the drive pump so that it will not move or fall.

6.5.2

Drive Pump Inspection and Internal

Repair

Note: Contact the JLG Service Department if internal

drive pump repair is required.

6.5.3

Drive Pump Installation

1. Use a hoist or overhead crane and sling attached to

the drive pump. Raise and position the drive pump

within the chassis.

2. Align the input shaft, align the drive pump bolt holes

with the two holes in the bell housing. Install the two

bolts and washers and torque to 240 lb-ft (240 Nm).

3. Remove the hoist or overhead crane and sling.

4. Align the input shaft, align the bolt holes of the

implement pump to the drive pump. Install the two

bolts and washers and torque to 160 lb-ft (217 Nm).

5. Connect the drive pump shift solenoid wiring

harness connectors.

6. Secure the wiring harness to the drive pump

housing.

7. Uncap and connect all the hydraulic hoses and

tubes.

8. Install the rear cover and belly pan.

9. Refill the hydraulic oil reservoir. Refer to Section 8.5,

10. Connect the (-) negative battery cable.

11. Start engine and check for any hydraulic leaks.

12. Close and secure the engine cover.

MX0870

1

2