4 steering orbitrol valve, 9 hydraulic cylinders, 1 general cylinder instructions – JLG 534D-10 User Manual

Page 145: 2 cylinder disassembly, Lectrical system, Steering orbitrol valve, Hydraulic cylinders, General cylinder instructions, Warning, Notice

8.21

534D-9, 534D-10 & 544D

Hydraulic System

8.8.4

Steering Orbitrol Valve

The steering orbitrol valve (4) is located at the base of the

steering wheel shaft. The valve is not serviceable and

must be replaced in its entirety if defective. For detailed

information refer to Section 4.3.1, “Steering Column and

Orbitrol Valve.”

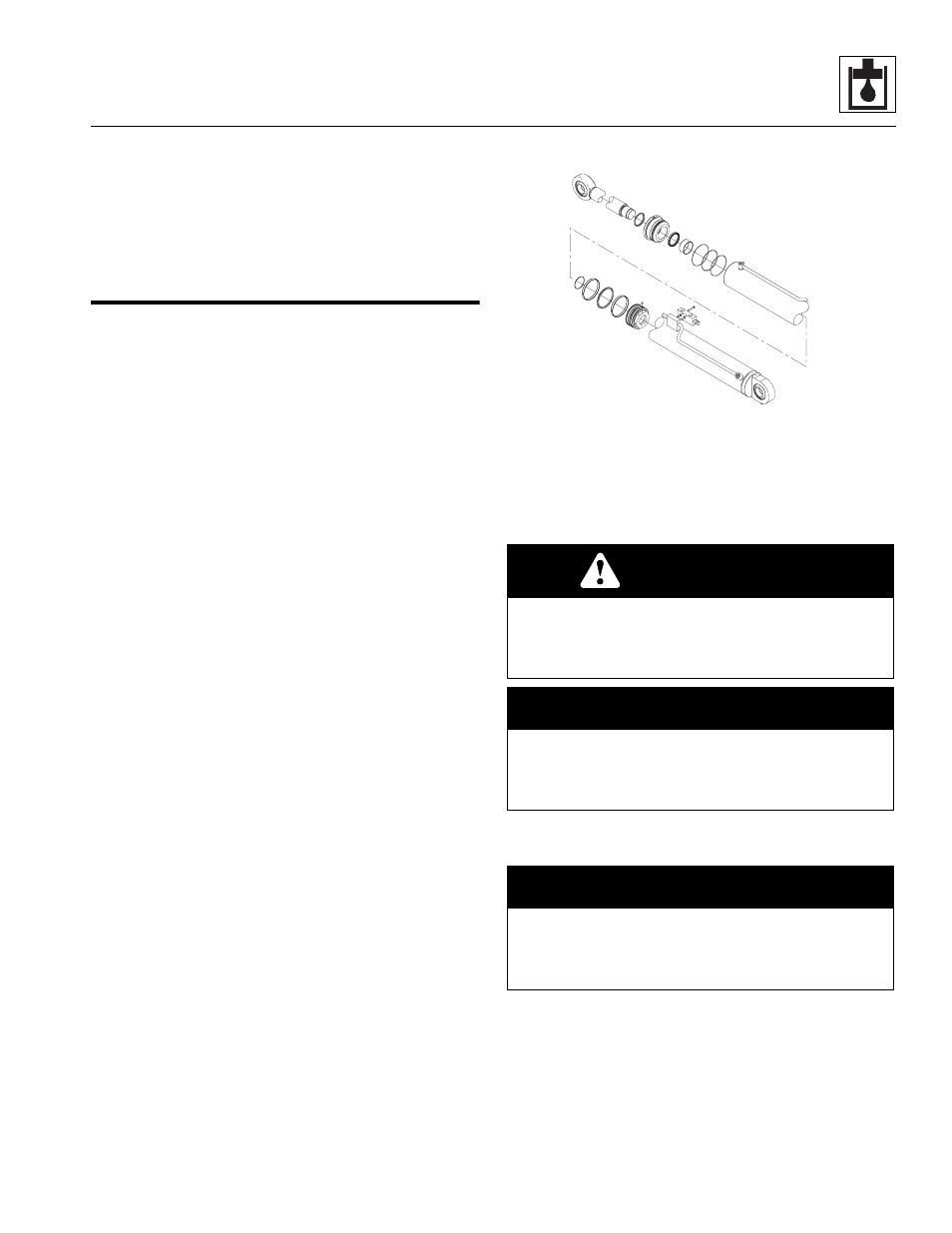

8.9

HYDRAULIC CYLINDERS

8.9.1

General Cylinder Instructions

a. Cylinder Removal

1. Remove any attachment from the machine. Park the

machine on a firm level surface and fully retract the

boom. Allow sufficient work space around the

hydraulic cylinder being removed. Support the boom

if the lift/lower cylinder is being removed. Place the

travel select lever in (N) NEUTRAL, engage the park

brake, shut the engine OFF and chock wheels.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Label, disconnect and cap or plug hydraulic hoses in

relation to the cylinder. Cap all fittings and openings

to keep dirt and debris from entering the hydraulic

system.

5. Attach a suitable sling to an appropriate lifting device

and to the cylinder. Make sure the device used can

actually support the cylinder.

6. Remove the lock bolt and/or any retaining clips

securing the cylinder pins. Remove the cylinder pins.

7. Remove the cylinder.

8. Wipe up any hydraulic fluid spillage in, on, near and

around the machine, work area and tools.

8.9.2

Cylinder Disassembly

1. Clean the cylinder with a suitable cleaner before

disassembly. Remove all dirt, debris and grease

from the cylinder.

2. Clamp the barrel end of the cylinder in a soft-jawed

vise or other acceptable holding equipment if

possible.

3. If applicable, remove the counterbalance valve from

the side of the cylinder barrel.

4. Extend the rod as required to allow access to the

base of the cylinder.

WARNING

Significant pressure may be trapped inside the cylinder.

Exercise caution when removing a counterbalance valve

or a pilot-operated check valve from a cylinder. Escaping

hydraulic fluid under pressure could penetrate the skin.

NOTICE

Avoid using excessive force when clamping the

cylinder in a vise. Apply only enough force to hold the

cylinder securely. Excessive force can damage the

cylinder tube.

NOTICE

DO NOT tamper with or attempt to adjust the

counterbalance valve cartridge. If adjustment or

replacement is necessary, replace the

counterbalance valve with a new part.

MZ0400