7 drive motors, 1 front drive motor, Hydraulic cylinders – JLG 534D-10 User Manual

Page 138: Drive motors, Front drive motor

Hydraulic System

8.14

534D-9, 534D-10 & 544D

8. Label, disconnect and cap the hydraulic hoses

attached to the pump.

9. Remove the two bolts and two lockwashers (1)

securing the pump to the engine. Remove the o-ring

located between the engine and the pump. Wipe up

any hydraulic oil spillage.

Note: DO NOT disassemble the operating pump. The

pump is pre-set from the manufacturer. Any adjustments

or repairs performed by anyone other than an authorized

dealer could void the warranty.

b. Pump Installation

1. Place the pump and a new, oiled o-ring into position

on the engine. Align the pump shaft with the internal

engine gear, so that the machined teeth mesh

together.

2. Align the bolt holes with the pump mount holes.

Secure the pump to the transmission with the two

bolts and washers.

3. Uncap and connect the previously labeled hydraulic

hoses to their appropriate locations.

4. Fill the hydraulic reservoir. Refer to Section 8.5.2,

“Hydraulic Oil Reservoir Filling.”

5. Prime the pump by filling the case drain port with fresh,

filtered hydraulic oil from a clean container before

installing the case drain connector and hose.

6. Check all routing of hoses and tubing for sharp

bends or interference with any rotating members. All

tube and hose clamps must be tight.

7. Start the engine and run at approximately one-third

to one-half throttle for about one minute without

moving the machine or operating any hydraulic

functions.

8. Inspect for leaks and check all fluid levels. The

hydraulic reservoir oil level must be to the middle of

the sight gauge.

c. Pump Test

Refer to Section 8.3.1, “Pressure Checks and

Adjustments.”

1. Check the system functions.

8.7

DRIVE MOTORS

8.7.1

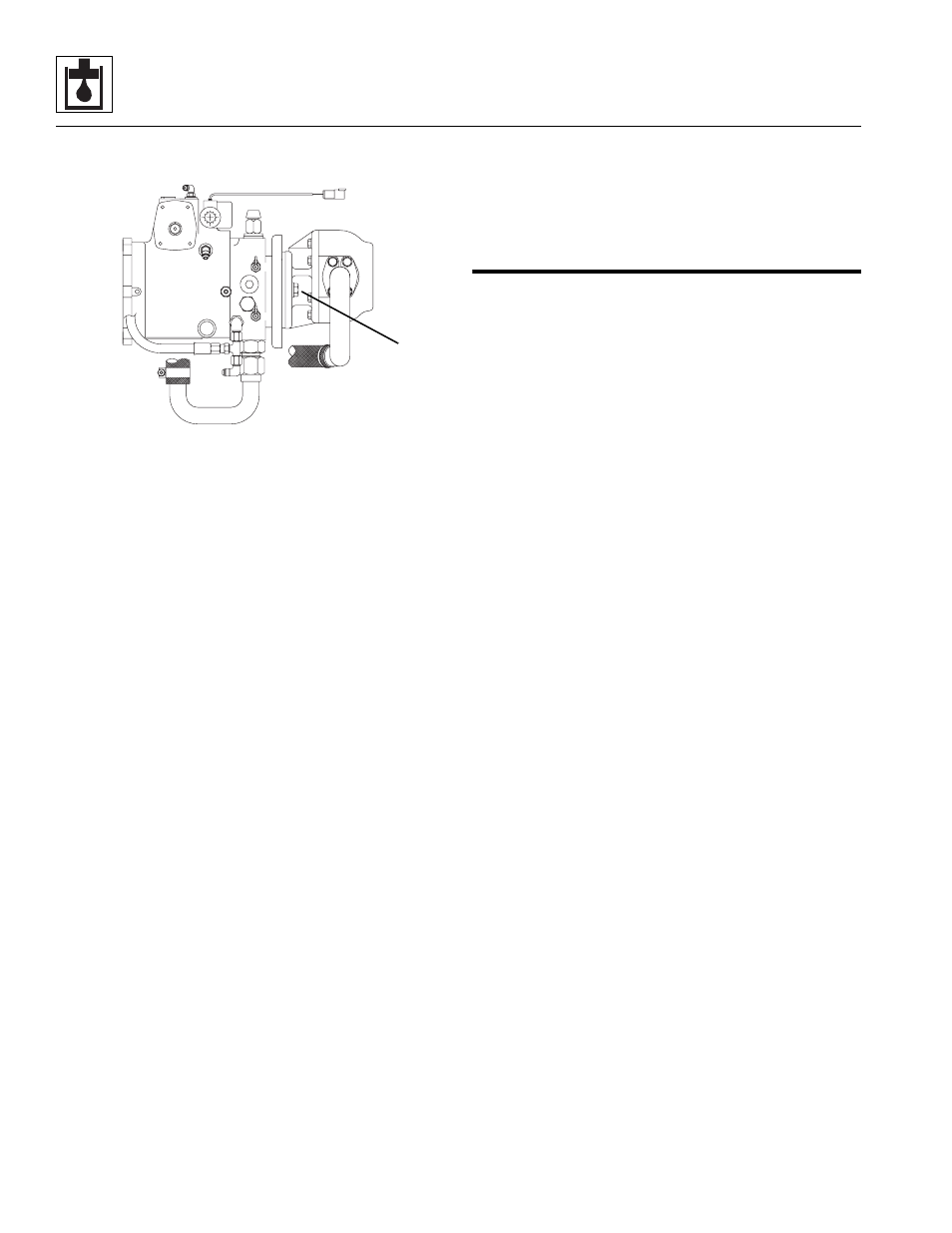

Front Drive Motor

The front drive motor is mounted to the carrier of the front

drive axle and powers the machine in 2WD and 4WD.

a. Front Drive Motor Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, raise the boom to

access drive motor, place the transmission control

lever in (N) NEUTRAL, engage the park brake and

shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Open the engine cover and the hydraulic oil

reservoir/fuel tank cover. Allow the system fluids to

cool.

4. Remove the deck cover and disconnect the battery

negative (-) cable from the battery negative (-)

terminal.

5. With the engine OFF, relieve any trapped pressure in

the hydraulic system.

6. Thoroughly clean the drive motor and surrounding

area, including all hoses and fittings, before

proceeding.

7. Place a suitable container to catch hydraulic fluid

drainage beneath the frame.

Note: Cap all hoses as you remove them to prevent

unnecessary fluid spillage.

8. Label, disconnect and cap all the hydraulic hoses

attached to the drive motor. Cap all fittings and

openings to prevent dirt and debris from entering the

hydraulic system.

9. Wipe up any hydraulic fluid spillage in, on, near and

around the machine and the work area.

10. Loosen and remove the four bolts holding the drive

motor to the carrier housing.

11. Pull the drive motor back from the axle carrier and

place on a suitable support or table.

Ma

Ps

Mb

S

T

2

G

MX1150

1