Burnham Independence IN10 User Manual

Page 59

59

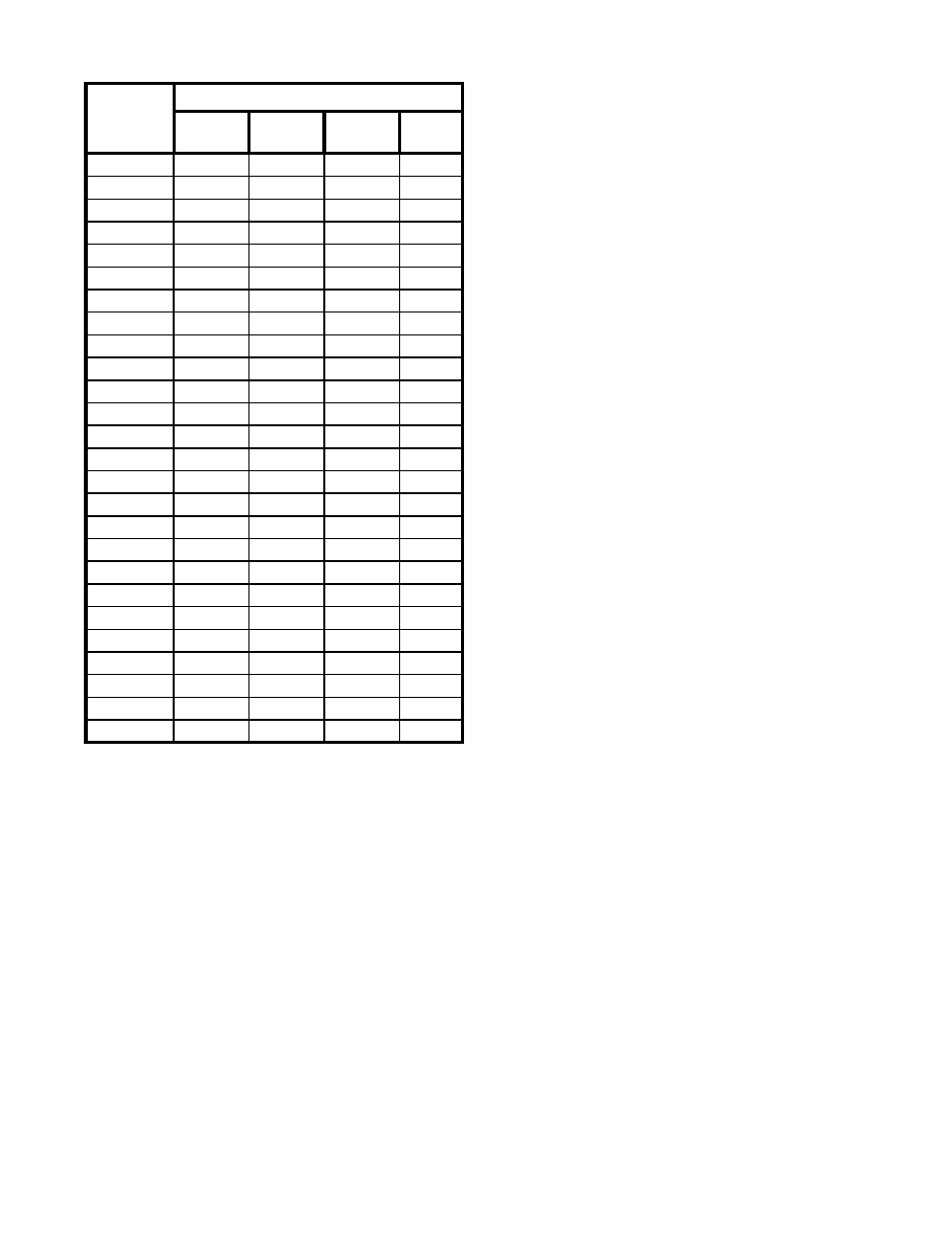

Table 10: Input Rate

L.

Adjust gas input rate to boiler. LP/Propane.

1. Set thermostat to highest setting.

2. Adjust tank regulator for gas valve inlet pressure of

13.5 inches w.c. or less.

3. Gas valve has step opening regulator which initially

opens to 1.4 or 2.5 inch w.c. and steps to full

pressure after approximately 30 seconds. Check

manifold pressure after step has occurred. Adjust gas

valve pressure regulator as necessary for 10.0 inches

w.c. (turn adjustment screw counterclockwise to

decrease manifold pressure, or clockwise to increase

manifold pressure). If 10.0 inches w.c. can not be

attained, check gas valve inlet pressure. If less than

11.0 inches w.c., contact gas supplier for assistance.

M.

Clean Heating System (Steam). A local qualified

water treatment chemical specialist is a suggested

source for recommendations regarding appropriate

chemical compounds and concentrations which are

compatible with local environmental regulations.

1. Oil from new piping connections and sediment in

existing piping must be removed from system to

prevent unsteady water line and carry-over of

entrained water into supply main.

a. Fill boiler to normal waterline.

b. Follow Lighting or Operating Instructions to

place boiler in operation. See Figure 48, 49, 50,

or 51.

c. Operate boiler with steam in entire system for

several days to bring system oil and dirt back to

boiler.

d. Drain condensate from drain valve in wet return.

Operate boiler until condensate runs clean.

2. Boil-out boiler.

a. Follow instructions TO TURN OFF GAS TO

APPLIANCE. See Figure 48, 49, 50, or 51.

b. Fill boiler to normal waterline.

c. Remove safety valve.

d. Pour recommended boil-out compound into

boiler through safety valve opening.

e. Reinstall safety valve in Tapping "E" with

spindle in vertical position. See Figures 1 and 2.

f. Follow Lighting or Operating Instructions to

place boiler in operation. See Figure 48, 49, 50,

or 51.

Check controls operation per Paragraphs F to J.

Boil water for at least 5 hours.

g. Follow instructions TO TURN OFF GAS TO

APPLIANCE. See Figure 48, 49, 50, or 51.

Drain boiler and system piping.

h. Remove drain valve. Thoroughly wash boiler

water passages with high pressure spray through

drain valve tapping.

i. Reinstall drain valve in Tapping "F". See

Figures 1 and 2.

3. Second Boil-out for Stubborn Cases. If all oil and

grease is not removed a second boilout using surface

blow-off is necessary.

a. Run 1 NPT pipe from Surface Blow-Off Tapping

"L" to open drain. Do not install shut-off valve or

other restriction. See Figure 2.

b. Fill boiler to top of gauge glass.

c. Remove safety valve.

d. Pour recommended boil-out compound into

boiler through safety valve opening.

e. Reinstall safety valve in Tapping "E" with

spindle in vertical position. See Figures 1 and 2.

f. Follow Lighting or Operating Instructions to

place boiler in operation. See Figure 48, 49, 50,

or 51. Boil water for approximately 5 hours

without producing steam.

g. Open boiler fill shut-off valve to produce steady

trickle of water from surface blow-off pipe.

Continue boil-out for several hours until surface

blow-off water runs clear.

Seconds

for One

Revolution

Size of Gas Meter Dial

One-Half

Cu. Ft.

One

Cu. Ft.

Two

Cu. Ft.

Five

Cu. Ft.

30

60

120

240

600

32

56

113

225

563

34

53

106

212

529

36

50

100

200

500

38

47

95

189

474

40

45

90

180

450

42

43

86

172

430

44

41

82

164

410

46

39

78

157

391

48

37

75

150

375

50

36

72

144

360

52

35

69

138

346

54

33

67

133

333

56

32

64

129

321

58

31

62

124

310

60

30

60

120

300

62

29

58

116

290

64

29

56

112

281

66

29

54

109

273

68

28

53

106

265

70

26

51

103

257

72

25

50

100

250

74

24

48

97

243

76

24

47

95

237

78

23

46

92

231

80

22

45

90

225