Iii. semi-pak boiler assembly warning – Burnham Independence IN10 User Manual

Page 13

1

III. Semi-Pak Boiler Assembly

WARNING

Installation of this boiler should be undertaken

only by trained and skilled personnel from a

qualified service agency.

A.

Remove Crate

1. Remove all hold down screws and brackets.

2. Slide boiler to rear of skid and carefully remove

from crate skid onto 2 inch thick piece of wood and

then onto floor. Do not bump boiler jacket against

floor.

3. Do not drop boiler at any time.

B.

Move Boiler To Permanent Position. Refer to Section

I: Pre-Installation.

C.

Identify Trim and Controls

FIRST - Determine controls ordered with boiler and

refer to appropriate section(s) following:

There are two ordering methods for trim and controls:

1. EZ–Connect Carton (either steam or water) includes

trim, controls, wiring and wiring instructions for

installation.

2. Separate Trim Carton (steam or water) and Control

Carton (steam or water). Only wiring requiring

special connections is provided. For wiring

requirements, refer to Section VIII: Electrical and

appropriate wiring diagram.

D.

Install Trim and Controls

Refer to appropriate paragraphs (following) for trim

and controls to be installed.

1. Steam Boiler with Probe Low Water Cutoff

a. Install pressure limit control into Tapping "H"

with siphon, ¾" x ¼" hex bushing, ¾" elbow and

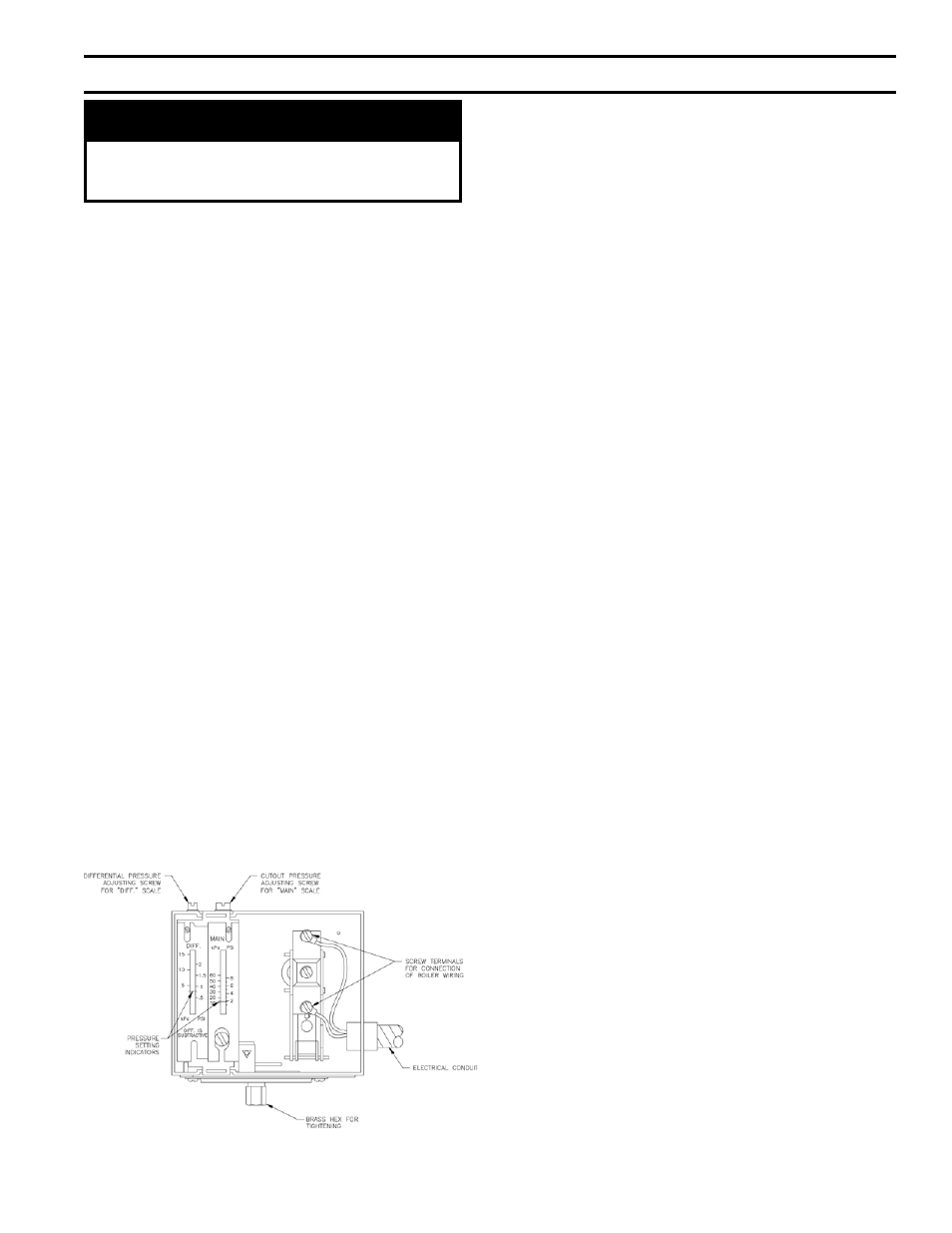

¾" x 3" nipple provided. See Figures 1 and 2.

DO NOT TWIST CONTROL. Use wrench on

hex fitting located at bottom of control. See

Figure 18.

b. The L404F pressure limit employs a snap action

switch and does not require leveling. See Figure

18.

c. Install pressure gauge into Tapping "B" (½ NPT

bushed to ¼ NPT). See Figures 1 and 2. Tighten

with wrench applied to square shank on back of

gauge. DO NOT APPLY PRESSURE ON

GAUGE CASE since this may destroy

calibration of gauge.

d. Install Low Water Cutoff Probe into Tapping "K"

(¾ NPT). HANDLE PROBE WITH CARE.

e. Attach Low Water cutoff Control to Probe by

following instructions packed with control.

f. Install gauge glass fittings into Tappings "C"

(½ NPT). See Figures 1 and 2. Lower fitting has

small drain valve.

g. Install gauge glass and protective rods in fittings.

h. Attach "Lowest Permissible Water Level" Plate

with sheet metal screws in location indicated in

Figure 9.

i. Attach "Frequent Water Addition" Label above

the "Lowest Permissible Water Level" Plate.

2. Steam Boiler with McDonnell & Miller 67 Float

Low Water Cutoff

a. Install Low Water Cutoff, see instructions packed

with control.

i. Screw brass nipples with union halves into

Tappings "C" (½ NPT). See Figure 1 and 2.

ii. Attach Gauge Glass/Low Water Cutoff

Assembly to union halves.

iii. Affix Blow-Down Card to Jacket Left Side

Panel adjacent to low water cutoff.

iv. Provide blow down discharge piping.

b. Attach street elbow siphon and pressure limit

control to low water cutoff. DO NOT TWIST

CONTROL. Use wrench on hex fitting located at

bottom of control.

c. The L404F pressure limit employs a snap action

switch and does not require leveling. See Figure

18.

d. Install pressure gauge into Tapping "H" (¾ NPT

bushed to ¼ NPT). See Figures 1 and 2. Tighten

with wrench applied to square shank on back of

gauge. DO NOT APPLY PRESSURE ON

GAUGE CASE since this may destroy

calibration of gauge.

e. Attach "Lowest Permissible Water Level" Plate

with sheet metal screws in location indicated in

Figure 9.

f. Attach "Frequent Water Addition" Label above

the "Lowest Permissible Water Level" Plate.

Figure 18: L404F Pressure Limit Control