Vi. gas piping warning, Warning – Burnham Independence IN10 User Manual

Page 22

22

VI. Gas Piping

WARNING

Failure to properly pipe gas supply to boiler may

result in improper operation and damage to the

boiler or structure. Always assure gas piping is

absolutely leak free and of the proper size and

type for the connected load.

An additional gas pressure regulator may be

needed. Consult gas supplier.

A.

Size gas Piping. Design system to provide adequate gas

supply to boiler. Consider these factors:

1. Allowable pressure drop from point of delivery to

boiler. Maximum allowable system pressure is ½

psig. Actual point of delivery pressure may be less;

contact gas supplier for additional information.

Minimum gas valve inlet pressure is indicated on

Rating Label, located on the vestibule panel.

2. Maximum gas demand. Table 2 lists boiler input

rate. Also consider existing and expected future gas

utilization equipment (i.e. water heater, cooking

equipment).

Table 2: Rated Input

For materials or conditions other than those listed

above, refer to the National Fuel Gas Code, NFPA 54/

ANSI Z223.1 and/or CAN/CSA B149.1. Installation

Codes, or size system using standard engineering

methods acceptable to authority having jurisdiction.

WARNING

Failure to use proper thread compounds on all

gas connectors may result in leaks of flammable

gas.

WARNING

Gas supply to boiler and system must be

absolutely shut off prior to installing or servicing

boiler gas piping.

B.

Connect boiler gas valve to gas supply system.

1. Use methods and materials in accordance with local

plumbing codes and requirements of gas supplier. In

absence of such requirements, follow the National

Fuel Gas Code, NFPA 54/ANSI Z223.1 and/or

CAN/CSA B149.1 Installation Codes.

2. Use thread (joint) compounds (pipe dope) resistant

to action of liquefied petroleum gas.

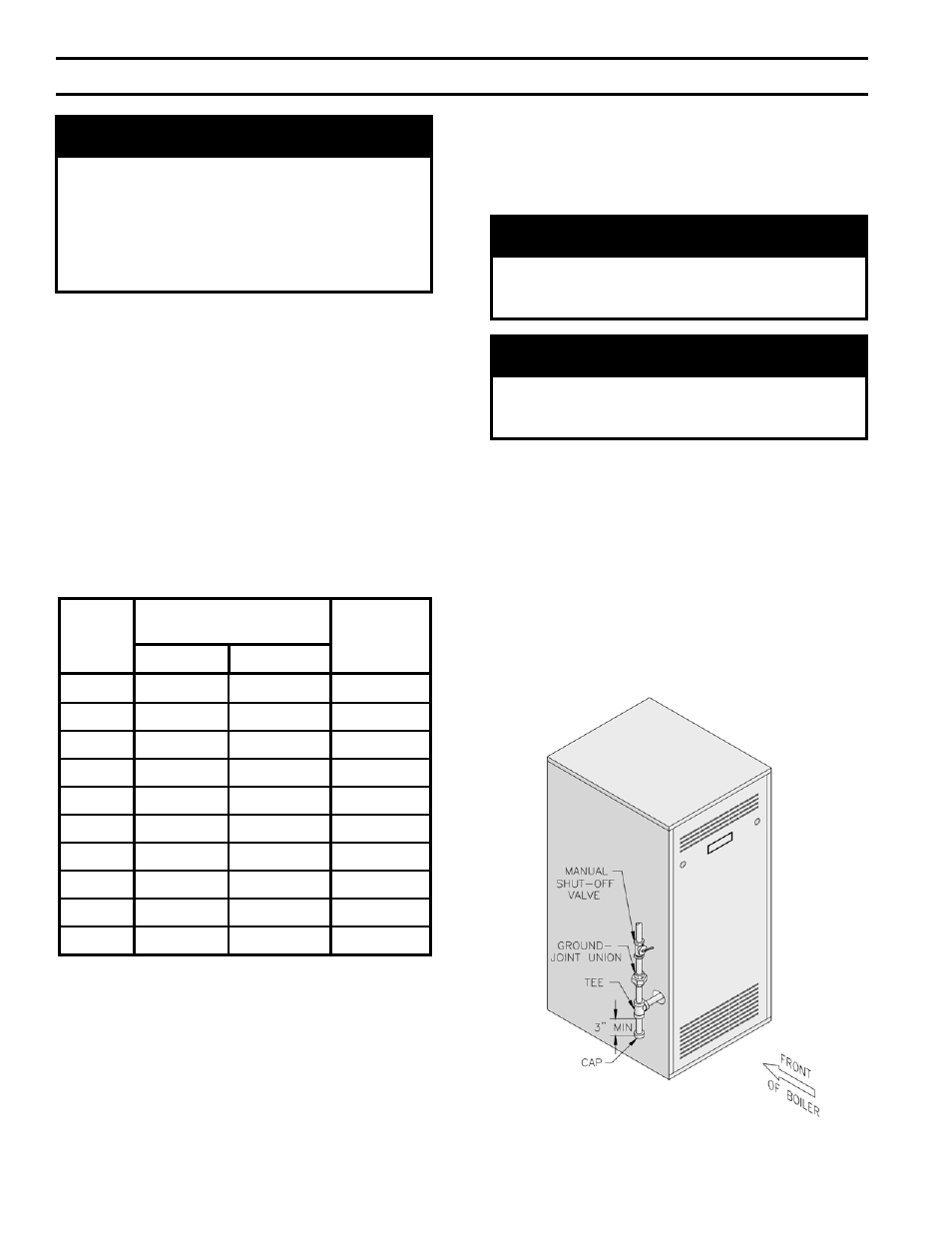

3. Install sediment trap, ground-joint union and manual

shut-off valve upstream of boiler gas valve and

outside jacket. See Figure 29.

3. Length of piping and number of fittings. Refer to

Table 3 for maximum capacity of Schedule 40 pipe.

Table 4 lists equivalent length for standard fittings.

4. Corrections for the specific gravity of natural gas

can be found in Table 5.

Figure 29: Recommended Gas Piping

Boiler

Model

Number

Rated Capacity

[cubic feet per hour]

Gas

Connection

Size

Natural

LP/Propane

IN3

62

24¾

½

IN4

105

42

½

IN5

140

56

½

IN6

175

70

½

IN7

210

84

¾

IN8

245

98

¾

IN9

280

112

¾

IN10

315

126

¾*

IN11

349

139½

¾*

IN12

385

154

1

* Gas connection size is 1" on IN10 and IN11

Continuous Ignition (Standing Pilot)