Bryant 345MAV User Manual

Page 5

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

CAUTION:

Electrostatic discharge can affect electronic

components. Take precautions during furnace installation

and servicing to protect the furnace electronic control.

Precautions will prevent electrostatic discharges from

personnel and hand tools which are held during the

procedure. These precautions will help to avoid exposing

the control to electrostatic discharge by putting the

furnace, the control, and the person at the same electro-

static potential.

1. Disconnect all power to the furnace. Multiple disconnects

may be required. DO NOT TOUCH THE CONTROL OR

ANY WIRE CONNECTED TO THE CONTROL PRIOR

TO DISCHARGING YOUR BODY’S ELECTROSTATIC

CHARGE TO GROUND.

2. Firmly touch a clean, unpainted, metal surface of the

furnace chassis which is close to the control. Tools held in

a person’s hand during grounding will be satisfactorily

discharged.

3. After touching the chassis, you may proceed to service the

control or connecting wires as long as you do nothing that

recharges your body with static electricity (for example; DO

NOT move or shuffle your feet, DO NOT touch un-

grounded objects, etc.).

4. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch metal surface again before

touching control or wires.

5. Use this procedure for installed and uninstalled (un-

grounded) furnaces.

6. Before removing a new control from its container, dis-

charge your body’s electrostatic charge to ground to protect

the control from damage. If the control is to be installed in

a furnace, follow items 1 through 5 before bringing the

control or yourself into contact with the furnace. Put all

used AND new controls into containers before touching

ungrounded objects.

7. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

INTRODUCTION

The model 345MAV 4-way multipoise, Gas-Fired, Category IV,

condensing furnaces are available in model sizes ranging in gas

input rates of 40,000 to 120,000 Btuh.

For accessory installation details, refer to applicable installation

literature.

APPLICATIONS

CAUTION:

Local codes may require a drain pan under

entire furnace and condensate trap when a condensing

furnace is used in an attic application or over a finished

ceiling. Failure to follow this caution will result in minor

property damage.

I.

GENERAL

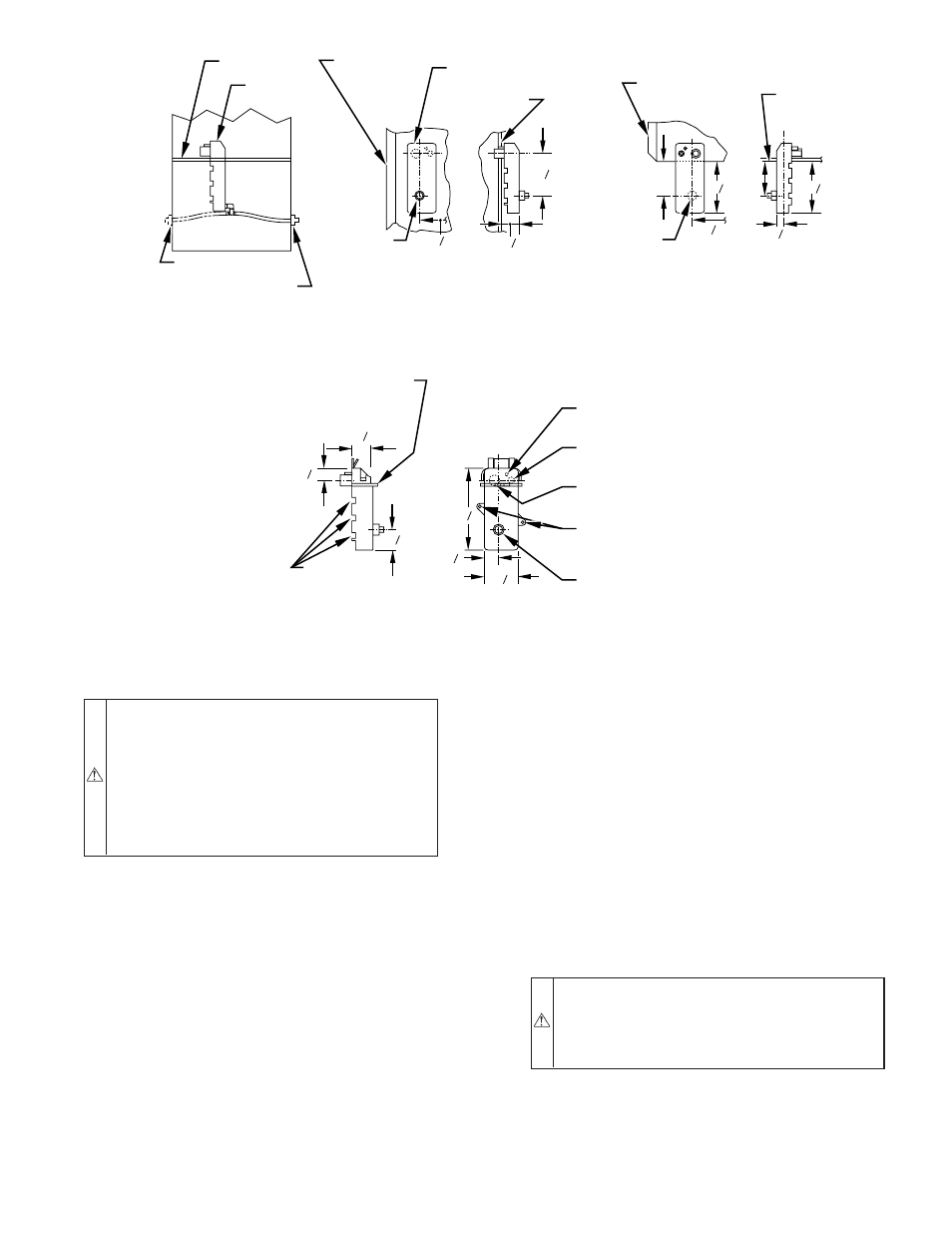

Some assembly and modifications are required for furnaces

installed in any of the 4 applications shown in Fig. 1. All drain and

pressure tubes are connected as shown in Fig. 6. See appropriate

application instructions for these procedures.

Fig. 5—Condensate Trap

A93026

1

⁄

2

OD

INDUCER HOUSING

DRAIN CONNECTION

1

⁄

4

OD

COLLECTOR BOX TO

TRAP RELIEF PORT

5

⁄

8

OD

COLLECTOR BOX

DRAIN CONNECTION

1

⁄

2

-IN. PVC OR CPVC

SCREW HOLE FOR

UPFLOW OR DOWN-

FLOW APPLICATIONS

(OPTIONAL)

1 4

2

7 8

1 8

7

SLOT FOR SCREW

HORIZONTAL

APPLICATION

(OPTIONAL)

WIRE TIE

GUIDES

(WHEN USED)

1 2

1

3 4

1

3 4

FRONT VIEW

SIDE VIEW

FURNACE

DOOR

FURNACE

DOOR

CONDENSATE

TRAP

78

1 4

26

4

FURNACE

SIDE

FURNACE

SIDE

1 2

1

1 4

26

4

3 4

5

3 4

5

4

SIDE VIEW

FRONT VIEW

END VIEW

FRONT VIEW

3 4

DOWNFLOW AND ALTERNATE

EXTERNAL UPFLOW APPLICATIONS

HORIZONTAL

APPLICATIONS

FIELD

DRAIN

CONN

FIELD

DRAIN

CONN

CONDENSATE

TRAP (INSIDE)

BLOWER SHELF

ALTERNATE DRAIN

TUBE LOCATION

UPFLOW APPLICATIONS

CONDENSATE TRAP

DRAIN TUBE LOCATION

—5—