Bryant 345MAV User Manual

Page 10

2. Inducer Housing Drain Tube

a. Remove and discard LOWER (molded) inducer housing

drain tube which was previously connected to conden-

sate trap.

b. Use inducer housing drain extension tube (violet label

and factory-supplied in loose parts bag) to connect

LOWER inducer housing drain connection to the con-

densate trap.

c. Determine appropriate length, cut, and connect tube.

d. Clamp tube to prevent any condensate leakage.

3. Relief Port Tube

a. Use smaller diameter tube (factory-supplied in loose

parts bag) to extend collector box tube (green label)

which was previously connected to the condensate trap.

b. Route extended collector box pressure tube to relief port

connection on the condensate trap.

c. Determine appropriate length, cut, and connect tube.

d. Clamp tube to prevent any condensate leakage.

C.

Condensate Trap Field Drain Attachment

Refer to Condensate Drain section for recommendations and

procedures.

D.

Pressure Switch Tubing

The LOWER collector box pressure tube (pink label) is factory

connected to the pressure switch for use when furnace is installed

in UPFLOW applications. This tube MUST be disconnected,

extended, rerouted, and then reconnected to the pressure switch in

HORIZONTAL LEFT applications.

NOTE:

See Fig. 10 or tube routing label on main furnace door to

check for proper connections.

Modify tube as described below.

1. Disconnect collector box pressure tube (pink label) attached

to pressure switch.

2. Use smaller diameter tube (factory-supplied in loose parts

bag) to extend tube disconnected in item 1.

3. Route extended tube:

a. Behind inducer housing.

b. Between blower shelf and inducer housing.

c. Behind inducer motor bracket.

d. Between inducer motor and pressure switch.

4. Determine appropriate length, cut, and reconnect tube to

pressure switch connection labeled COLLECTOR BOX.

E.

Condensate Trap Freeze Protection

Refer to Condensate Drain Protection section for recommenda-

tions and procedures.

F.

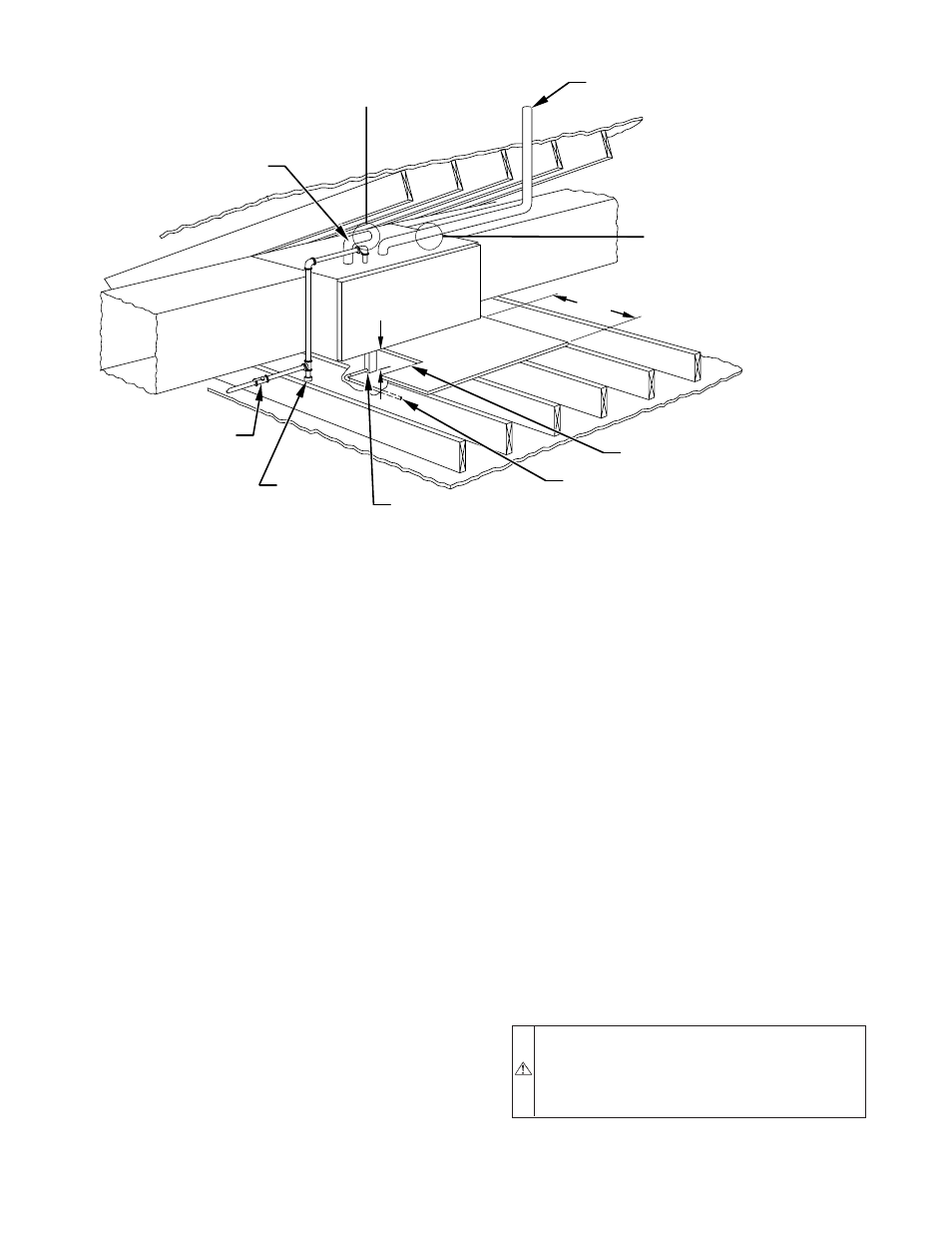

Construct a Working Platform

Construct working platform where all required furnace clearances

are met. (See Fig. 3 and 11.)

CAUTION:

The condensate trap MUST be installed

below furnace. See Fig. 5 for dimensions. The drain

connection to condensate trap must also be properly

sloped to an open drain. Failure to follow this caution will

result in intermittent unit operation.

NOTE:

Vent pipe length is restricted to a minimum of 5 ft. (See

Table 6.)

Fig. 11—Attic Location and Working Platform

A96184

VENT

MANUAL

SHUTOFF

GAS VALVE

SEDIMENT

TRAP

CONDENSATE

TRAP

DRAIN

ACCESS OPENING

FOR TRAP

30-IN. MIN

WORK AREA

A 12-IN. MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH

SHORT (5 TO 8 FT) VENT SYSTEMS

TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE.

A 3-IN. MINIMUM CLEARANCE

TO COMBUSTION-AIR INTAKE

IS REQUIRED.

5

3

⁄

4

″

NOTE: LOCAL CODES MAY REQUIRE A DRAIN PAN UNDER THE

FURNACE AND CONDENSATE TRAP WHEN A CONDENSING

FURNACE IS INSTALLED ABOVE FINISHED CEILINGS.

COMBUSTION–AIR

INTAKE

—10—