Bryant 345MAV User Manual

Page 41

WARNING:

Disconnect 115-v electrical power before

changing speed tap. Failure to follow this warning could

result in personal injury.

4. To change blower motor speed selections for heating mode,

remove blower motor lead from control center HEAT

terminal. (See Fig. 33.) Select desired blower motor speed

lead from 1 of the other motor leads and relocate it to HEAT

terminal. See Table 12 for lead color identification. Recon-

nect original lead on SPARE terminal.

Follow this same procedure for proper selection of COOL

speed selection.

C.

Blower Off Delay (Heat Mode)

The blower off delay has 4 adjustable settings from 90 sec to 180

sec. (See Table 13.) The blower off delay jumpers are located on

the furnace control board (See Fig. 33.) To change the blower off

delay setting, move the jumper from one set of pins on the control

board to the pins used for the desired blower off delay. Factory

blower off delay setting is 120 sec.

TABLE 13—BLOWER OFF DELAY SETUP POSITION

PINS

1 AND 2

2 AND 3

3 AND 4

4 AND 5

Time (in sec)

90

120

150

180

D.

Set Thermostat Heat Anticipator

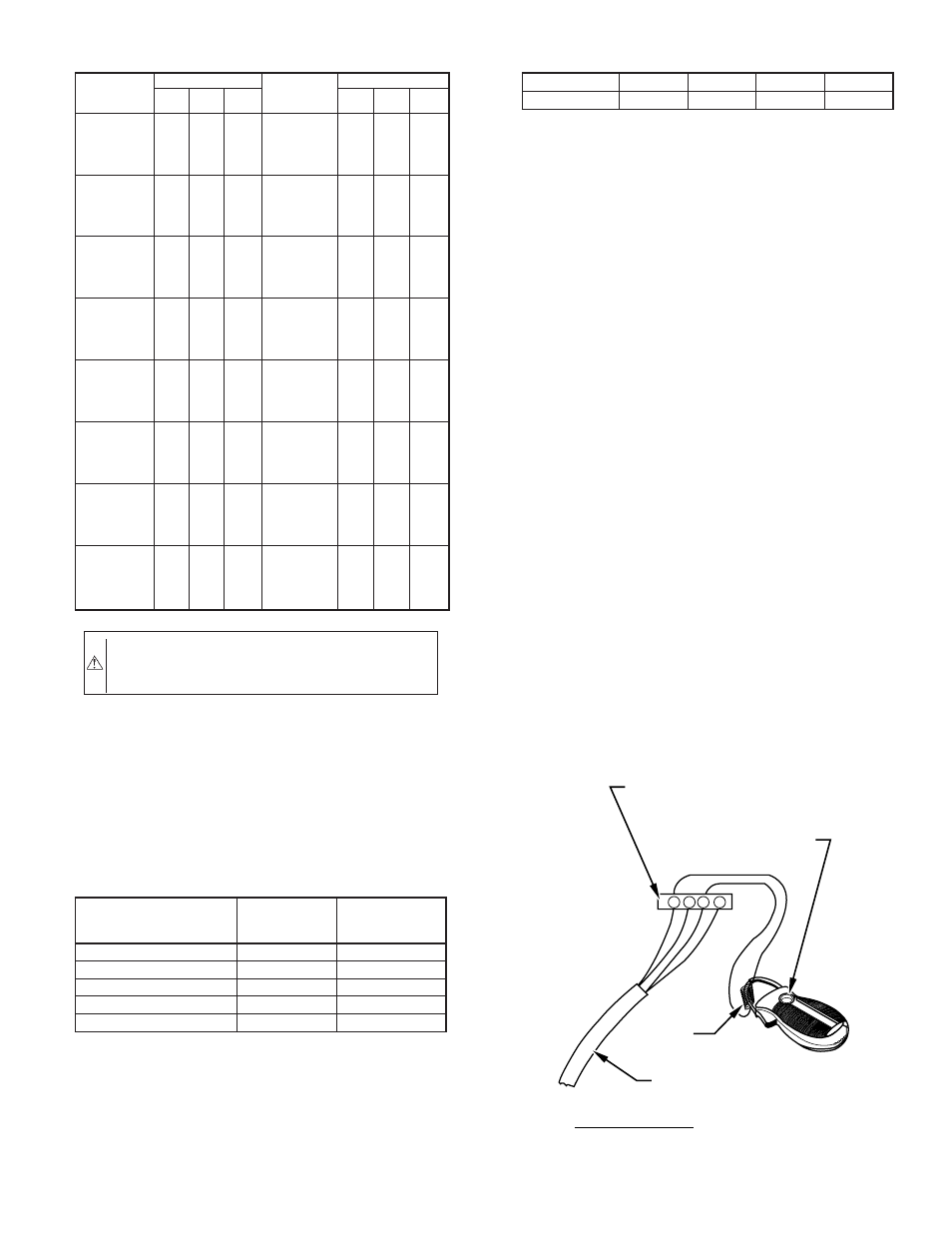

When using a nonelectronic thermostat, the thermostat heat

anticipator must be set to match amp draw of the electrical

components in R-W circuit. Accurate amp draw readings can be

obtained at thermostat subbase terminals R and W. Fig. 49

illustrates an easy method of obtaining actual amp draw. The amp

reading should be taken after blower motor has started and furnace

is heating. Connect ammeter wires as shown in Fig. 49. The

thermostat anticipator should NOT be in the circuit while measur-

ing current. If thermostat has no subbase, the thermostat must be

disconnected from R and W wires during current measurement.

See thermostat manufacturer’s instructions for adjusting heat

anticipator and for varying heating cycle length.

For an electronic thermostat, set cycle rate for 3 cycles per hour.

VI.

CHECK SAFETY CONTROLS

This section covers the safety controls that must be checked before

the installation is complete. The flame sensor, gas valve, and

pressure switch were all checked in the Start-up prodecure section

as part of normal operation.

A.

Check Primary Limit Control

This control shuts off combustion control system and energizes

air-circulating blower motor if furnace overheats. Recommended

method of checking this limit control is to gradually block off

return air after furnace has been operating for a period of at least

5 minutes. As soon as limit control has shut off burners, return-air

opening should be unblocked to permit normal air circulation. By

using this method to check limit control, it can be established that

limit is functioning properly and operates if there is a restricted

return-air supply or motor failure. If limit control does not function

during this test, cause must be determined and corrected.

B.

Check Pressure Switch

This control proves operation of draft inducer. Check switch

operation as follows:

1. Turn off 115-v power to furnace.

2. Remove main furnace door and disconnect inducer motor

lead wires from wire harness.

TABLE 11—GAS RATE (CU FT/HR)

SECONDS

FOR 1

REVOLUTION

SIZE OF TEST DIAL

SECONDS

FOR 1

REVOLUTION

SIZE OF TEST DIAL

1

cu ft

2

cu ft

5

cu ft

1

cu ft

2

cu ft

5

cu ft

10

11

12

13

14

360

327

300

277

257

720

655

600

555

514

1800

1636

1500

1385

1286

50

51

52

53

54

72

71

69

68

67

144

141

138

136

133

360

355

346

340

333

15

16

17

18

19

240

225

212

200

189

480

450

424

400

379

1200

1125

1059

1000

947

55

56

57

58

59

65

64

63

62

61

131

129

126

124

122

327

321

316

310

305

20

21

22

23

24

180

171

164

157

150

360

343

327

313

300

900

857

818

783

750

60

62

64

66

68

60

58

56

54

53

120

116

112

109

106

300

290

281

273

265

25

26

27

28

29

144

138

133

129

124

288

277

267

257

248

720

692

667

643

621

70

72

74

76

78

51

50

48

47

46

103

100

97

95

92

257

250

243

237

231

30

31

32

33

34

120

116

113

109

106

240

232

225

218

212

600

581

563

545

529

80

82

84

86

88

45

44

43

42

41

90

88

86

84

82

225

220

214

209

205

35

36

37

38

39

103

100

97

95

92

206

200

195

189

185

514

500

486

474

462

90

92

94

96

98

40

39

38

38

37

80

78

76

75

74

200

196

192

188

184

40

41

42

43

44

90

88

86

84

82

180

176

172

167

164

450

439

429

419

409

100

102

104

106

108

36

35

35

34

33

72

71

69

68

67

180

178

173

170

167

45

46

47

48

49

80

78

76

75

73

160

157

153

150

147

400

391

383

375

367

110

112

116

120

124

33

32

31

30

29

65

64

62

60

58

164

161

155

150

145

TABLE 12–SPEED SELECTOR

COLOR

SPEED

FACTORY-

SHIPPED

CONNECTION

Black

High

Cool

Yellow (When Present)

Medium High

Spare

Blue

Medium Low

Heat

Red

Low

Fan

White

Common

Com

Fig. 49—Amp Draw Check with Ammeter

A80201

R

Y W G

10 TURNS

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

HOOK-AROUND

VOLT/AMMETER

EXAMPLE:

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

= 0.5 AMPS FOR THERMOSTAT SETTING

FROM UNIT 24-VOLT

TERMINAL BLOCK

—41—