Bryant 345MAV User Manual

Page 30

WARNING:

Vent pipe must be installed and fully

seated against inducer housing internal stop. Clamp must

be tightened to prevent any condensate leakage. Failure to

follow this warning could result in electrical shock, fire,

personal injury, or death.

NOTE:

A 2-in. diameter pipe must be used within the furnace

casing. Make all pipe diameter transitions outside furnace casing.

4. Be certain that mating surfaces of inducer housing connec-

tion, elastomeric coupling, and 2-in. diameter vent pipe are

clean and dry. Assemble the elastomeric (rubber) vent

coupling (with 2 loose clamps) onto inducer housing

connection. Insert the 2-in. diameter vent pipe through the

elastomeric (rubber) coupling and fully into inducer hous-

ing connection until it bottoms on the internal stop. Tighten

both clamps to secure the pipe to inducer housing. Tighten

the clamp screws to 15 in.-lb. of torque.

VENT EXTENSION PIPE

Some furnaces are supplied with a PVC vent extension pipe

(2-in. diameter by 12-in. long). This pipe has a built-in

channel to assist vent condensate disposal. When this vent

extension pipe is supplied, it must be used to connect the

field vent pipe to furnace inducer housing on ALL upflow

and downflow applications.

NOTE:

See label on vent extension pipe for proper installation.

This pipe may be shortened if an elbow is used to connect vent

extension tube to field-installed vent pipe.

5. Working from furnace to outside, cut pipe to required

length(s).

6. Deburr inside and outside of pipe.

7. Chamfer outside edge of pipe for better distribution of

primer and cement.

8. Clean and dry all surfaces to be joined.

9. Check dry fit of pipe and mark insertion depth on pipe.

NOTE:

It is recommended that all pipes be cut, prepared, and

preassembled before permanently cementing any joint.

10. After pipes have been cut and preassembled, apply gener-

ous layer of cement primer to pipe fitting socket and end of

pipe to insertion mark. Quickly apply approved cement to

end of pipe and fitting socket (over primer). Apply cement

in a light, uniform coat on inside of socket to prevent

buildup of excess cement. Apply second coat.

11. While cement is still wet, twist pipe into socket with 1/4

turn. Be sure pipe is fully inserted into fitting socket.

12. Wipe excess cement from joint. A continuous bead of

cement will be visible around perimeter of a properly made

joint.

13. Handle pipe joints carefully until cement sets.

14. Support vent piping a minimum of every 5 ft (3 ft for

SDR-21 or -26 PVC) using perforated metal hanging strap.

15. Slope vent pipe downward toward furnace a minimum of

1/4 in. per linear ft with no sags between hangers.

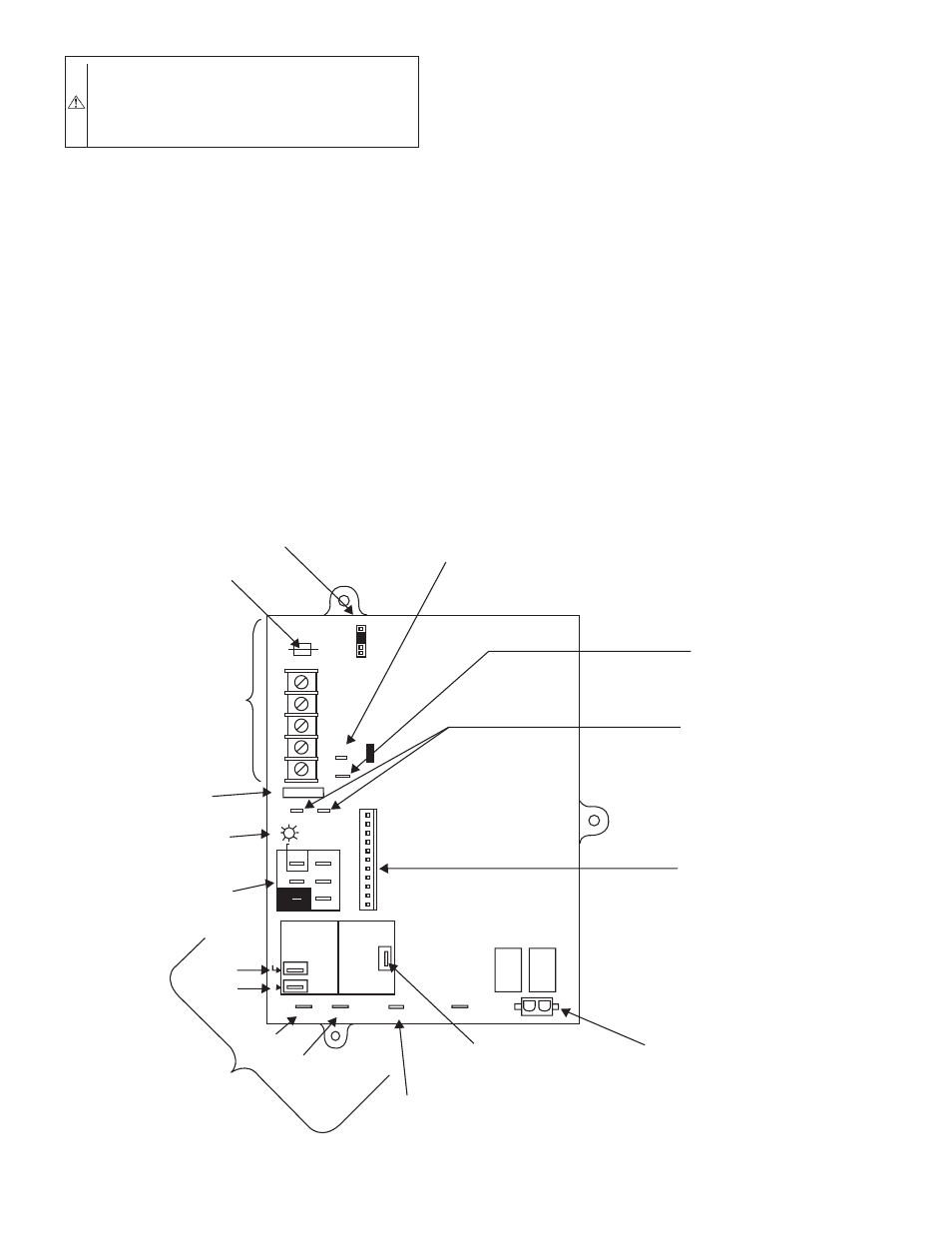

Fig. 33—Control Center

A02100

BL

W

NUETRAL

ST

A

TUS CODE LED

SEC-2 SEC-1

EAC-2 L2

FUSE 3-AMP

0.5 AMP@24VAC

HUM

TEST/TWIN

G Com

W

Y R

24V

120 180

90 150

BLOWER OFF-DELAY

PL

T 1

COOL HEA

T

SPARE-1 SPARE-2

EAC-1

1-AMP@

115VAC

PR-1

L1

PL2 1

24-V THERMOSTAT

TERMINALS

3-AMP FUSE

LED OPERATION &

DIAGNOSTIC LIGHT

115-VAC(L2)NEUTRAL

CONNECTIONS

COOL

HEAT

SPARE-1

SPARE-2

BLOWER SPEED

SELECTION TERMINALS

EAC-1 TERMINAL

(115-VAC 1.0 AMP MAX.)

115 VAC (L1) LINE

VOLTAGE CONNECTION

PL2-HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

PL1-LOW VOLTAGE MAIN

HARNESS CONNECTOR

TRANSFORMER 24-VAC

CONNECTIONS

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP MAX.)

TWINNING AND/OR

COMPONENT TEST

TERMINAL

BLOWER OFF-DELAY

J2

J2 JUMPER

PL

T

—30—