Bryant 345MAV User Manual

Page 19

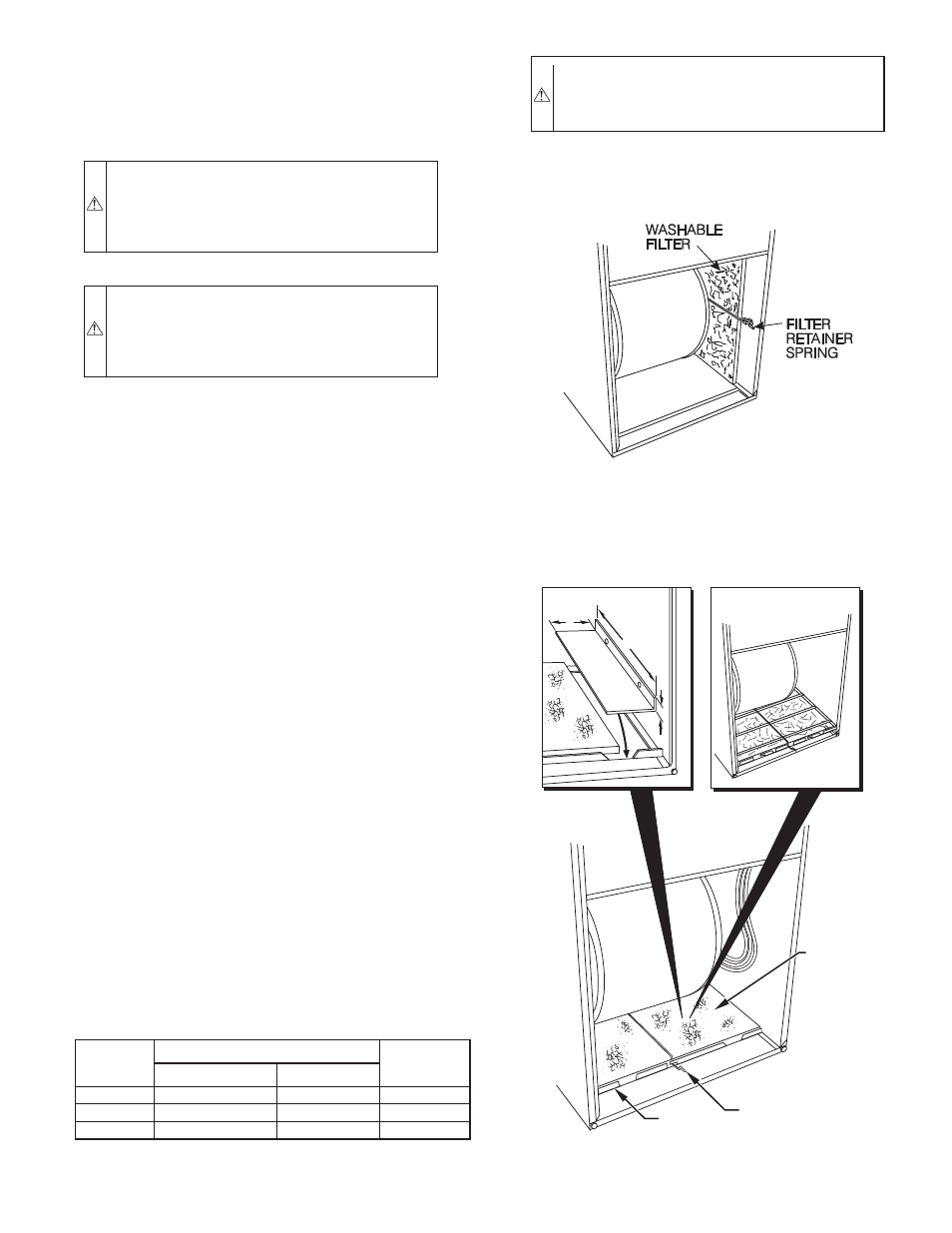

Factory-supplied washable framed filters are shipped in blower

compartment. Determine location for filter and relocate filter

retaining wire if necessary. See Table 2 to determine correct filter

size for desired filter location. Table 2 indicates filter size,

location, and quantity shipped with this furnace. See Fig. 2 for

location and size of bottom and side return-air openings.

CAUTION:

Use care when cutting support rods in filters

to protect against flying pieces and sharp rod ends. Wear

safety glasses, gloves, and appropriate protective cloth-

ing. Failure to follow this caution could result in minor

personal injury.

CAUTION:

Air delivery above 1800 CFM requires that

both sides, a combination of 1 side and bottom, or bottom

only of furnace be used for return air. Failure to follow

this caution will result in intermittent unit operation or

performance satisfaction.

NOTE:

Side return-air openings can ONLY be used in UPFLOW

configurations. Install filter(s) as shown in Fig. 25.

Bottom return-air opening may be used with all 4 orientations.

Filter may need to be cut to fit some furnace widths. Install filter

as shown in Fig. 26.

NOTE:

Remove and discard bottom closure panel when bottom

inlet is used.

F.

Bottom Closure Panel

These furnaces are shipped with bottom enclosure panel installed

in bottom return-air opening. This panel MUST be in place when

side return air is used.

To remove bottom closure panel, perform following:

1. Tilt or raise furnace and remove 2 screws holding front

filler panel. (See Fig. 27.)

2. Rotate front filler panel downward to release holding tabs.

3. Remove bottom closure panel.

4. Reinstall front filler panel and screws.

G.

Gas Piping

Gas piping must be installed in accordance with national and local

codes. Refer to current edition of NFGC in the United States.

Canadian installations must be made in accordance with NSCNG-

PIC and all authorities having jurisdiction. Gas supply line should

be a separate line running directly from meter to furnace, if

possible. Refer to Table 3 for recommended gas pipe sizing. Risers

must be used to connect to furnace and to meter. Support all gas

piping with appropriate straps, hangers, etc. Use a minimum of 1

hanger every 6 ft. Joint compound (pipe dope) should be applied

sparingly and only to male threads of joints. Pipe dope must be

resistant to propane gas.

CAUTION:

Connect gas pipe to furnace using a backup

wrench to avoid damaging gas controls. Failure to follow

this caution will result in intermittent unit operation or

performance satisfaction.

TABLE 2—FILTER INFORMATION

FURNACE

CASING

WIDTH (IN.)

FILTER SIZE (IN.)*

FILTER TYPE

FRAMED

Side Return

Bottom Return

17-1/2

(1) 16 X 25 X 1†

(1) 16 X 25 X 1†

Cleanable

21

(1) 16 X 25 X 1

(1) 20 X 25 X 1†

Cleanable

24-1/2

(1 or 2) 16 X 25 X 1 (1) 24 X 25 X 1†

Cleanable

* Filters may be field modified by cutting filter material and support rods (3) in

filters. Alternate sizes can be ordered from your distributor or dealer.

† Factory-provided with furnace.

Fig. 25—Filter Installed for Side Inlet

A00217

Fig. 26—Bottom Filter Arrangement

A00290

WASHABLE

FILTER

FILTER

SUPPORT

FILTER

RETAINER

17

1

⁄

2

-IN. WIDE

CASINGS ONLY:

INSTALL FIELD-SUPPLIED

FILTER FILLER STRIP

UNDER FILTER.

1

″

24

1

/

2

″

3

″

21-IN. WIDE

CASINGS ONLY:

SUPPORT RODS (3)

EXTEND 1/4" ON EACH

SIDE OF FILTER AND

REST ON CASING FLANGE

—19—