Installation – Bryant 345MAV User Manual

Page 2

Check Pressure Switch.................................................41

CHECKLIST......................................................................42

SAFETY CONSIDERATIONS

CAUTION:

Application of this furnace should be in-

doors with special attention given to vent sizing and

material, gas input rate, air temperature rise, unit leveling,

and unit sizing. Improper installation or misapplication of

furnace can require excessive servicing or cause prema-

ture component failure.

WARNING:

Improper installation, adjustment, alter-

ation, service, maintenance, or use can cause carbon

monoxide poisoning, explosion, fire, electrical shock, or

other conditions which may cause personal injury or

property damage. Consult a qualified installer, service

agency, local gas supplier, or your distributor or branch

for information or assistance. The qualified installer or

agency must use only factory-authorized and listed kits or

accessories when modifying this product. Failure to

follow this warning could result in electrical shock, fire,

personal injury, or death.

Installing and servicing heating equipment can be hazardous due to

gas and electrical components. Only trained and qualified

personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations must

be performed by trained service personnel. When working on

heating equipment, observe precautions in literature, on tags, and

on labels attached to or shipped with unit and other safety

precautions that may apply.

These instructions cover the minimum requirements and conform

to existing national standards and safety codes. In some instances,

these instructions exceed certain local codes and ordinances,

especially those that may not have kept up with changing residen-

tial construction practices. We require these instructions as a

minimum for a safe installation.

Wear safety glasses and work gloves. Have a fire extinguisher

available during start-up and adjustment procedures and service

calls.

CAUTION:

Sheet metal parts may have sharp edges or

burrs. Use care and wear appropriate protective clothing

and gloves when handling parts. Failure to follow this

caution could result in personal injury.

Recognize safety information. This is the safety-alert symbol

.

When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand these signal words DANGER, WARNING, CAU-

TION, and NOTE. These words are used with the safety-alert

symbol. DANGER identifies the most serious hazards which will

result in severe personal injury or death. WARNING signifies

hazards which could result in personal injury or death. CAUTION

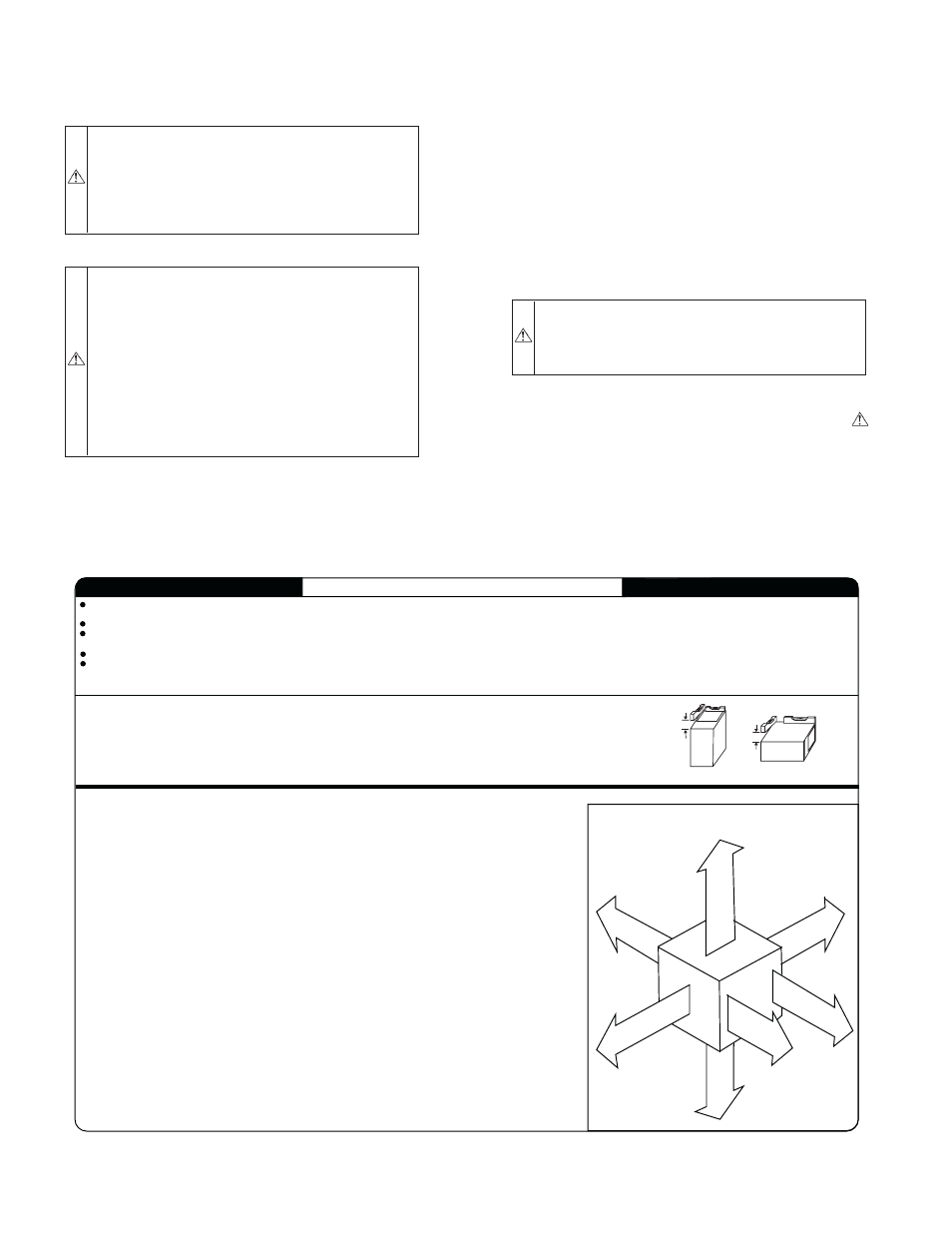

Fig. 3—Clearances to Combustibles

A02248

This forced air furnace is equipped for use with natural gas at altitudes 0 - 10,000 ft (0 - 3,050m), except 140 size furnaces are only approved for altitudes 0 - 7,000 ft.

(0 - 2,135m).

An accessory kit, supplied by the manufacturer, shall be used to convert to propane gas use or may be required for some natural gas applications.

This furnace is for indoor installation in a building constructed on site. This furnace may be installed in a manufactured (mobile) home when stated on rating plate and

using factory authorized kit.

This furnace may be installed on combustible flooring in alcove or closet at Minimum Inches Clearance To Combustible Construction as described below.

This furnace requires a special venting system. Refer to the installation instructions for parts list and method of installation. This furnace is for use with schedule-40 PVC,

PVC-DWV, CPVC, or ABS-DWV pipe, and must not be vented in common with other gas-fired appliances. Construction through which vent/air intake pipes may be

installed is maximum 24 inches (600 mm), minimum 3/4 inches (19 mm) thickness (including roofing materials).

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

*

Minimum front clearance for service 30 inches (762mm).

140 size furnaces require 1 inch back clearance to combustible materials.

For installation on combustible floors only when installed on special base No. KGASB0201ALL,

Coil Assembly, Part No. CD5 or CK5, or Coil Casing, Part No. KCAKC.

Line contact is permissible only between lines formed by intersections of top and two sides of

furnace jacket, and building joists, studs, or framing.

Clearance shown is for air inlet and air outlet ends.

120 and 140 size furnaces require 1 inch bottom clearance to combustible materials.

Ø

Clearance in inches.

Vent clearance to

combustibles 0".

This furnace is approved for UPFLOW, DOWNFLOW and

HORIZONTAL installations.

*

BO

T

T

O

M

0"

Ø

3"

0"

§

0"

T

O

P/

PL

EN

U

M

1"

0"

§

30

MIN

ALL POSITIONS:

DOWNFLOW POSITIONS:

HORIZONTAL POSITIONS:

S I

D E

F

R

O

N

T

B

C

K

A

S

E

R V

I

E

C

F R

ON

T

S I

D E

U

F

R N

A C

E

Clearance arrows

do not change with

furnace orientation.

†

†

† †

UPFLOW OR

DOWNFLOW

1/2" MAX

LEVEL (0")TO

† †

328066-201 REV. A

LIT -TOP

INSTALLATION

§

For upflow and downflow applications, furnace must be installed level, or pitched within 1/2" of level. For a

horizontal application, the furnace must be pitched minimum 1/4" to maximum of 1/2" forward for proper

drainage. See Installation Manual for IMPORTANT unit support details on horizontal applications.

HORIZONTAL

FRONT

FRONT

MIN 1/4" TO 1/2" MAX

—2—