Bryant 345MAV User Manual

Page 34

CAUTION:

These furnaces are equipped with a manual

reset limit switch in burner box. This switch will open

and shut off power to gas valve if an overheat condition

(flame rollout) occurs in burner enclosure. Correct inad-

equate combustion-air supply or improper venting condi-

tion and reset switch. DO NOT jumper this switch.

Failure to follow this caution will result in minor unit

operation or performance satisfaction.

Before operating furnace, check flame rollout manual reset switch

for continuity. If necessary, press button to reset switch.

II.

PRIME CONDENSATE TRAP WITH WATER

CAUTION:

Condensate trap must be PRIMED or

proper draining may not occur. The condensate trap has 2

internal chambers which can ONLY be primed by pour-

ing water into the inducer drain side of condensate trap.

Failure to follow this caution will result in minor unit

operation or performance satisfaction.

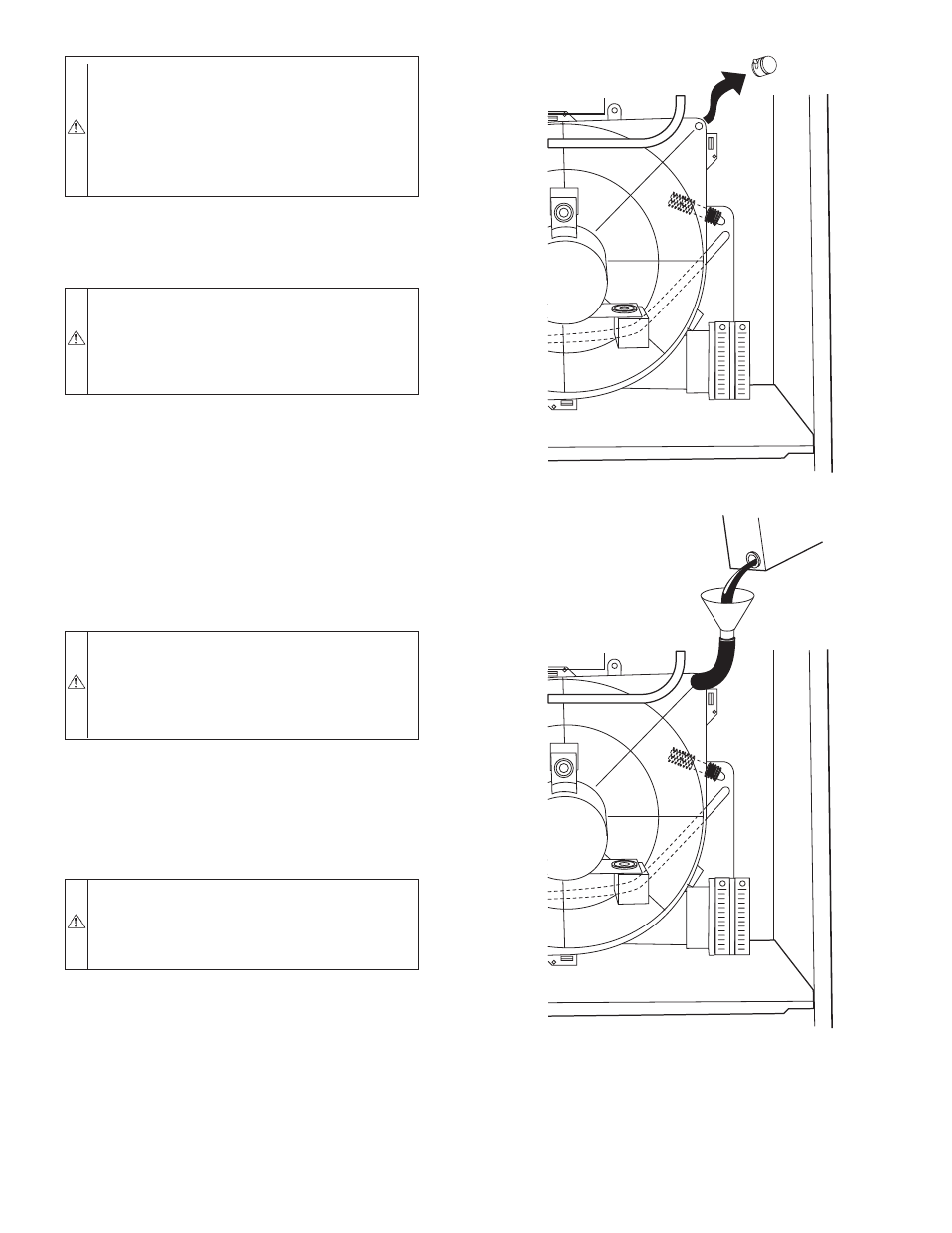

1. Remove upper inducer housing drain connection cap. (See

Fig. 44.)

2. Connect field-supplied 1/2-in. ID tube to upper inducer

housing drain connection.

3. Insert field-supplied funnel into tube.

4. Pour 1 quart of water into funnel/tube. Water should run

through inducer housing, overfill condensate trap, and flow

into open field drain. (See Fig. 45.)

5. Remove funnel and tube from inducer housing and replace

drain connection cap and clamp.

III.

PURGE GAS LINES

WARNING:

Never purge a gas line into a combustion

chamber. Never test for gas leaks with an open flame. Use

a commercially available soap solution made specifically

for the detection of leaks to check all connections. Failure

to follow this warning could result in fire, explosion,

personal injury, or death.

IV.

SEQUENCE OF OPERATION

If not previously done, purge lines after all connections have been

made and check for leaks.

Using the schematic diagram in Fig. 32, follow the sequence of

operation through the different modes. Read and follow the wiring

diagram very carefully.

CAUTION:

Furnace control must be grounded for

proper operation, or control will lock out. Control is

grounded throug green/yellow wire connected to gas

valve and burner box screw. Failure to follow this caution

will result in intermittent unit operation.

NOTE:

If a power interruption occurs during a call for heat (W),

the control will start a 90-second blower-only ON period two

seconds after power is restored, if the thermostat is still calling for

gas heating. The red LED light will flash code 12 during the

90-second period, after which the LED will be ON continuous, as

long as no faults are detected. After the 90-second period, the

furnace will respond to the thermostat normally.

The blower door must be installed for power to be conducted

through the blower door interlock switch ILK to the furnace

control CPU, transformer TRAN, inducer motor IDM, blower

motor BLWM, hot-surface igniter HSI, and gas valve GV.

1. Heating

(See Fig. 30 for thermostat connections.)

The wall thermostat

″

calls for heat

″

, closing the R to W

circuit. The furnace control performs a self-check, verifies

the pressure switch contacts PRS are open, and starts the

inducer motor IDM.

Fig. 45—Filling Condensate Trap

A99119

Fig. 44—Inducer Housing Drain Cap

A99118

—34—