Bryant 345MAV User Manual

Page 40

CANADA

At installation altitudes from 2000 to 4500 ft, this

furnace must be derated 5% by an authorized Gas

Conversion Station. To determine correct input rate for

altitude, see example above and use 0.95 as derate

multiplier factor.

b. Reinstall burner box cover.

NOTE:

Burner box cover MUST be isntalled while clocking gas

input rate.

c. Gas valve regulator seal cap MUST be installed.

d. Turn off all other gas appliances and pilots.

e. Start furnace and let operate for 3 minutes.

f. Measure time (in sec) for gas meter test dial to complete

1 revolution.

g. Refer to Table 11 for cu ft of gas per hr.

h. Multiply gas rate (cu ft/hr) X heating value (Btu/cu ft)

using natural gas heating value from local gas

utility/supplier.

EXAMPLE:

Btu heating input = Btu/cu ft X cu ft/hr Heating value of

gas = 975 Btu/cu ft

Time for 1 revolution of 2-cu ft dial = 70 sec

Gas rate = 103 cu ft/hr (from Table 11)

Btu heating input = 103 X 975 = 100,425 Btuh

In this example, the orifice size and manifold pressure

adjustment is within

±

2 percent of the furnace input rate.

B.

Set Temperature Rise

CAUTION:

Temperature rise must be within limits

specified on unit rating plate. Recommended operation is

at midpoint of rise or slightly above. Failure to follow this

caution may result in primary and secondary heat ex-

changers failure.

Determine and adjust air temperature rise as follows:

1. Place thermometers in return and supply ducts as close to

furnace as possible. Be sure thermometers do not see heat

exchanger so that radiant heat does not affect readings. This

practice is particularly important with straight-run ducts.

2. When thermometer readings stabilize, subtract return-air

temperature from supply-air temperature to determine air

temperature rise.

3. Adjust temperature rise by adjusting blower speed. Increase

blower speed to reduce temperature rise. Decrease blower

speed to increase temperature rise.

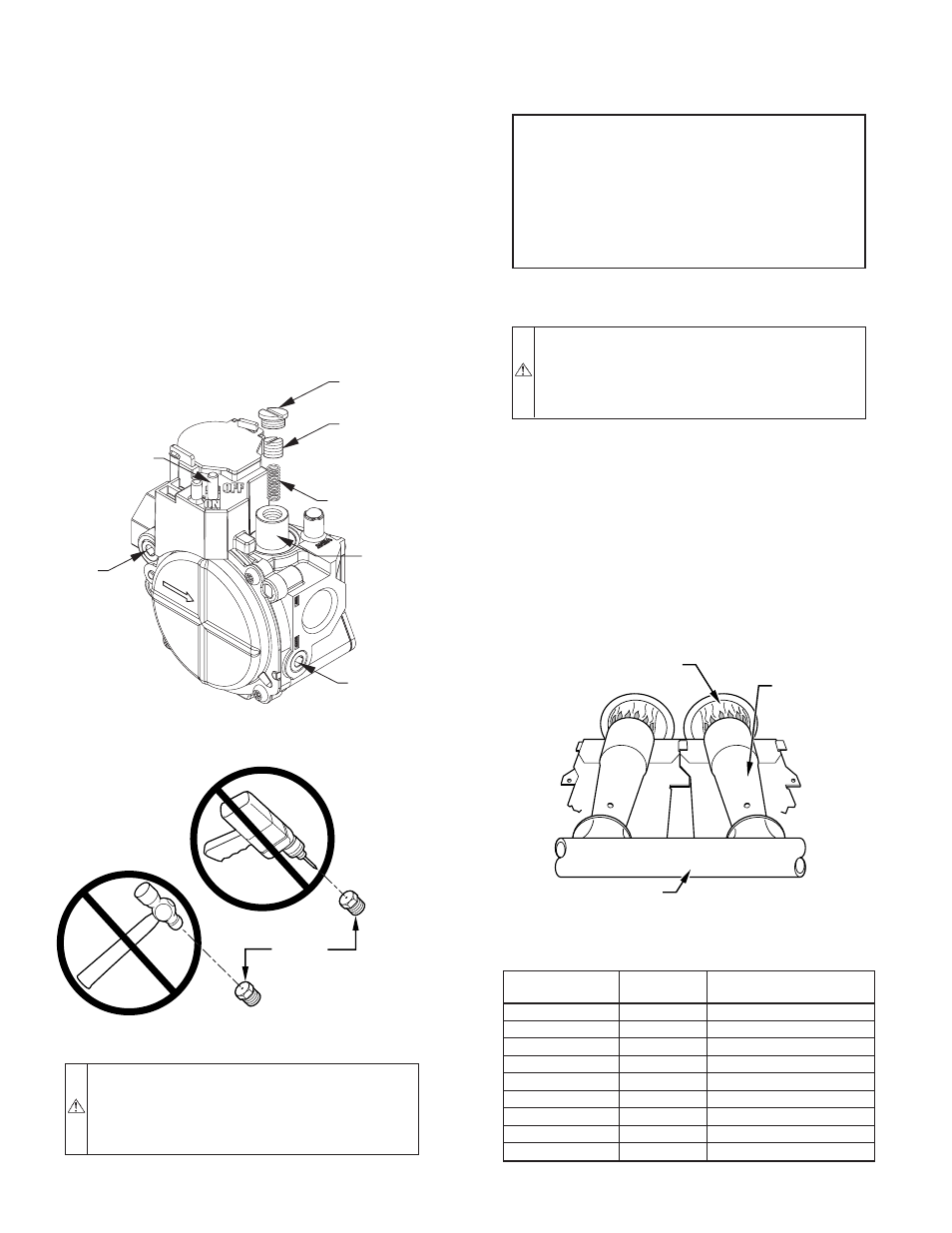

Fig. 46—Redundant Automatic Gas Valve

A03142

REGULATOR

SEAL CAP

REGULATOR

ADJUSTMENT

SCREW

REGULATOR SPRING

(PROPANE - WHITE, 6 TURNS

NATURAL - SILVER, 10 TURNS)

GAS PRESSURE

REGULATOR

ADJUSTMENT

MANIFOLD

PRESSURE TAP

INLET

PRESSURE TAP

ON/OFF SWITCH

Fig. 47—Orifice Holes

CAUTION:

DO NOT redrill orifices. Improper drilling

(burrs, out-of-round holes, etc.) can cause excessive

burner noise and misdirection of burner flames. This can

result in flame impingement of burners and heat exchang-

ers causing failures.

A93059

BURNER

ORIFICE

Fig. 48—Burner Flame

A89020

;;

;;

BURNER FLAME

BURNER

MANIFOLD

TABLE 10—ALTITUDE DERATE MULTIPLIER FOR U.S.A.

ALTITUDE

(FT)

% OF

DERATE

DERATE MULTIPLIER

FACTOR FOR U.S.A*

0—2000

0

1.00

2001—3000

4—6

0.95

3001—4000

6—8

0.93

4001—5000

8—10

0.91

5001—6000

10—12

0.89

6001—7000

12—14

0.87

7001—8000

14—16

0.85

8001—9000

16—18

0.83

9001—10,000

18—20

0.81

* Derate multiplier factor is based on midpoint altitude for altitude range.

—40—