Goulds Pumps 3600 - IOM User Manual

Page 93

Maintenance

b) Install the dowel pins in the pre-drilled dowel pin holes between the housing flange and

the head-bearing flange.

c) Tighten the nuts (427J) on the bearing housing to the head studs (371T).

d) Place the upper half of the sleeve bearing (117) on the shaft, moving the oil rings aside.

When the bearing top half is in place, move the oil rings back into the bearing housing

and sleeve grooves.

8. Install the upper half of the bearing housing (134A).

9. Place the outboard oil ring (114) on the oil-ring sleeve (443B).

10. Adjust the end play with the gasket (361A) and the thrust end cover (109A).

When new bearings are installed, you must measure the axial end play:

a) Bolt the end cover to the thrust housing.

b) Move the shaft axially from the coupling end.

c) Measure the shaft axial movement with a dial indicator mounted on the radial bearing

housing.

This table shows the clearance requirements between the thrust bearing end cover and the

bearing:

Bearing type

Clearance in inches (millimeters)

Ball/ball

0.005–0.010 (0.127–0.254)

Sleeve/ball

0.005–0.010 (0.127–0.254)

Sleeve/Kingsbury

0.010–0.013 (0.254–0.330)

11. Install the thrust bearing outboard-end cover (109A), with the gasket (361A). Tighten the

end cover to the housing with the capscrews (371C).

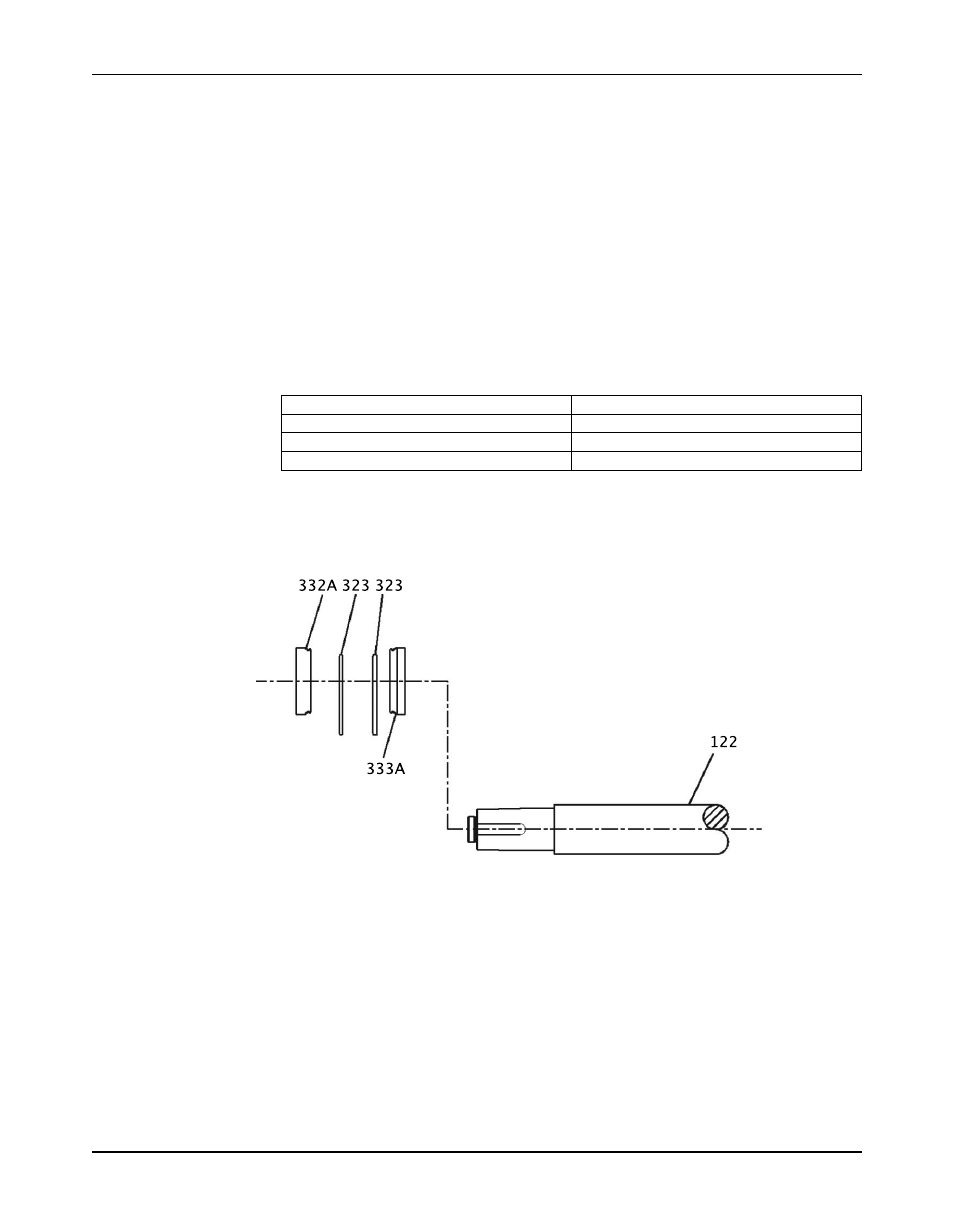

Assemble the radial end (sleeve/ball bearing pumps)

1. Install the inboard labyrinth seal (333A).

2. Place the oil rings (323) on the shaft.

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual

91