Goulds Pumps 3600 - IOM User Manual

Page 80

Maintenance

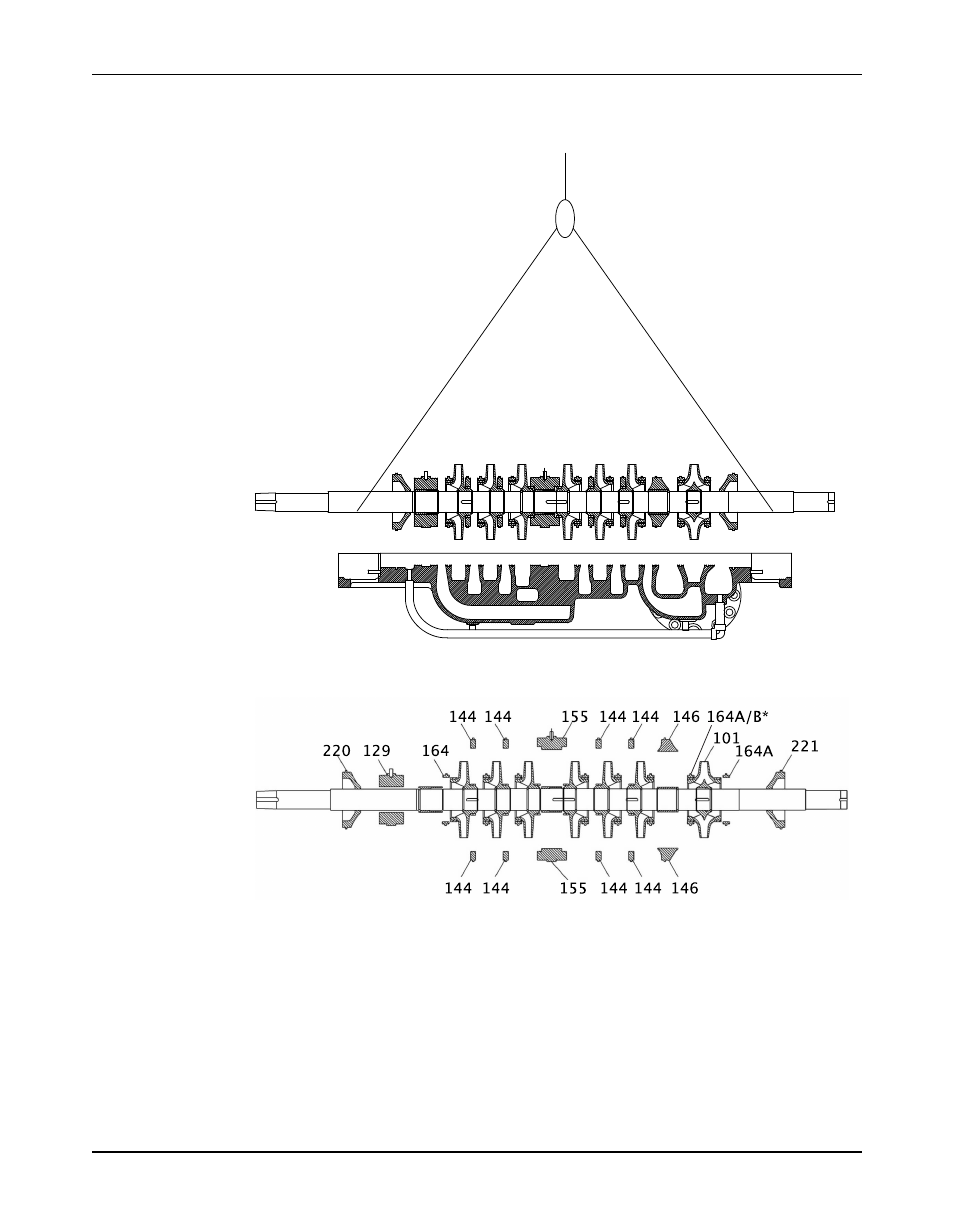

3. Position one sling between the throttle bushing sleeve (128) and the impeller and a second

sling in front of the first stage impeller (101). Lower the rotating assembly into the lower half

of the casing to the point where the stationary-groove locks engage.

4. Assemble the first-stage impeller casing ring (164A), the final-series casing ring (164), the

throttle bushing (129), and both seal chambers (220, 221).

* 164A for 4x6-10 and 4x6-11 pumps. 165B for all other pump sizes.

5. Lower the rotating assembly, making sure all stationary parts fit into the groove locks.

6. While maintaining tension on the rotating assembly, slide the lower half of all stage rings

(144), the center bushing (155), and the diaphragm (146), if applicable, into the lower half

of the casing.

7. Assemble the upper half of each component and tighten the socket head capscrews.

8. You must center the rotating element inside the casing whenever the bearings are

replaced:

a) Push the rotating element towards the coupling end until it stops.

b) Measure the distance from the thrust bearing shoulder on the shaft to the bearing

housing face on the casing.

78

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual