Goulds Pumps 3600 - IOM User Manual

Page 60

Maintenance

The bearing housing gaskets (360A) will remain on the end covers (109A or 160).

2. Remove the dowel pins (469J) between the bearing housing flange and the head flange.

The connection point of the housing to the casing is referred to as the saddle.

3. Unbolt the bearing housing from the saddle by removing the four nuts (427J).

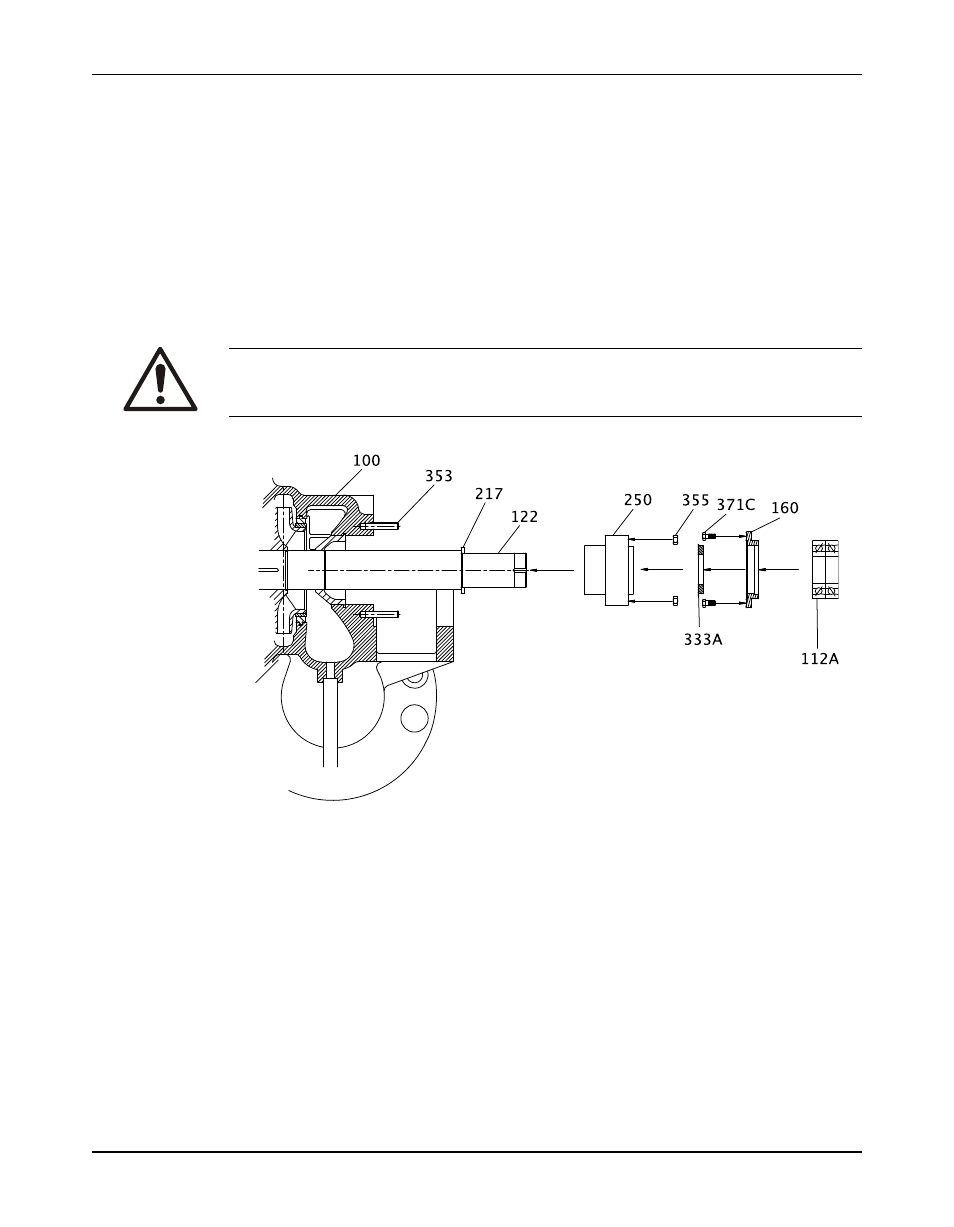

4. Remove the studs (371T). Rotate the bearing housing in order to remove the inboard end

cover bolts (371C).

5. Remove the oil ring (114).

6. Pull the bearing housing (134) off the shaft.

7. Remove the locknut (136) and the lockwasher (382).

8. Remove the oil ring sleeve (443B), which is held in place by the thrust locknut (136).

9. Use a bearing puller in order to remove the thrust bearing (112A) from the shaft (122).

The inner race on this inner duplex bearing remains on the shaft when the bearing is pulled.

Remove this inner race by applying heat. Do this away from the pump site.

WARNING:

The pump may handle hazardous and/or toxic liquids. Trapped or undrained liquid can cause explosions

when heat is applied. Never apply heat at the pump site for this reason. Heat can also distort machined

surfaces.

All pumps have a bearing spacer (217).

10. Remove the inboard bearing cover (160), the inboard labyrinth seal (333A), and the inner

bearing cover bolts (371C).

11. Remove the seal plate nuts (355) and the mechanical seal (250).

Refer to the instructions provided by the mechanical seal manufacturer.

58

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual