Bearing lubrication, Oil volumes – Goulds Pumps 3600 - IOM User Manual

Page 41

Commissioning, Startup, Operation, and Shutdown

Bearing lubrication

Precautions

WARNING:

Make sure to properly lubricate the bearings. Failure to do so can result in excess heat generation,

sparks, and premature failure.

NOTICE:

Avoid equipment damage. Refer to driver/coupling/gear manufactures IOM for instructions and

recommendations for lubrication.

Pumps are shipped without oil

You must lubricate oil-lubricated bearings at the job site.

Ring oil lubrication

Ring oil-lubricated bearings are standard.Sleeve/ball bearings are optional. Bearing housings

are supplied with constant-level oilers and sight glasses. Make sure that oil rings are properly

seated in the grooves in the shaft.

Pure or purge oil-mist lubrication

Pure or purge oil mist are optional features. Follow the oil-mist generator manufacturer's

instructions. The inlet and outlet connections are located on the top and bottom of the bearing

housing, respectively.

Oil volumes

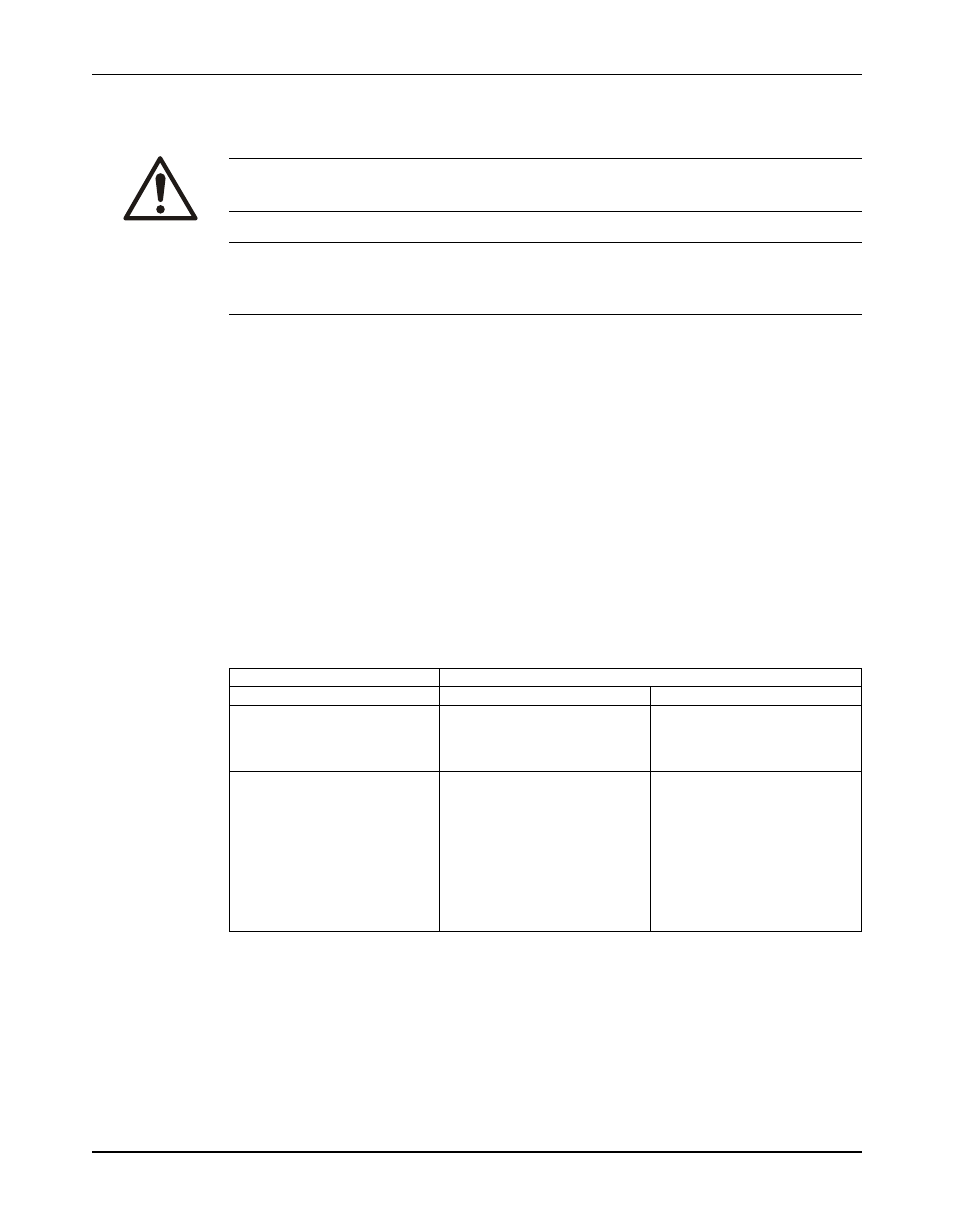

Oil volume requirements for ball/ball and sleeve/ball bearings

This table shows the required amount of oil for oil-lubricated bearings.

All frames in this table use a Watchdog Oiler, which has a capacity of 4 oz. (118 ml).

Size

Bearing housing oil volume

ounces

milliliters

3x4-8

50 (ball/ball)

1480 (ball/ball)

3x4-9

50/100 (sleeve/ball)

1480/2960 (sleeve/ball)

3x6-9

3x6-10

3x4-12 1/2

80 (ball/ball)

2365 (ball/ball)

4x6-10

120/220 (sleeve/ball)

3550/6505 (sleeve/ball)

4x6-11

4x6-12

6x8-11

6x8-13

6x8-14

8x10-13

10x12-14 1/2

10x12-15 1/2

Oil volume requirements for sleeve/Kingsbury type bearings

The sleeve/Kingsbury type bearing is a pressurized lubrication system where oil is flowed into

the bearing. This system does not have an oil sump. The system requires a flow rate of 0.5

gpm (0.12 m

3

/hr) for the sleeve bearing and 1.0 gpm (0.23 m

3

/hr) for the Kingsbury bearing at

15 psi (100 kPA).

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual

39