Goulds Pumps 3600 - IOM User Manual

Page 71

Maintenance

Impeller replacement

This table shows the criteria for replacing the impeller:

Impeller parts

When to replace

Impeller vanes

• When grooved deeper than 1/16 in. (1.6 mm),

or

• When worn evenly more than 1/32 in. (0.8 mm)

Pumpout vanes

When worn or bent more than 1/32 in. (0.8 mm)

Vane edges

When you see cracks, pitting, or corrosion damage

Wear ring surfaces

When the clearance to the casing wear ring has

increased by 50% over the values in the Minimum

running clearances table

Impeller checks

• Check and clean the impeller bore diameter.

• Check the impeller balance. Rebalance the impeller if it exceeds the ISO G1.0 (4W/N)

criteria.

NOTICE:

You must have extremely accurate tooling equipment to balance impellers to the ISO G1.0

criteria. Do not attempt to balance impellers to this criteria unless this type of tooling and

equipment is available.

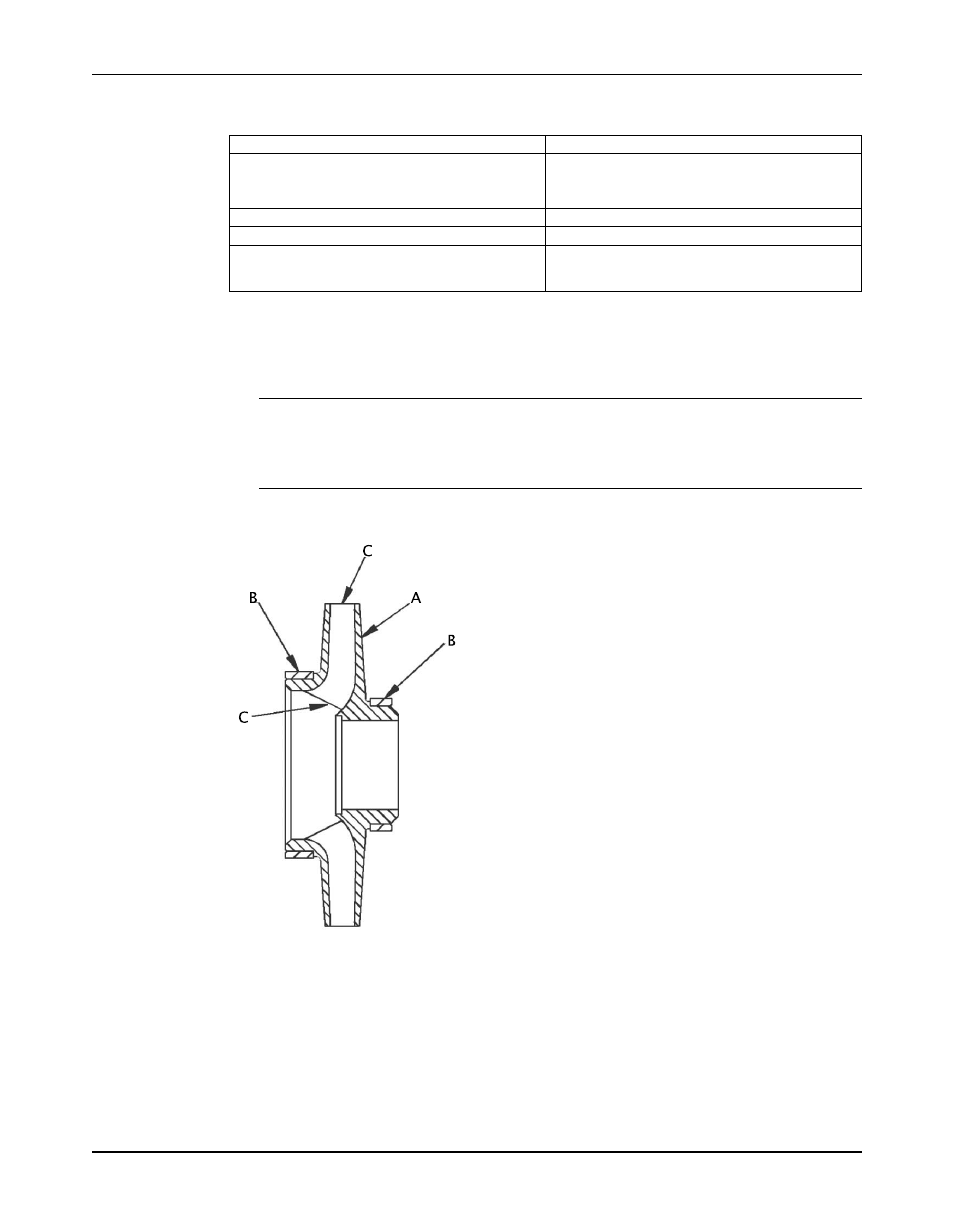

Impeller areas to inspect

A. Shroud

B. Wear ring

C. Vane

Oil ring replacement

Oil rings must be as round as possible in order to function properly. Replace oil rings if they are

worn, distorted, or damaged beyond reasonable repair.

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual

69