Nameplate information – Goulds Pumps 3600 - IOM User Manual

Page 16

Product Description

• Constant-level oilers and labyrinth seals are standard.

• No machining is required to convert the standard ring oil lube to either purge-oil or pure-oil

mist (pure-oil mist applications require minor bearing housing modifications).

• Pressure lubrication is required with hydrodynamic thrust bearings.

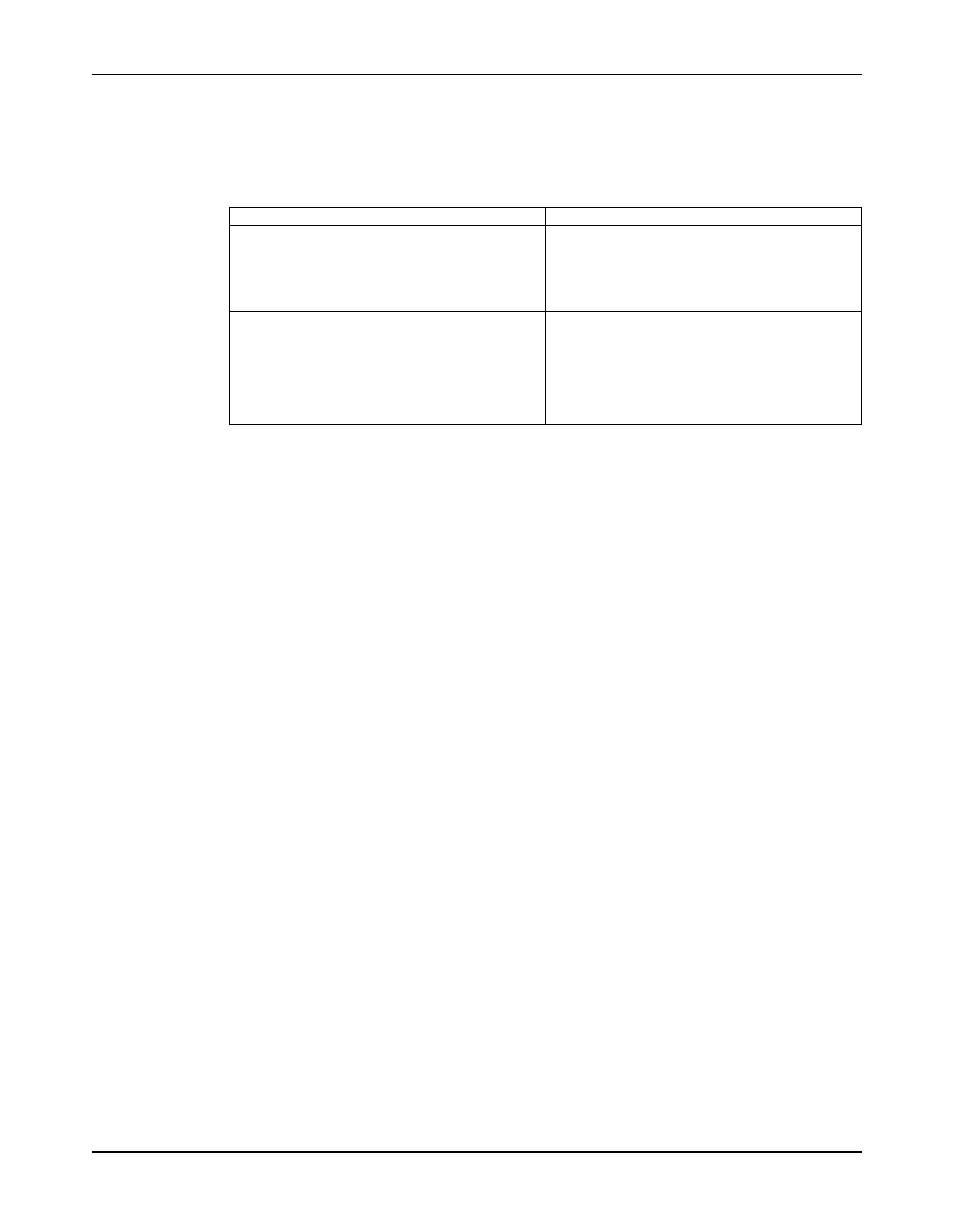

Bearings

Bearing type

Characteristics

Inboard (radial)

• Consists of a single-row deep-groove ball

bearing (standard)

• Carries only radial load

• Optional sleeve bearings (standard for size

6x8-13 pumps)

Outboard (thrust)

• Consists of a pair of single-row angular contact

ball bearings mounted back-to-back (standard)

• Shouldered and locked into place, enabling the

bearing to carry both radial and axial thrust

loads

• Optional hydrodynamic thrust bearing (used

with sleeve-type journal bearings)

Shaft

The heavy-duty shaft has the following characteristics:

• Designed for cartridge mechanical seals

• Minimal shaft deflection at the seal faces (0.002) when run in the worst-case condition

(typically minimum flow)

• Critical speed at least 20% above design operating speed

• Fully compliant with API 10th Edition (ISO 13709)

Baseplate

The fabricated steel baseplate supports the pump, driver, and accessories in accordance with

API-610 10th Edition (ISO 13709) requirements.

Direction of rotation

The shaft rotates counterclockwise when viewed from the power end.

Intended applications

Model 3600 is designed to meet the rigorous demands of the petroleum and petrochemical

industry.

Nameplate information

Important information for ordering

Every pump has a nameplate that provides information about the pump. The nameplate is

located on the pump casing.

When you order spare parts, identify this pump information:

• Model

• Size

• Serial number

• Item numbers of the required parts

Refer to the nameplate on the pump casing for most of the information. See Parts List for item

numbers.

14

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual