Coupling guard assembly, Install the coupling guard – Goulds Pumps 3600 - IOM User Manual

Page 37

Commissioning, Startup, Operation, and Shutdown

Coupling guard assembly

Precautions

WARNING:

• Never operate the pump without the coupling guard correctly installed.

• Avoid death or serious injury. Assure mechanical seal guard is properly installed using supplied

fastening hardware.

• Always disconnect and lock out power to the driver before you perform any installation or

maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical

injury.

• Electrical connections must be made by certified electricians in compliance with all international,

national, state, and local rules.

• Refer to driver/coupling/gear manufacturers installation and operation manuals (IOM) for specific

instructions and recommendations.

• The coupling used in an Ex-classified environment must be properly certified and must be

constructed from a non-sparking material.

•

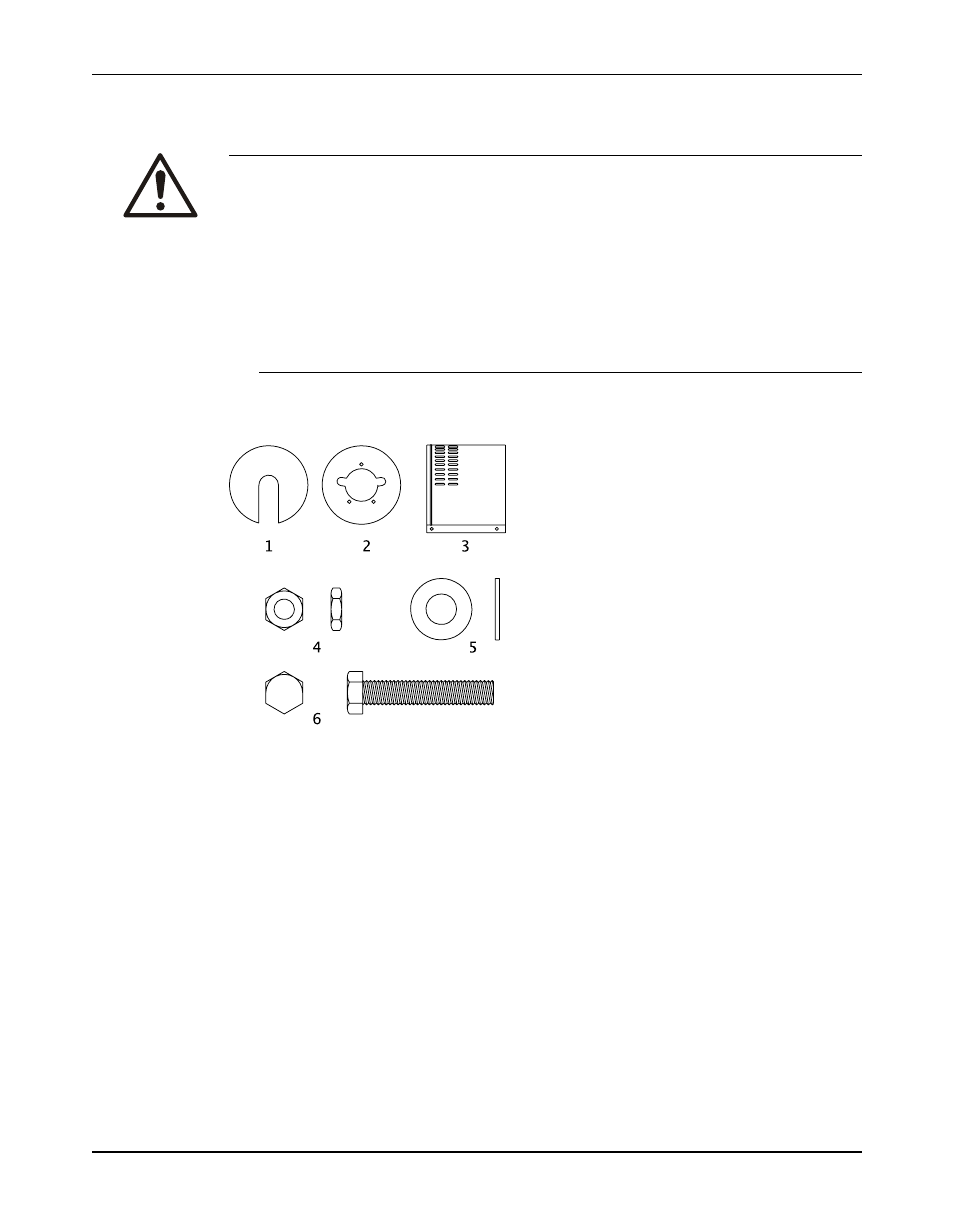

Required parts

These parts are required:

1. End plate, drive end

2. End plate, pump end

3. Guard half, 2 required

4. 3/8-16 nut, 3 required

5. 3/8 in. washer

6. 3/8-16 x 2 in. hex head bolt, 3 required

Install the coupling guard

1. Is the end plate (pump end) already installed?

• If yes: Make any necessary coupling adjustments and then proceed to step 2.

• If no: Complete these steps:

a) Remove the spacer portion of the coupling.

Refer to the instructions from the coupling manufacturer for assistance.

b) If the coupling hub diameter is larger than the diameter of the opening in the end plate,

then remove the coupling hub.

c) Remove the thrust bearing end-cover screws.

d) Align the end plate to the thrust bearing end cover so that the holes in the end plate

align with the holes in the end cover.

e) Replace the three thrust bearing end cover screws and torque to the values shown in

the Maximum torque values for fasteners table.

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual

35