Goulds Pumps 3600 - IOM User Manual

Page 75

Maintenance

a) Clean the wear-ring seats thoroughly to make sure that they are smooth and free of

scratches.

b) Heat the new impeller wear rings to 180°F–200°F (82°C–93°C) using a uniform method

for heating, such as an oven, and place them on the impeller (101-101M) wear-ring

seats.

CAUTION:

Wear insulated gloves when you handle rings. Rings will be hot and can cause physical injury.

c) Tack weld each ring in place in three equidistant places.

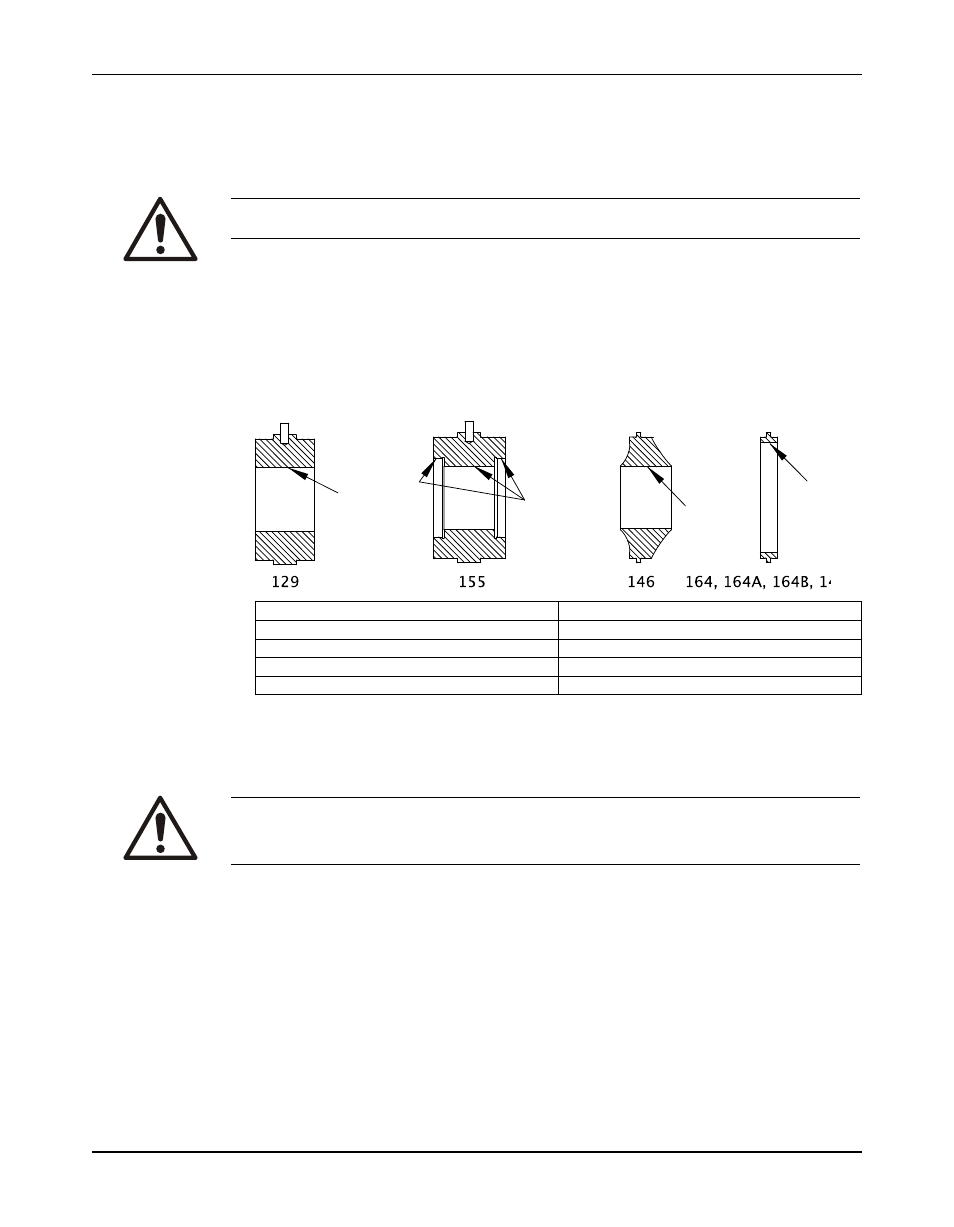

3. Check the throttle bushing (129), the center bushing (155), the diaphragm (146), the case

ring (164, 164A, 164B), and the stage ring (144) runout/distortion by measuring the bore at

three locations with inside micrometers or vernier calipers.

Correct any distortion in excess of 0.003 in. (0.076 mm) by machining prior to trimming new

impeller wear rings, if supplied.

The arrows point to wear surfaces on these parts.

Part number

Part name

129

Throttle bushing

155

Center bushing

146

Diaphragm

164, 164A, 164B, 144

Case and stage ring

4. Confirm the bore of the throttle bushing (129), the center bushing (155), the diaphragm

(146), the casing ring (164, 164A, 164B), and the stage ring (144).

5. Turn the impeller wear rings (202, 202A, 202B, 203) to size after mounting on the impeller

(101-101M).

CAUTION:

The impeller and wear-ring clearance setting procedures must be followed. Improperly setting the

clearance or not following any of the proper procedures can result in sparks, unexpected heat

generation, and equipment damage.

All replacement impeller wear rings are supplied 0.020 in. to 0.030 in. (0.508 mm to 0.762

mm) oversize. See Minimum running clearances for final running clearances. Machine the

impeller rings accordingly.

When the impeller assembly is supplied as a spare part (impeller with wear rings), the wear

rings are machined to the required dimension.

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual

73