Final piping checklist – Goulds Pumps 3600 - IOM User Manual

Page 33

Installation

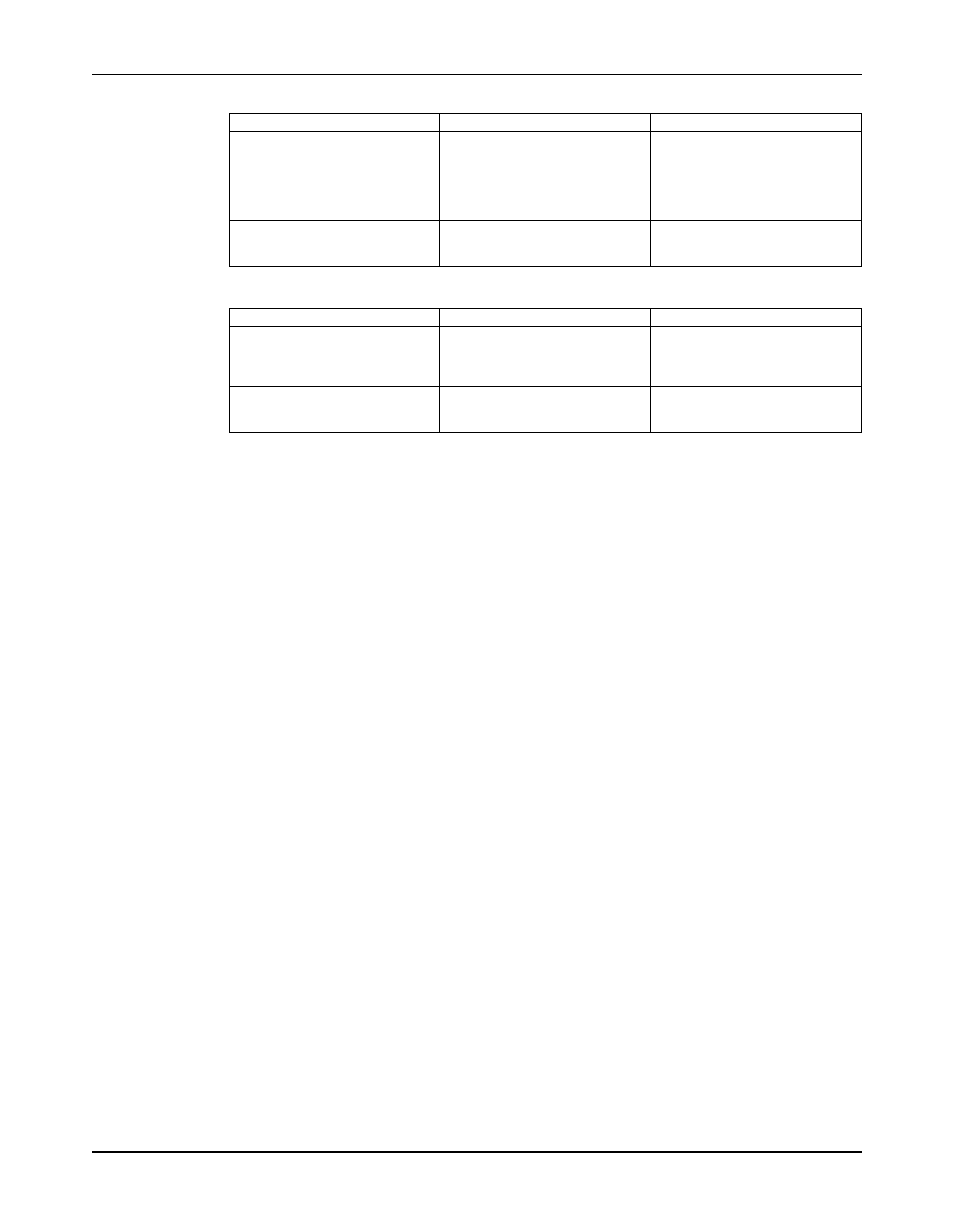

Checklist

Check

Explanation/comment

Checked

Check that the minimum flow for

–

each component is 1 gpm (4 lpm).

If the bearing and seal chamber

cover cooling are provided, then

the auxiliary piping must flow at 2

gpm (8 lpm).

Check that the cooling water pres- –

sure does not exceed 100 psig

(7.0 kg/cm

2

).

Final piping checklist

Check

Explanation/comment

Checked

Check that the shaft rotates

Rotate the shaft by hand. Make

smoothly.

sure there is no rubbing that can

lead to excess heat generation or

sparks.

Re-check the alignment to make

If pipe strain exists, then correct

sure that pipe strain has not

the piping.

caused any misalignment.

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual

31

See also other documents in the category Goulds Pumps Pumps:

- 3100 - IOM (52 pages)

- 3171 - IOM (60 pages)

- 3180-86 - IOM (158 pages)

- 3189 - IOM (32 pages)

- 3196 - IOM (148 pages)

- 3196 i-FRAME - IOM (152 pages)

- 3198 i-FRAME - IOM (126 pages)

- 3296 EZMAG - IOM (96 pages)

- 3296M - IOM (92 pages)

- 3298 - IOM (120 pages)

- 3311 - IOM (44 pages)

- 3316 - IOM (36 pages)

- 3335 - IOM (40 pages)

- 3355 - IOM (66 pages)

- 3393 - IOM (124 pages)

- 3408 - IOM (78 pages)

- 3408A - IOM (44 pages)

- 3409 - IOM (68 pages)

- 3410 - IOM (56 pages)

- 3420 - IOM (120 pages)

- 3498 - IOM (59 pages)

- 3500XD - IOM (44 pages)

- 3501 Mixer - IOM (48 pages)

- 3610 - IOM (98 pages)

- 3620 - IOM (98 pages)

- 3640 - IOM (98 pages)

- 3642 - IOM (12 pages)

- 3675 - IOM (12 pages)

- 3700 - IOM (110 pages)

- 3755 - IOM (32 pages)

- 3796 i-FRAME - IOM (134 pages)

- 3910 11th ed. - IOM (80 pages)

- 3935 - IOM (24 pages)

- 3996 - IOM (52 pages)

- 4550 - IOM (36 pages)

- 5000 - IOM (24 pages)

- 5100 - IOM (28 pages)

- 5150 - IOM (28 pages)

- 7200CB - IOM (132 pages)

- ANSI FAMILY IOM (ATEX Compliant) (56 pages)

- ANSI FAMILY IOM (ATEX Compliant) (27 pages)

- ANSI FAMILY IOM (ATEX Compliant) (42 pages)

- ANSI FAMILY IOM (ATEX Compliant) (45 pages)

- Pump Safety (9 pages)