Goulds Pumps 3600 - IOM User Manual

Page 77

Maintenance

NOTICE:

Make sure that all parts and threads are clean and that you have followed all directions under

the Preassembly inspections section.

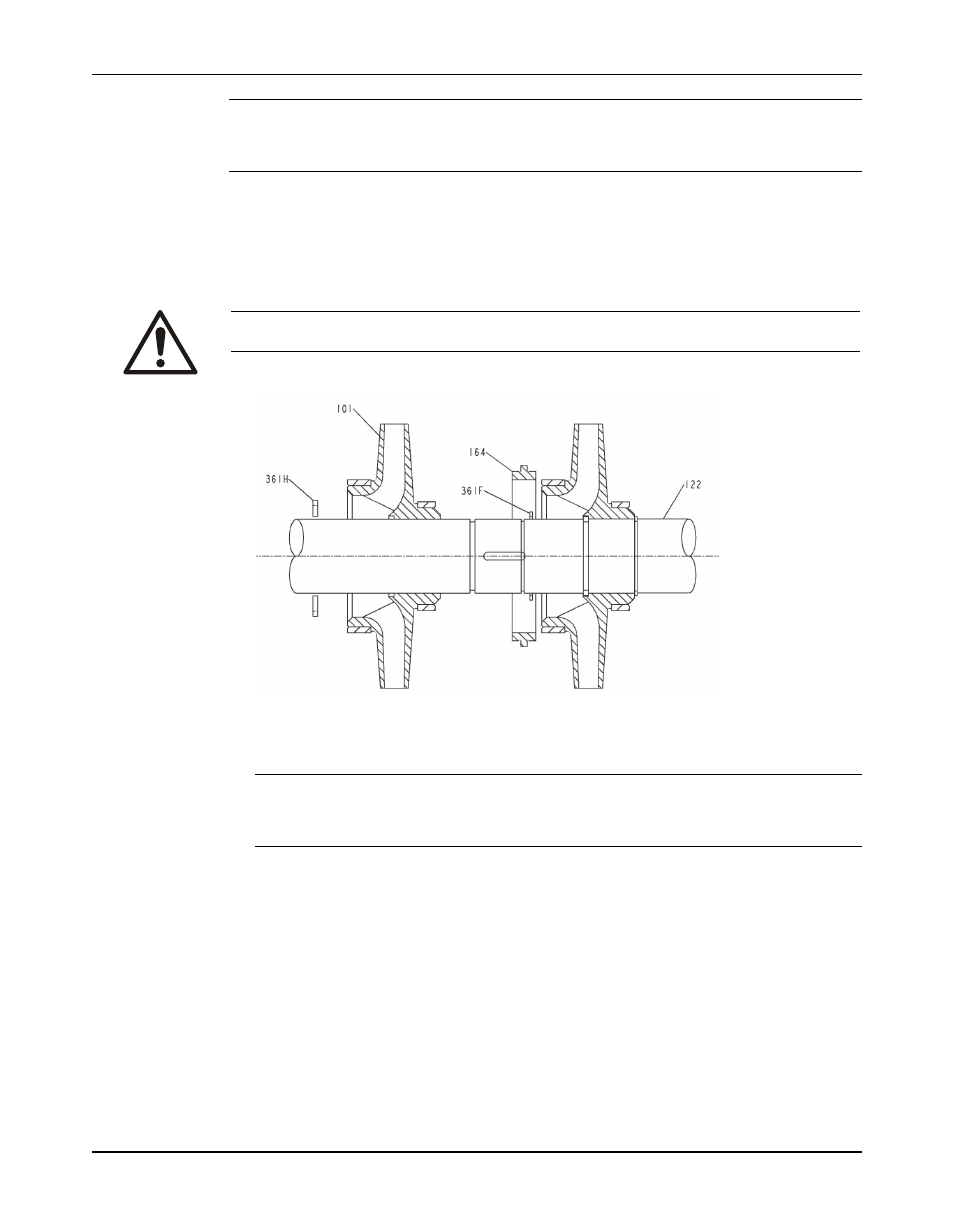

1. Assemble the center impeller (101M) onto the shaft. The impeller is interference fit.

a) Use an electric induction heater to preheat the impeller to 300°F–400°F

(150°C–200°C).

b) Slide the impeller past the locating ring groove, put the locating rings (361H) in place,

and slide the impeller back so that it is snug against the locating ring.

c) Install the snap ring (361F).

CAUTION:

Burn hazard. The impeller will get hot. Wear insulated gloves when handling the impeller.

2. Install the center sleeve (205). (Not applicable on 6x8-13 pumps.)

3. Repeat step 1 for all subsequent impellers making sure to install the casing ring (164,

164A, 164B) on each previous impeller.

NOTICE:

Allow the shaft and impeller to cool to ambient temperature before assembling the next

impeller.

4. On double-suction pumps only, prior to assembling the first-stage impeller (101), assemble

the diaphragm sleeve (204):

a) Slide the diaphragm sleeve onto the shaft past the locating ring groove, put the locating

ring (361H) in place, and slide the sleeve back so that it is snug against the locating

ring.

Model 3600, API 610 8th, 9th, 10th & 11th Editions (ISO 13709) Installation, Operation, and Maintenance Manual

75