Decpnt, T base, Sclfac – Red Lion PAX2S User Manual

Page 21: Lo cut, Disply, Pwrup, Totalizer (integrator) parameters ( total )

21

dECPNt

0.000

tOt

t bASE

MIN

tOt

SCLFAC

1.000

tOt

Lo Cut

-1999.99

tOt

Decimal

Point

Time Base

Scale Factor

Low Cut

Value

dISPLY

tOtAL

PWrUP

N0

tOt

Power Up

Reset

Pro

dISPLY

Pro

NO

F1

F2

P

D

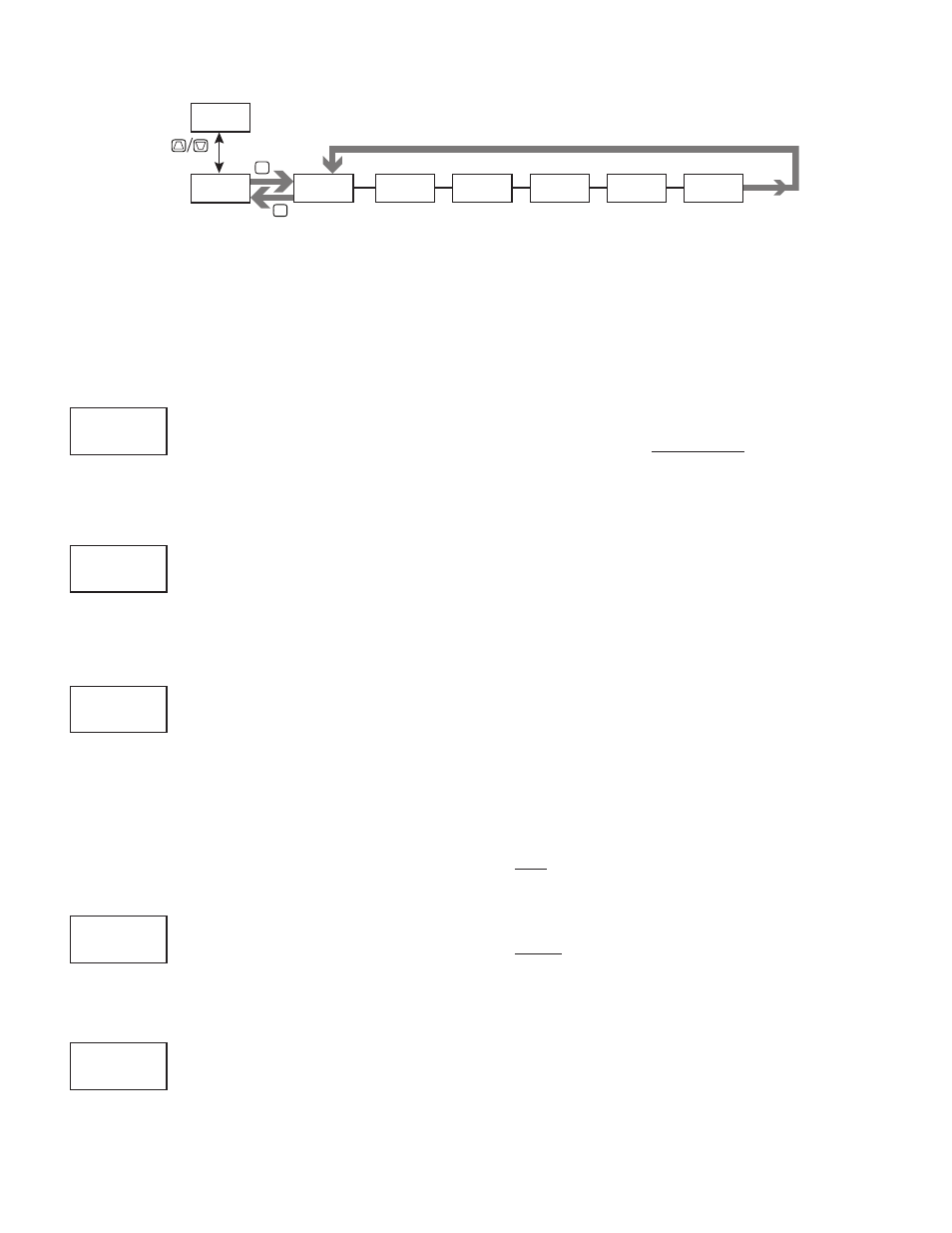

TOTALIZER (INTEGRATOR) PARAMETERS (tOtAL)

The totalizer accumulates (integrates) the Relative Input Display value using

one of two modes. The first is using a time base. This can be used to provide an

indication of total flow, usage or consumption over time. The second is through

a user input or function key programmed for Batch (one time add on demand).

This can be used to provide a readout of total weight, useful in weight based

filling operations. If the Totalizer is not needed, its display can be locked-out and

this module can be skipped during programming.

TOTALIZER DECIMAL POINT

0

0.0

0.00

0.000

0.0000

For most applications, this should match the Input Display Decimal Point

(dECPNt). If a different location is desired, refer to Totalizer Scale Factor.

TOTALIZER TIME BASE

SEC

-seconds (/1)

MIN

-minutes (/60)

hour

-hours (/3600)

dAY

-days (/86400)

This is the time base used in Totalizer accumulations. If the Totalizer is being

accumulated through a user input programmed for Batch, then this parameter

does not apply.

TOTALIZER SCALE FACTOR

0.001

to

65.000

For most applications, the Totalizer reflects the same decimal point location

and engineering units as the Input Display. In this case, the Totalizer Scale

Factor is 1.000. The Totalizer Scale Factor can be used to scale the Totalizer to

a value that is different than the Input Display. Common possibilities are:

1. Changing decimal point location (example tenths to whole)

2. Average over a controlled time frame.

Details on calculating the scale factor are shown later.

If the Totalizer is being accumulated through a user input programmed for

Batch, then this parameter does not apply.

TOTALIZER LOW CUT VALUE

-199999

to

999999

A low cut value disables Totalizer when the Input Display value falls below

the value programmed.

TOTALIZER POWER UP RESET

NO

-

do not reset buffer

YES

-

reset buffer

The Totalizer can be reset to zero on each meter power-up by setting this

parameter to YES.

TOTALIZER BATCHING

The Totalizer Time Base is overridden when a user input or function key is

programmed for store batch (bAt). In this mode, when the user input or function

key is activated, the Input Display reading is multiplied by the totalizer scale

factor and then one time added to the Totalizer (batch). The Totalizer retains a

running sum of each batch operation until the Totalizer is reset. This is useful in

weighing operations, when the value to be added is not based on time but after

a filling event.

TOTALIZER USING TIME BASE

Totalizer accumulates as defined by:

Totalizer Scale Factor = Totalizer Display*

Input Display*

*Value indicated with decimal and all display units after the decimal; Prior to

calculating, “drop” the decimal point leaving all trailing units.

Where:

Input Display = Fixed Input Display value.

Totalizer Display = Totalized value with Input Display constant during a

period of time equal to the Totalizer Time Base.

Example: A PAX2S is monitoring the total weight of material on a 20 ft

conveyor. The conveyor operates at a constant rate of 1 ft/sec. The Totalizer

will calculate the total weight of material output from the conveyor. Although

the PAX2S Input Display indicates lbs in whole units, the Totalizer will be

programmed to display tons in 1/10 units. Note that this application requires

a User Input to enable the Totalizer when the conveyor is running. Accuracy

is dependent on the amount of material and position of material still on the

conveyor. For accurate totalizer reading, the conveyor should be allowed to

“empty” before taking a totalizer reading.

There are several factors to consider in this example. First, the material that

clears the end of the conveyor in 1 second is only 1/20 of the weight being

displayed at any given time (20 ft conveyor @ 1 ft/sec). Second, the Totalizer

display is in tenths of tons, while the input is in pounds.

In order to calculate the Totalizer Scale Factor, choose a constant Input

Display (100) value and then determine the Totalizer Display value that

would result after the period of the Totalizer Time Base (1 hour) selected.

100 lb = 5 lb/sec. → With 100 lb on the conveyor, 5 lbs falls off

20 sec the end of the conveyor each second.

5 lb/sec x 3600 sec = 18,000 lb → 3600 seconds of material passing the end

of the conveyor in an hour.

18,000 lb = 9.0 tons → Conversion of lbs to tons.

2000 lb

Conclusion: Input Display of 100 results in a Totalizer Display of 9.0 after 1

hour of constant and continuous operation. Place these values in the Totalizer

Scale Factor formula as follows:

Totalizer Scale Factor = Totalizer Display* / Input Display*

Totalizer Scale Factor = 9.0/100

Totalizer Scale Factor = 90/100 **

Totalizer Scale Factor = 0.9

* This value should include the decimal and all display units after the decimal.

** This step requires that the decimal be “dropped”, but all other digits remain.

dECPNt

0.000

tOt

t bASE

MIN

tOt

SCLFAC

1.000

tOt

Lo Cut

-1999.99

tOt

PWrUP

NO

tOt