Profibus technology and protocol, 1 overview /protocol architecture, 2 profibus dp device types – NORD Drivesystems BU0020 User Manual

Page 47: Overview /protocol architecture, Profibus dp device types, Table 7: iso/osi layer model, 5 profibus technology and protocol

5 PROFIBUS technology and protocol

BU 0020 GB-2612

47

5. PROFIBUS technology and protocol

The PROFIBUS (Process Field Bus) is the fastest standardised (open) bus system for field use. This

technology enables consistent communication down to the lowest field level and is widely used in

production, process and building automation systems. Profibus was developed by SIEMENS and the

Profibus users' organisation and was standardised in the international standard IEC 61158. Profibus is

a multi-master system and therefore enables the joint operation of several automation, engineering or

visualisation systems with decentralised peripheral devices on a common field bus. The protocol

describes the process rules for the transfer of data. The protocol specifies both the format of

messages as well as the flow of data in data transfer. A wide range of field devices can be networked

without problems, and in case of failure of individual field devices, data transfer to the remaining bus

participants continues without interruption.

The system configuration or bus structure can be planned and implemented both as a mono-master

system (only one master) and as a multi-master system (several masters).

Pos: 57 /Anleitungen/Bussysteme/4. Protokoll/Profibus [BU0020]Übersicht / Protokollarchitektur @ 1\mod_1335521150251_388.docx @ 24457 @ 2 @ 1

5.1 Overview /Protocol architecture

The ISO/OSI layer model describes the communication between the individual participants (slaves) of

a communication or automation system. Of the seven defined OSI layers, PROFIBUS uses layers 1, 2

and 7. PROFIBUS DP only uses layers 1 and 2 and the DP user interface.

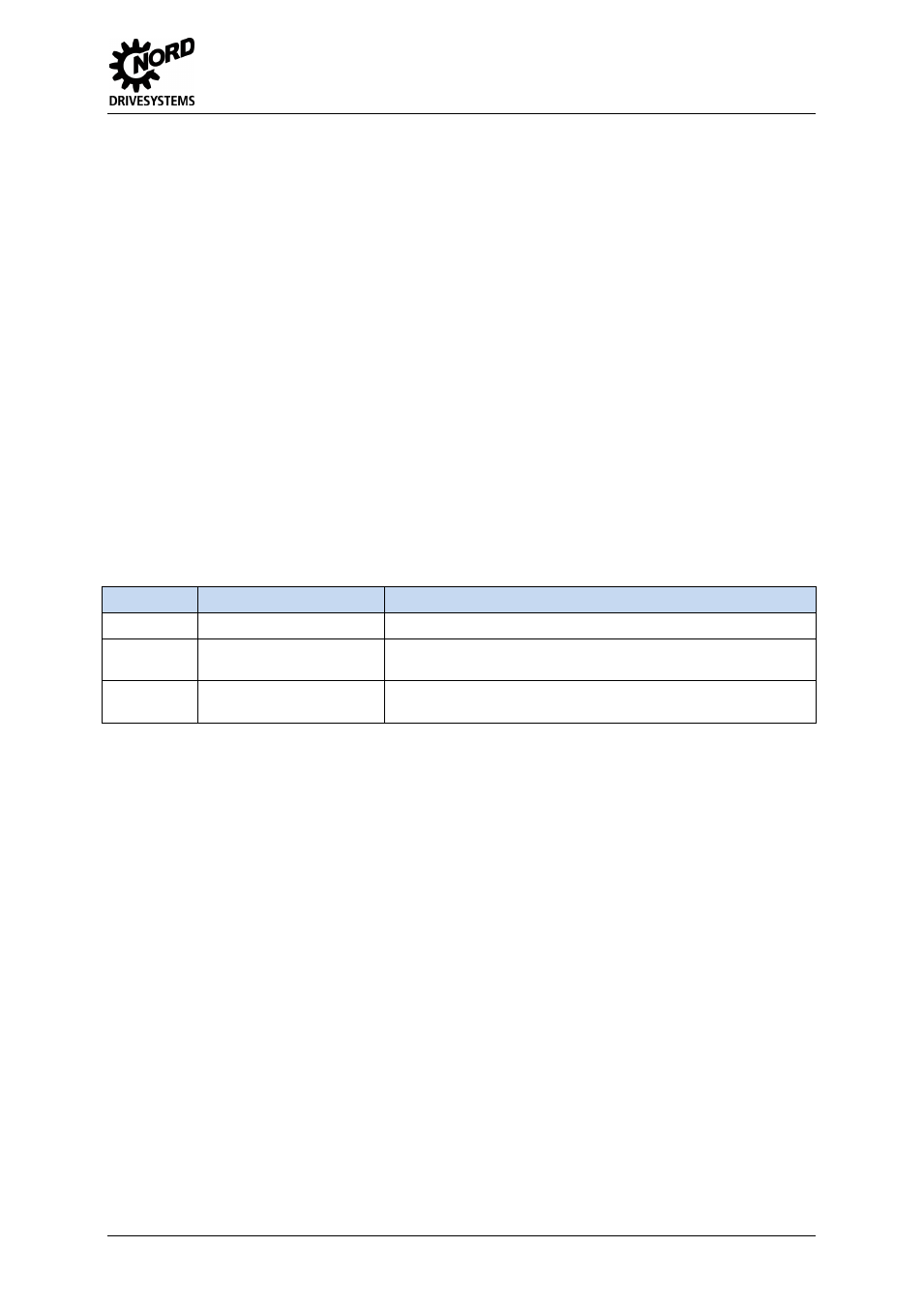

Layer

Type

Meaning

1

Physical layer

defines the hardware, coding, speed etc. of data transfer

2

Connection layer

describes the bus access procedure including data security, i.e. it

defines the physics of transfer

7

Application layer

defines the interface to the application program with the

application-orientated commands.

Table 7: ISO/OSI Layer model

Layer 2 of the ISO/OSI model includes

•

the general format for data transfer telegrams

•

the bus access mechanisms

•

the security mechanisms

•

the times to be complied with

•

possible transfer services.

The user only has a slight influence on the design of layer 2, as almost all services are included in the

available PROFIBUS ASICs.

Pos: 58 /Anleitungen/Bussysteme/4. Protokoll/Profibus [BU0020]Gerätetypen PROFIBUS DP @ 1\mod_1335521632362_388.docx @ 24481 @ 2 @ 1

5.2 PROFIBUS DP device types

PROFIBUS DP is an acronym for "Process Field Bus for Decentralised Peripherals" i.e. for the simple,

rapid, cyclic and deterministic exchange of process data between a PROFIBUS master and the

assigned PROFIBUS slaves connected to the field bus. The exchange of process data takes place

between central automation devices such as PLCs, PCs or process control systems and decentralised

field devices such as drive units, valves, analysis devices and frequency inverters. Exchange of

process data is mainly carried out cyclically between the PROFIBUS participants (master ↔ slaves).

The DP communication protocol is categorised into three basic functions or performance levels, DP-

V0, DP-V1 and DP-V2.