Remote maintenance (in preparation), Configuration example, Table 4: configuration example - devices used – NORD Drivesystems BU2200 User Manual

Page 10: Attention, 3 configuration in the bus system, 3 remote maintenance (in preparation), Remote control via nordcon, Unauthorised access, 4 configuration example

3 Configuration in the Bus System

10

BU 2200 GB-3813

3.3 Remote Maintenance (in preparation)

With the aid of the NORDCON software it is possible to access the module and the underlying

frequency inverter via Ethernet for maintenance purposes.

The access rights for remote maintenance are assigned with DIP switch and range from "read only

parameter" (default) to "reading and writing access of parameters" and "remote control of the drive

unit".

(For details, please refer to the "Technical Information / Data Sheet for the bus module).

Pos : 26 /Anl eitungen/ Elektroni k/ Bus s yst eme/3a. Konfiguration i m Buss yst em/ Ergänzung z u F ernwart ung [Et hernet Buss ys teme allgemei n] @ 4\ mod_1378711913223_388. doc x @ 93711 @ @ 1

ATTENTION

Remote control via NORDCON

For control via NORDCON it is important to set parameter P513 "Telegram timeout" according to the NORDCON

cycle time. This ensures that the frequency inverter triggers an error if the Ethernet connection fails!

ATTENTION

Unauthorised access

Although the possibility of remote maintenance facilitates the control and analysis of the devices in case of faults,

on the other hand it entails the danger of a "cyber attack" on the system.

The provision of suitable protection measures against unauthorised access is the responsibility of the constructor

of the system. They are not the responsibility of Getriebebau NORD!

Pos : 27 /Anl eitungen/ Elektroni k/ Bus s yst eme/3a. Konfiguration i m Buss yst emKonfigur ati ons beispi el Syst embus mi t Bus baugruppe und FU [ allgemein] @ 4\ mod_1379500233214_388. doc x @ 99186 @ 2 @ 1

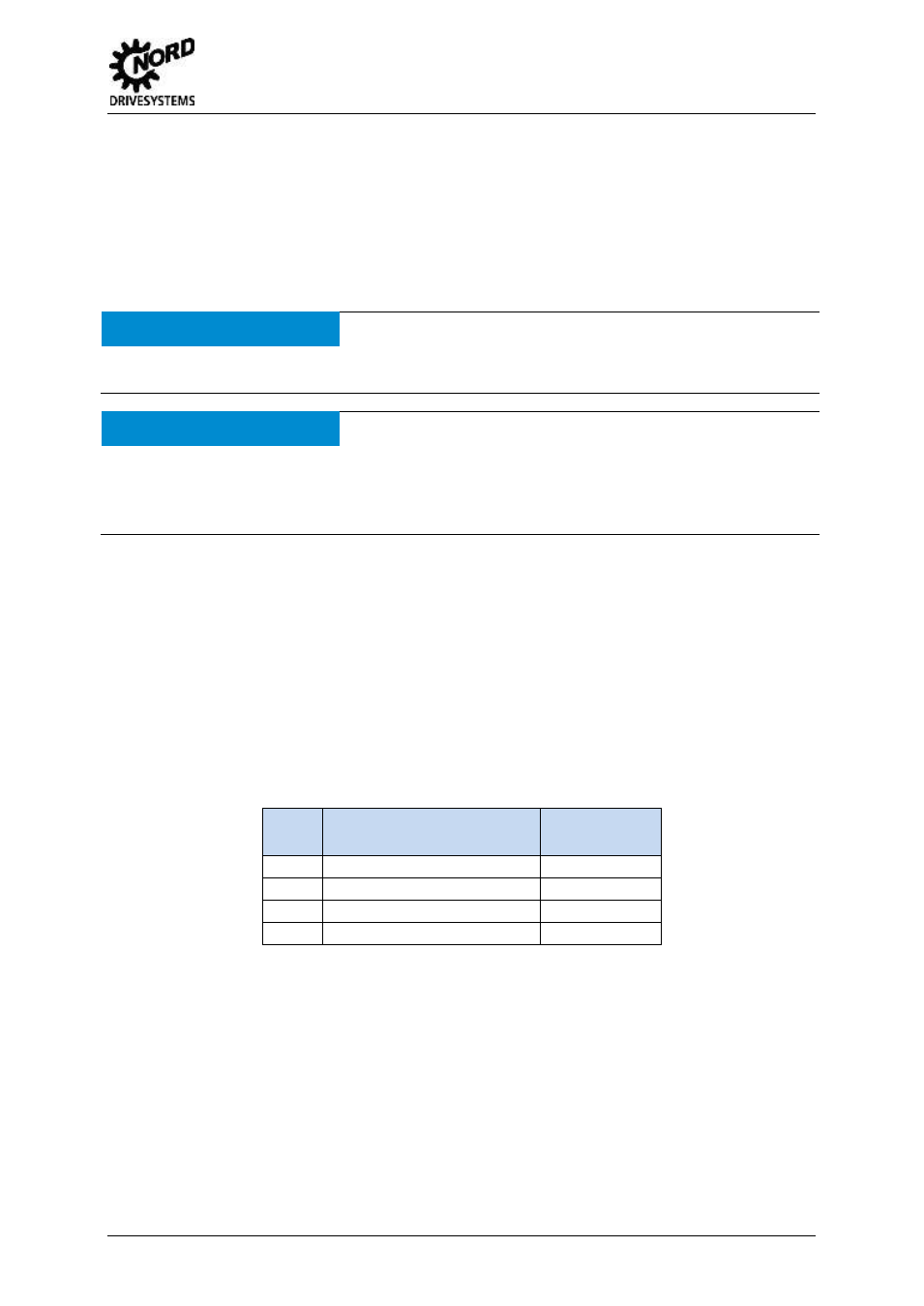

3.4 Configuration example

The example described below serves for orientation when commissioning a network consisting of a

bus module and frequency inverters. The most important commissioning stages are listed, which are

necessary to set up the exchange of data on the process data level.

Settings specific to the application (motor data, speed control, control terminal functions etc.) cannot of

course be described here.

Brief description

Via a bus module, 3 frequency inverters are to be independently controlled with a single speed.

The following devices are used:

Serial

No.

Frequency inverter type

Designation

1

SK 2x5E frequency inverter

FI 1

2

SK 2x5E frequency inverter

FI 2

3

SK 2x5E frequency inverter

FI 3

4

SK xU4-

… (bus module)

Bus module

Table 4: Configuration example - Devices used

The bus module and FI 3 should always be the last physical participants on the system bus.