Operating limits, Eseer calculations, Glycol data – Airedale DeltaChill FreeCool 110kW - 1080kW User Manual

Page 24: Deltachill ™ chillers

DELTACHILL

™

Chillers

24

Chillers

Technical Manual : 7022932_V1.9_11/2013

Operating Limits

(For 100% Water)

Unit with Electronic Fan Speed HP Control (-20°C)

Minimum Ambient Air DB °C

-20°C

Maximum Ambient Air DB °C

Refer to

Performance Data

– Capacity Data

Minimum Leaving Water Temperature °C

+5°C and+6°C (DCC and DCF respectively)

Maximum Return Water Temperature °C

+18°C and+20°C (DCC and DCF respectively)

1

Temperatures lower than those stated can be obtained with the addition of glycol.

2

For conditions outside those quoted, please refer to Airedale.

ESEER Calculations

The quoted EER figures cover the performance of the unit ONLY at the standard rating

conditions of 7/12°C water, 35°C ambient. The ESEER calculation method has been

developed by Eurovent to give a single value that is a realistic indication of the efficiency

of the Chiller across the year round range of operation.

The ESEER value is calculated from the unit’s performance at 20, 25, 30 and 35°C

ambient temperatures for all loading stages, and with a fixed 7°C supply temperature. All

calculations assume the system operates with 100% water.

ESEER = 0.03.EER

100%

+ 0.33.EER

75%

+ 0.41.EER

50%

+ 0.23.EER

25%

Where 0.03, 0.33, 0.41 and 0.23 are specified weighting factors for use on calculating

ESEER.

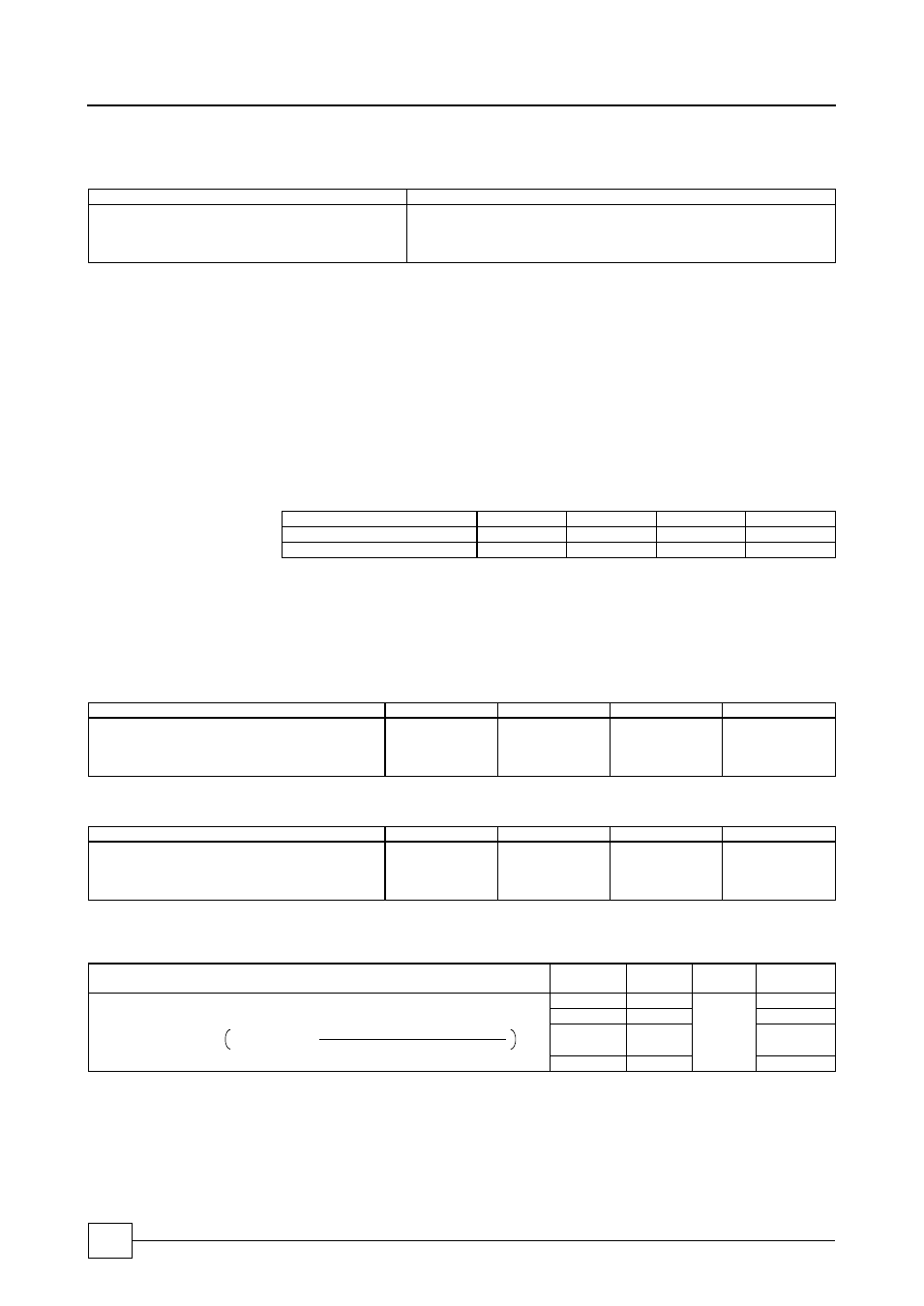

Temperature

35°C

30°C

25°C

20°C

Capacity Requirement

100%

75%

50%

25%

Percentage of Total Hours

0.03

0.33

0.41

0.23

Glycol Data

Glycol is recommended when a supply water temperature of +5°C or below is required or

when static water can be exposed to freezing temperatures.

For a given percentage of glycol in the system there are correction factors that need to

be applied, the following tables can be used as a guide.

Ethylene Glycol Nominal Correction Factors

Glycol in System / Freezing Point ºC

10% / -4°C

20% / -9°C

30% / -15°C

40% / -23°C

Cooling Duty

Catalogue Data x by:

0.98

0.97

0.95

0.93

Input Power

0.99

0.98

0.96

0.95

Water Flow

0.99

1.02

1.04

1.07

Pressure Drop

1.05

1.20

1.38

1.57

Propylene Glycol Nominal Correction Factors

Glycol in System / Freezing Point ºC

10% / -2°C

20% / -6°C

30% / -12°C

40% / -20°C

Cooling Duty

Catalogue Data x by:

0.97

0.95

0.91

0.88

Input Power

0.99

0.98

0.96

0.95

Water Flow

0.98

0.97

0.95

0.95

Pressure Drop

1.08

1.17

1.31

1.45

Example

DCC033DR-08BMM0

operating at 7/12, 35°C Ambient, 20% Ethylene Glycol, with AC

condenser fans.

Catalogue

Figure Multiplier

Corrected

Figure

Cooling kW

(refer to

Performance Data

– Capacity Data

)

326

x 0.97

20%

Ethylene

Glycol =

316.2 kW

Input kW

(refer to

Performance Data

– Capacity Data

)

105.6

x 0.98

103.5 kW

Flow l/s

calculated

(DX (Mechanical Cooling kW)

15.56 l/s

x 1.02

15.87 l/s

T x 4.19

Pressure Drop kPa

(refer to

TBA kPa

x 1.20

TBA kPa