7 second pid parameter set 25, 7 second pid parameter set, Parameter adjustment effects – West Control Solutions N8840 User Manual

Page 25: Formulas

3.7 Second PID parameter set

The process characteristic is frequently affected by various factors such as

process value, correcting variable and material differences.

To comply with these requirements, the 8840 profiler can be switched over

between two parameter sets.

Parameter sets PArA and PAr.2 are provided for heating and cooling.

Dependent of configuration ( ConF/LOG/Pid.2), switch-over to the second

parameter set ( ConF/LOG/Pid.2) is via one of digital inputs di1, di2, di3,

key è or interface (OPTION).

g

Self-tuning is always done using the active parameter set, i.e. the second

parameter set must be active for optimizing.

Operation

8840 profiler

25

Second PID parameter set

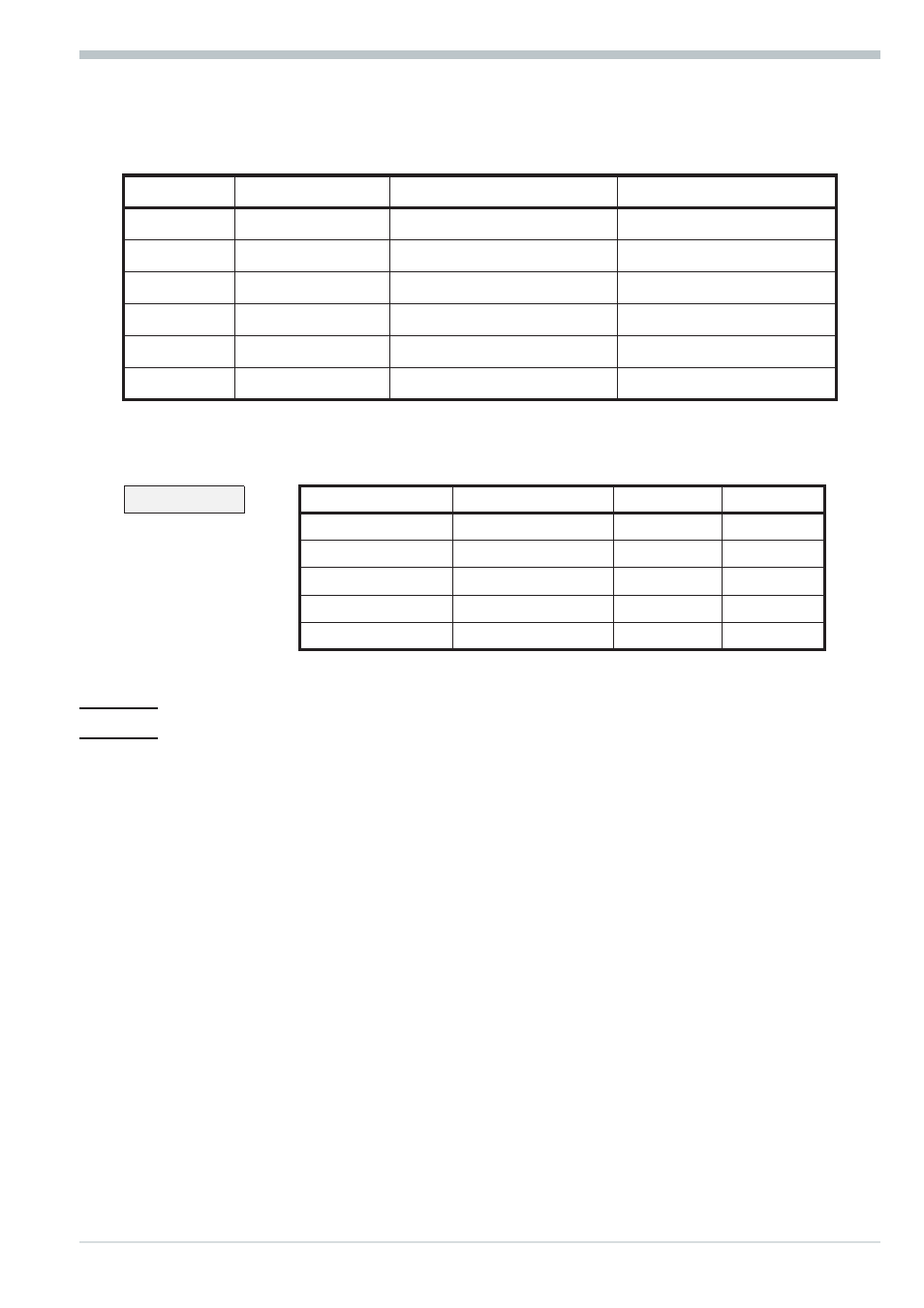

Parameter adjustment effects

Parameter

Control

Line-out of disturbances

Start-up behaviour

Pb1 higher increased damping slower line-out

slower reduction of duty cycle

lower reduced damping

faster line-out

faster reduction of duty cycle

td1 higher reduced damping

faster response to disturbances faster reduction of duty cycle

lower increased damping slower response to disturbances slower reduction of duty cycle

ti1 higher increased damping slower line-out

slower reduction of duty cycle

lower reduced damping

faster line-out

faster reduction of duty cycle

Formulas

K = Vmax * Tu

controller behavior

Pb1 [phy. units]

td1 [s]

ti1 [s]

With 2-point and

3-point controllers,

the cycle time must be

adjusted to

t1 / t2 ≤ 0,25 * Tu

PID

1,7 * K

2 * Tu

2 * Tu

PD

0,5 * K

Tu

OFF

PI

2,6 * K

OFF

6 * Tu

P

K

OFF

OFF

3-point-stepping

1,7 * K

Tu

2 * Tu