3 selecting the method ( conf / cntr / tune ) 17 – West Control Solutions N8840 User Manual

Page 17

Optimization at the set-point: (see page 18)

For optimizing at the set-point, the controller outputs a disturbance variable to the

process. This is done by changing the output variable shortly. The process value

changed by this pulse is evaluated. The detected process parameters are

converted into control parameters and saved in the controller.

This procedure optimizes the control loop directly at the set-point. The advantage

is in the small control deviation during optimization.

3.5.3 Selecting the method ( ConF/ Cntr/ tunE)

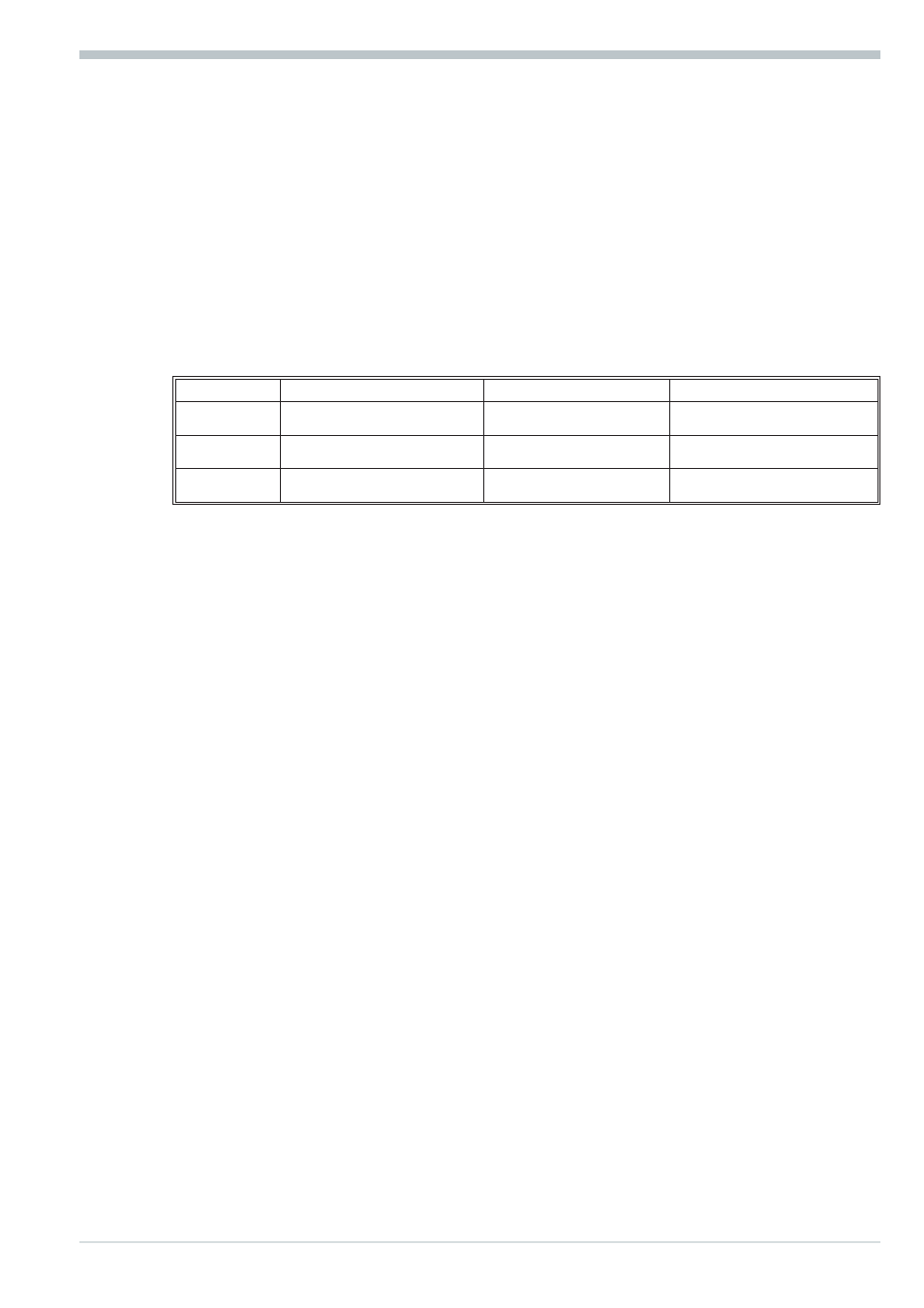

Selection criteria for the optimization method:

Step attempt after start-up

Pulse attempt after start-up Optimization at the set-point

tunE = 0

sufficient set-point reserve is

provided

sufficient set-point reserve is not

provided

tunE = 1

sufficient set-point reserve is

provided

sufficient set-point reserve is not

provided

tunE = 2

always step attempt after

start-up

Sufficient set-point reserve:

inverse controller: (with process value < set-point- (10% of rnGH - rnGL)

direct controller:

(with process value > set-point + (10% of rnGH - rnGL)

Step attempt after start-up

Condition:

- tunE = 0 and sufficient set-point reserve provided or

- tunE = 2

The controller outputs 0% correcting variable or Y.Lo and waits, until the process

is at rest (see start-conditions on page 15).

Subsequently, a correcting variable step change to 100% is output.

The controller attempts to calculate the optimum control parameters from the

process response. If this is done successfully, the optimized parameters are taken

over and used for line-out to the set-point.

With a 3-point controller, this is followed by “cooling”.

After completing the 1st step as described, a correcting variable of -100% (100%

cooling energy) is output from the set-point. After successfull determination of

the “cooling parameters”, line-out to the set-point is using the optimized

parameters.

Operation

8840 profiler

17

Self-tuning