Operation – KROHNE UFM 530 HT EN User Manual

Page 39

OPERATION

6

39

UFM 530 HT

www.krohne.com

12/2013 - 4002393201- HB UFM 530 HT R02 en

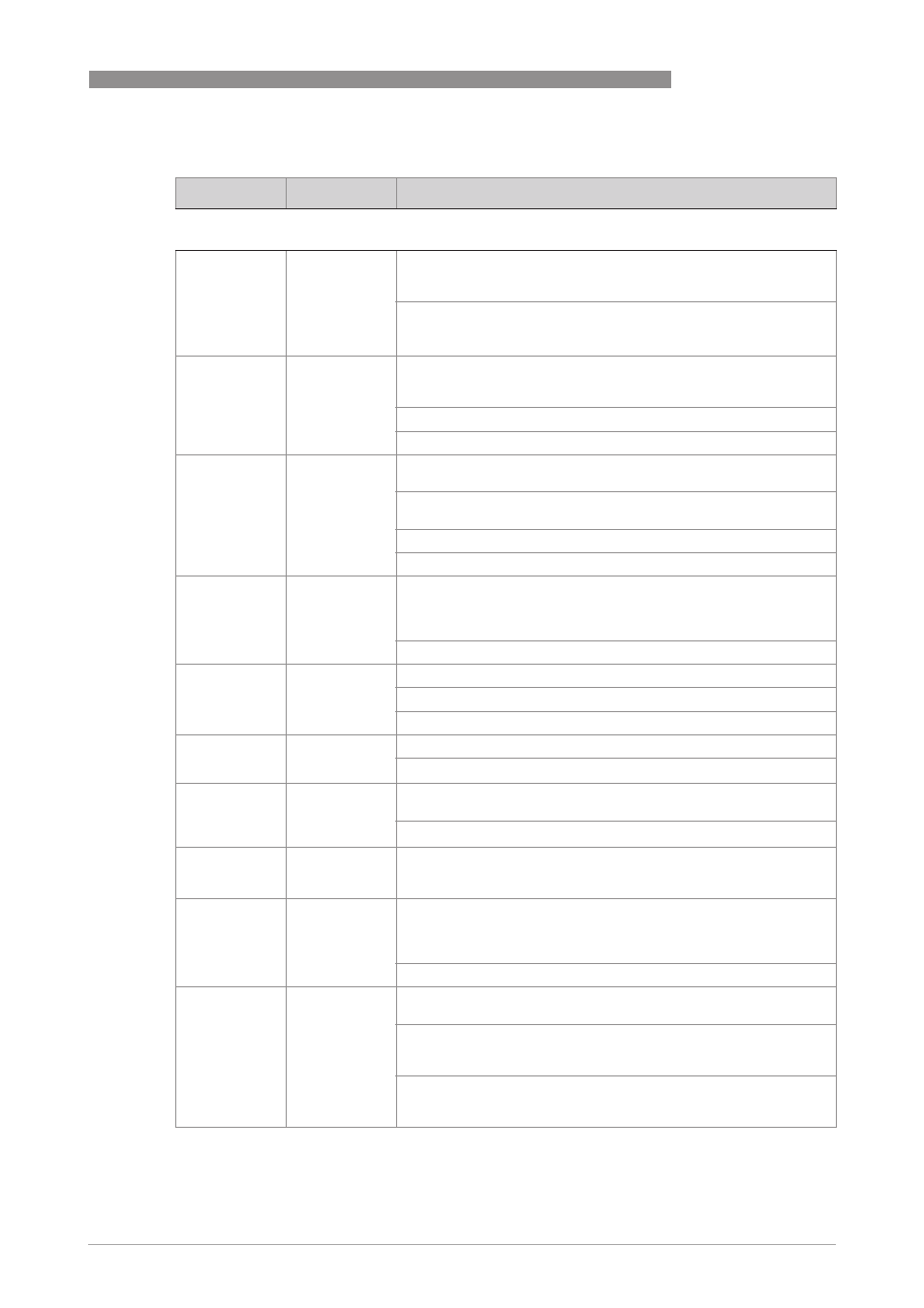

Installation menu

No. of menu

Display text

Setting/description and functions

3.01.00, FLOW (Volume flow parameters)

3.01.01

FULL SCALE

Full-scale value for 100% volume and flow rate units (see

function 1.01.01). The selection of units may be limited to SI units

only.

Available units: m

3

/s, m

3

/min, m

3

/hr, L/s, L/min, L/hr,

US.Gal/s, US.Gal/min, US.Gal/hr, bbls/hr, bbls/day or free user

configurable unit, set by using function 3.07.05...3.07.07).

3.01.02

ZERO VALUE

Although zero calibrated at the factory the flow sensor might still give

an offset flow reading, at "zero" flow in the pipeline. Available

settings:

1) FIXED: factory zero setting.

2) MEASURED: value measured with function 3.01.03 (ZERO CAL).

3.01.03

ZERO CAL

Zero calibration (see function 1.01.03). Note: Carry out only at "zero"

flow and with completely filled measuring tube!

Duration approximately 15s with display

indicating "BUSY":

1) STORE NO: preserve old zero value.

2) STORE YES: store new zero value.

3.01.04

MASTER TC

The master time constant apply for the display and the current and

pulse outputs. It does not apply for totalisation and for the current

output in F/R setting. If required, a different time constant value can

be set for the pulse/frequency output under Function 3.05.06.

Range: 0.02...99.99 s.

3.01.05

LF CUTOFF

Low-flow cut-off for display and outputs.

1) NO: fixed tripping points (ON = 0.1%, OFF = 0.2%).

2) YES: see function 3.01.06 and 3.01.07.

3.01.06

CUTOFF ON

Cut off "active" value.

Range: 1 through 19% of Q

100%

.

3.01.07

CUTOFF OFF

Cut off "de-active" value. Note: value "off" must be greater than value

"on"!

Range: 2 through 20% of Q

100%

.

3.01.08

METER SIZE

The nominal diameter of the measuring tube. See the flow sensor

nameplate. Selection of size from meter size table:

25...3000 mm / 1...120".

3.01.09

GK VALUE

At the factory, each flow sensor is calibrated and supplied with a

calibration constant (GK). This constant can be found on the flow

sensor nameplate and must equal the value on the flow sensor

nameplate.

Range: 0.02...20.

3.01.10

FLOW DIR

The forward flow direction is indicated with an arrow on the flow

sensor. Available settings:

1) POSITIVE: If the actual flow is in the direction of the arrow then the

flow is in the positive direction and the converter will have a positive

flow reading.

2) NEGATIVE: reversed reading of the converter, useful when the

process flow direction is changed so the flow sensor will not need to

be reversed.