6 sensor failure monitoring according to ne43, X / r520/r520x, Operation – INOR IPAQ R520X User Manual

Page 36

5

OPERATION

C520/C520X / R520/R520X

09/2010 • 86B5200001

www.inor.com

36

Designation

Description

C

Check function

S

Not within specification

M

Maintenance required

F

Failure

Table 8: Explanations acc. to NE107

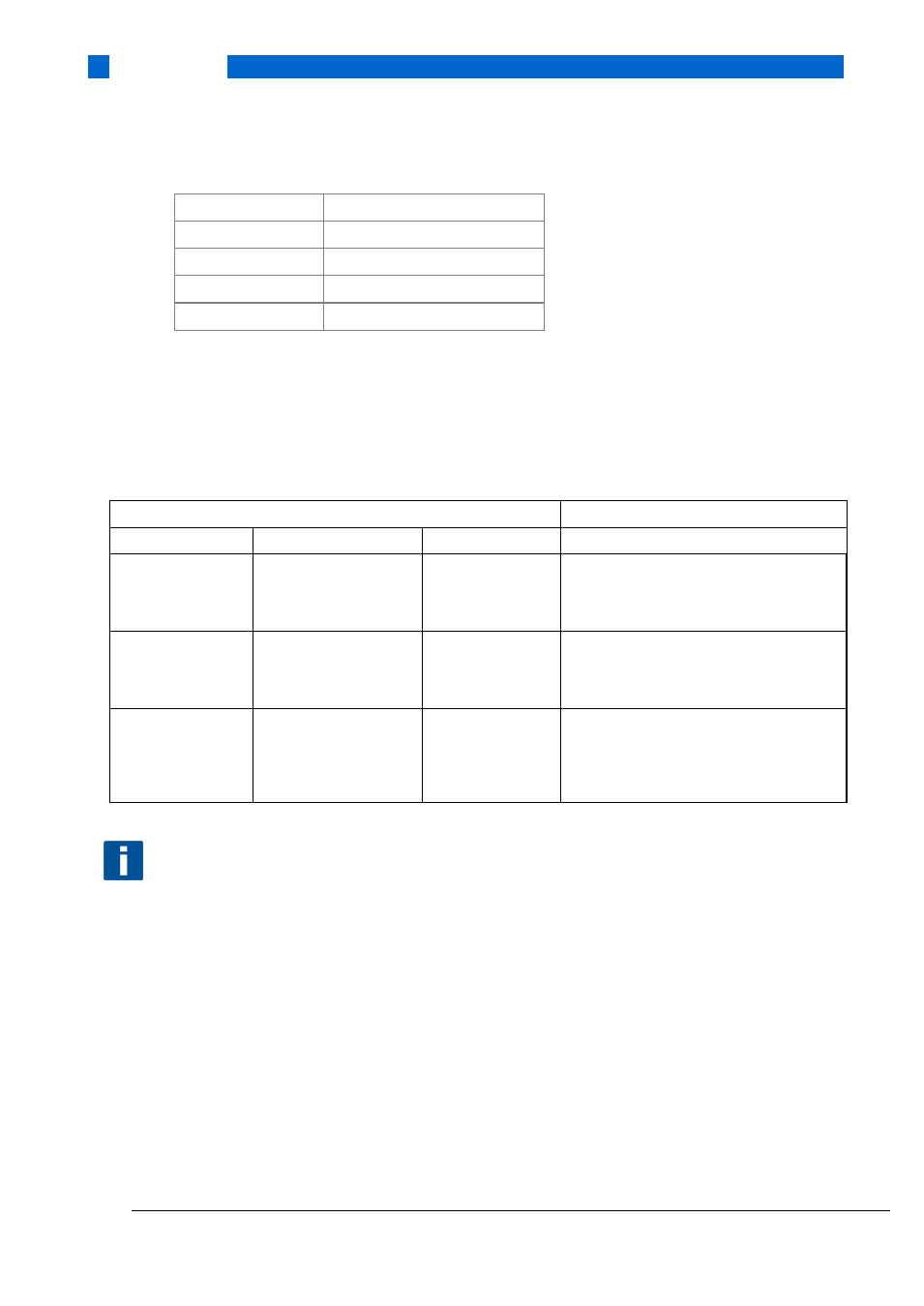

5.6 Sensor failure monitoring according to NE43

There is possibility of the monitoring of the sensor failure in ConSoft. The difference between

the monitoring of the sensor failure in ConSoft and HART is shown in Table 9 below.

ConSoft configuration

HART configuration

Variable name

Possible settings

Factory settings

Comments

Sensor break

monitoring

off, downscale (

≤3.6 mA),

upscale (

≥ 21 mA) and

other value

upscale (

≥ 21 mA)

Configuring of the transmitter in ConSoft for

other value lower than 21 mA is interpreting

as downscale in the transmitter otherwise

as upscale during HART configuration.

Sensor short

off, downscale (

≤3.6 mA),

upscale (

≥ 21 mA) and

other value

upscale (

≥ 21 mA)

Configuring of the transmitter in ConSoft for

other value lower than 21 mA is interpreting

as downscale in the transmitter otherwise

as upscale during HART configuration.

Sensor low Isolation

off, downscale (

≤3.6 mA),

upscale (

≥ 21 mA) and

other value

off

Not permitted for SIL transmitters.

Configuring of the transmitter in ConSoft for

other value lower than 21 mA is interpreting

as downscale in the transmitter otherwise

as upscale during HART configuration.

Table 9: The difference between the monitoring of the sensor failure in ConSoft and HART acc. to NE43

NOTE!

Configuring of the sensor failure in ConSoft for other settings that are not according Namur

NE43 generates an error message!

5.7 Factory configuration and calibration of the C520/C520X / R520/R520X

The C520/C520X / R520/R520X transmitters are delivered with a factory configuration Pt100

(

α=0.00385), 4-wire connection, 0…+100°C / +32…+212°F or configured according to customer’s

requirements (See the Table 3 for detailed information).

Due to the long-term drift of max ±0.01°C or ±0.01% of span per year, a recalibration of the

transmitter is normally not needed. Should you for any reason require the recalibration, the

transmitter must be returned to the factory.